What contract manufacturer minimum volume is best?

As your medical device design approaches the manufacturing phase, it can be challenging to decide the best path for production. Should you engage a contract manufacturer or figure out how to set up and start producing your medical device in-house? Many wonder if they need enough product to meet a contract manufacturer minimum volume.

A large volume medical device contract manufacturer typically transfers in completed documentation and processes from the design and development team in order to set up for high volume production. This works great for producing hundreds and thousands of a device with minimal need for changes on the fly.

However, the high cost of set up and initial low volumes are reasons why a large volume manufacturing set-up may not be affordable for many new medical devices. Perhaps you still want the controls and documentation process of a medical device manufacturer in place to meet the requirements of this highly regulated environment. That’s when you ask the question: “What’s the minimum volume required to engage an outside manufacturer?”

Often companies need a small number of initial devices for regulatory testing, to obtain financing, or to seed markets. They feel their only option is to figure out how to set up and build the devices in-house as the minimum volumes required by a large volume contract manufacturer don’t make sense at that time.

Setting up and building a device in-house may be an option, but it also brings challenges. To build even a few first units in house may require hiring additional personnel with expertise in assembly, supply chain, QA/QC and regulatory– especially if the medical devices will be used in a clinical trial or for gathering regulatory data.

When analyzing whether to build/assemble in house or use an outside manufacturer, consider these questions:

- Will it be possible to add required human and material resources to build and document the medical devices without distracting the core team from required design and regulatory path items?

- Will the Supply Chain and Vendor Qualifications completed for this stage of production reduce flexibility for later stages?

- What impact will an initial ramp up of personnel and other resources have on the business if there is a significant amount of time before more product is required.

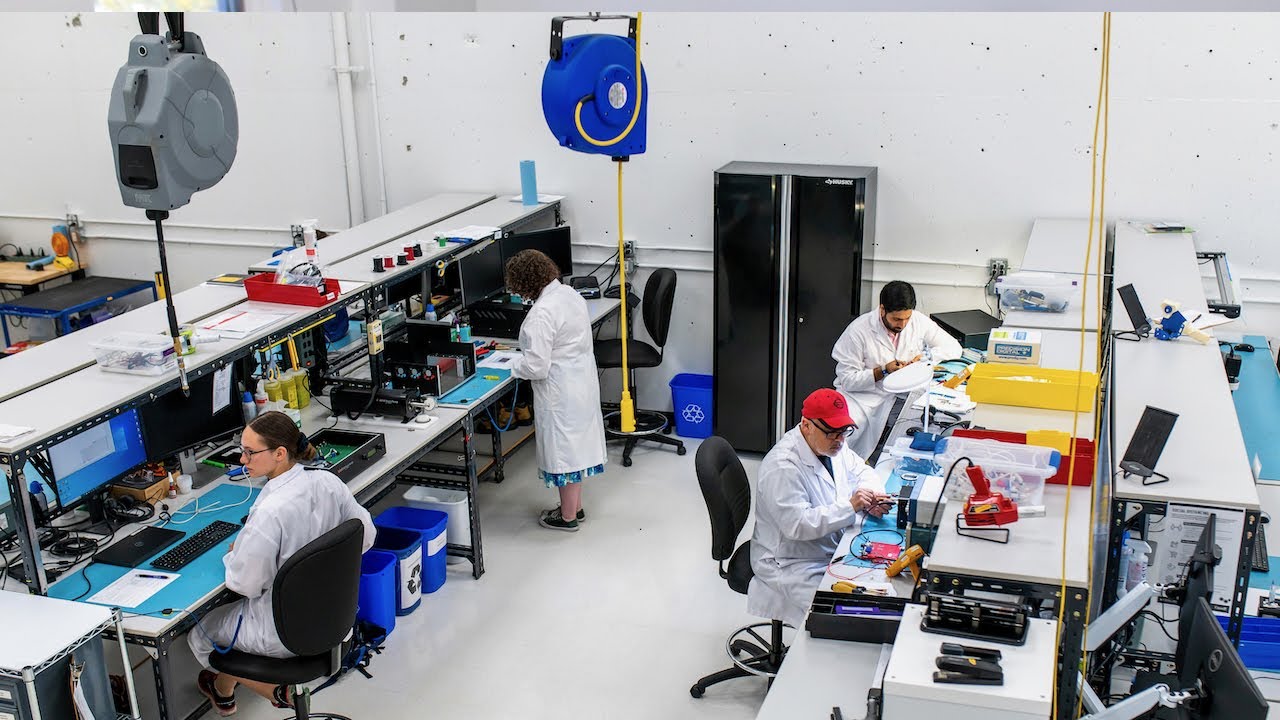

One option to consider is a contract manufacturer that focuses on small to medium volume high complex electro-mechanical devices. They have experience in efficiently transferring product from design to manufacturing. Small to medium volume manufacturers can set up a production line with appropriate controls in place for future increases in volume.

So, what’s the contract manufacturer minimum volume? I’ve helped many companies efficiently and effectively set up and manage initial builds at volumes as low as 5 units. Here are 4 benefits they gained from starting at such a low volume:

- Flexible manufacturing capacity – Contract manufacturers specialize in managing programs with uncertain volumes and staggered start and stops. It’s much easier for them to plan and manage resources over multiple projects that maintains the expertise required for entire programs.

- Trained manufacturing personnel ready to focus on your project when you need them. This allows your core team to focus on growing the business instead of worrying about excess manufacturing labor due to fluctuating market demand or regulatory starts and stops.

- Expert skills and experience to coordinate supply chain strategy, tooling and line set up on a daily basis. Make sure the first run is the focus, while anticipating future strategy and preparing for cost reduction initiatives when volumes change.

- The line is set up correctly the first time– making additional starts and increased volume runs a seamless event.

When faced with deciding if the time is right to engage a contract manufacturer, volumes play a big part, but there are a lot of other things to consider. Make sure you have a solid understanding of your requirements, communicate them clearly, and then the right-sized Contract Manufacturing partner will often emerge as the most appropriate option. For more information, check out Get the most out of working with a contract manufacturer.

Jason Dolynny is a former StarFish Medical Director of Manufacturing responsible for manufacturing operations including service, inventory and supply chain management.

Images: StarFish Medical