Why your medical device contract manufacturer will likely design your next product

Manufacturing can be treated as an afterthought for medical device design and development companies that do not manufacture in-house. Our vision is a single point of accountability for development clients to ensure a smooth transition from design to manufacturing. No finger pointing.

That vision works. But it doesn’t always start with Design and Product Development. This blog is about our manufacturing clients that came for manufacturing, then engaged our design and development team. Why switch to a medical device specialist manufacturer?

1. They outgrew non-medical device manufacturers. Many companies new to medical devices don’t realize the unique requirements involved. Non-medical contract manufacturers often don`t have the time, interest or capability to register with appropriate regulatory authorities such as the FDA. Their current systems aren’t readily auditable which would require changing too much of their operations.

One client thought they were taking most cost-effective route using a local contract company. After beginning work they discovered the manufacturer couldn`t support their plans to enter the US market. They moved production because we’re an ISO 13485 facility registered for design and manufacturing with multiple projects registered with FDA.

2. They used a design-only firm or designed in-house. The in-house design client found us through a formal selection process. They liked our flexibility to manufacture to their volumes and our design and review services were ideal for on-going design and change control work.

3. Their Volume didn’t fit. Some of our manufacturing clients arrive because big service providers are unable or unwilling to handle relatively low volume, high complexity medical devices profitably. Clients often go through periods of quiet during the process between prototype and approved product. They need to re-start with minimal delays and no interim cost. We’re used to manufacturing small to medium quantities of complicated and regulated devices. And we have lots of other projects to keep us busy during a client’s down-time.

4. They needed to Save Time and Money on an FDA submission. A medical device manufacturer with QMS and design engineers can control prototype runs with regulatory traceability for trials. A recent client came to us when getting ready for clinical trials. After working through various prototypes and revisions, their device will be documented with full traceability.

Here are some reasons why your medical device contract manufacturer will likely be your best design partner.

1. Products often need adjustments in the field. A medical device contract manufacturer engineer will likely make those adjustments. Service field issues, feature requests, and other adjustments are usually made by the manufacturer’s team because change control is easy. The system is in place to meet regulatory requirements. A manufacturing client needed multiple revisions of their current product for incremental improvements to manufacturability and reliability. They liked the results and plan to use our engineers and design team on the revamp of their next generation product line.

2. Quicker to market on next version. The medical device contract manufacturer design/engineer team is in place and ready to go. For initial production runs or even setting up lines with a high volume offshore manufacturer, the product doesn’t have to be re-learned.

3. Technicians are involved with design phase. Medical device manufacturer engineers will be able to design in supply chain, manufacturability, cost, etc. early on with the manufacturing teams so closely integrated. Stocking plans can be put in place during design. Items and processes such as plastics can be figured out, purchased ahead and ready in stock. If there are issues on line when assembly starts, the entire engineering design team is available and able to get things back on line quickly.

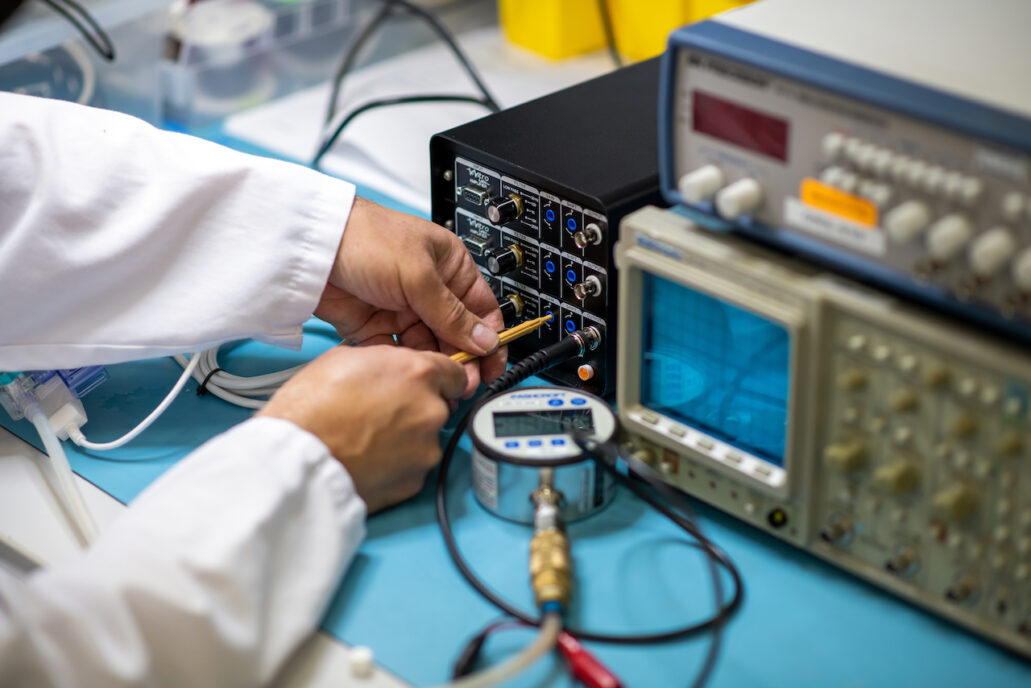

4. Complimentary teams. When your product runs into issues or specific problems with design, the combined engineering and manufacturing team is able to test and provide quick feedback.

Whether manufacturing or design start the medical device client relationship, it’s critical to have a single point of accountability. Clients on the development side smoothly transition to manufacturing. While manufacturing clients gain engineering and design to help with continuous improvement and how to take their product through the next phase of its life cycle or next generation.

Jason Dolynny is a former StarFish Medical Director of Manufacturing. Jason was responsible for manufacturing operations including service, inventory and supply chain management.

Images: StarFish Medical

Learn how to get the most out of working with a contract manufacturer.