Taking a medical device idea from concept through to manufacture

Are we done yet (concept through to manufacture)?

It’s a simple enough question. But the answers, like most questions, aren’t as easy. What is often missed in the translation is that there are varying degrees of done. In taking a medical device idea from concept through to manufacture there are a few ‘done’s along the way, and that takes time and effort. And time is money.

You’re working one day, and come up with a fantastic idea. It solves a problem, and you think you have the answer. You mock up some ideas and concepts, and make a prototype. It works, so you exclaim, “We’re done!” Well, not quite.

The proof of the concept is just that – it illustrates the idea, the concept that solves that initial problem. The design phase takes that proof of concept and turns it into something that looks like a product. Some more prototypes are made, and these look and feel like you’re close to the finish line. Industrial design has been completed. In medical device development, that also means a fair degree of verification of the concept, and validation that the product is effective in its intended use. Risk assessments analyse the safety of the device. The device works, feels nice, and looks nice. Let’s get it to market, you exclaim! We’re done! Still not yet.

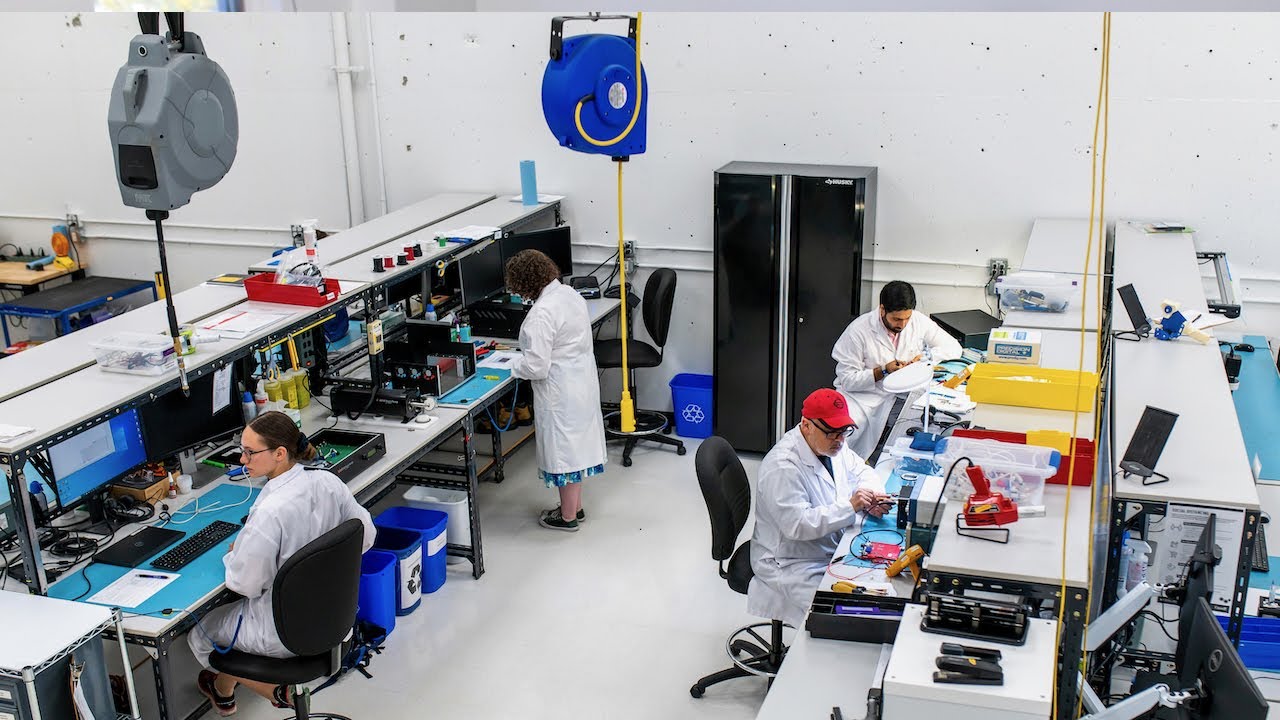

Making one of something, and getting it to work, is not the same as manufacturing 1000, or 100,000, and having them all work. Processes that work for prototyping can be too costly in higher volumes. A controlled engineering build is not the same as an assembly line. On the assembly line, the process must be repeatable, and repeatable by everyone. Anne cannot build it differently than Bob. Steps which are currently known only to highly trained people now need to be captured so there is no interpretation and the product is built the same way every time by everyone.

Consider the act of stapling pages together. In such a simple process, that many of us do without thought, there are variables which are undefined. Which corner? Parallel to an edge, or 45°? How far off 45° is still acceptable? What if the stapler breaks? Now imagine that stapling is a critical process and failure could have safety implications. Ambiguity and variation are not options.

It’s human nature to lose focus performing the same tasks over and over. Changes which can eliminate these types of errors should take place in the development phases. Jigs and fixtures need to be designed, built, and validated; process controls put in place; vendors qualified and their processes validated. FDA submission needs to be completed for the US market, and CE testing for Europe.

Now that we can build the product, build it the same every time, and ship to the end user. Surely we’re done now?

Almost. The finish line is definitely in sight.

The last thing is setting up service and warranty. Try as we might, failures will occur, or technical questions will be asked. Device maintenance schedules may be required. Service and warranty plans, procedures, and paths will need to be created linking end users back to you. When all those are in place, we’re finally done.

(… and ready to begin sustaining engineering).

Dana Trousil is a StarFish Medical Mechanical Engineering Team Manager. He has successfully launched many products, from small volume production up to moderate volumes (up to 1 million parts per year), with experience in injection moulding and a variety of other processes.

Image: 22486375 / vaeenma – CanStockPhoto

Tools to Select the Right Concept in Medical Device Development