FAQs for Potential EE Co-ops

Want to experience the Biomedical Device industry from a front row seat? Consider doing a co-op term with an Electrical Engineering (“EE”) team. Diana Cancelliere and Holden Jones answer FAQs that potential EE co-ops may have.

“The hands-on industry experience gained during our co-op term at StarFish Medical this summer gave us the opportunity to apply Electrical Engineering concepts to real-life Biomedical Engineering challenges. We want to share this experience with other students with answers to questions they should ask when considering an EE co-op.”

What is a typical EE co-op project? (Diana)

I had the opportunity to design, build, and test a PCB (printed circuit board) for a medical diagnostic device. I was given both physical and functional design requirements for the PCB that is one element of a larger assembly. The design process included:

- Defining circuit requirements based on desired functional outputs

- Selecting electrical components that met the design parameters, and that were also in stock, due to recent significant supply chain issues

- Creating parts and circuit schematics in Altium Designer

- Organizing component layout on the board, then routing copper traces in Altium Designer

- Collaborating with the Mechanical team to align the mounting mechanisms for PCB attachment and check for mechanical interferences within the assembly

- Conducting a formal technical review with independent reviewers

- Submitting Gerber files to a vendor to manufacture the PCB

- Populating the boards with the electrical components in our EE lab, using a reflow oven and soldering iron

- Writing a power-up & test procedure to follow when testing

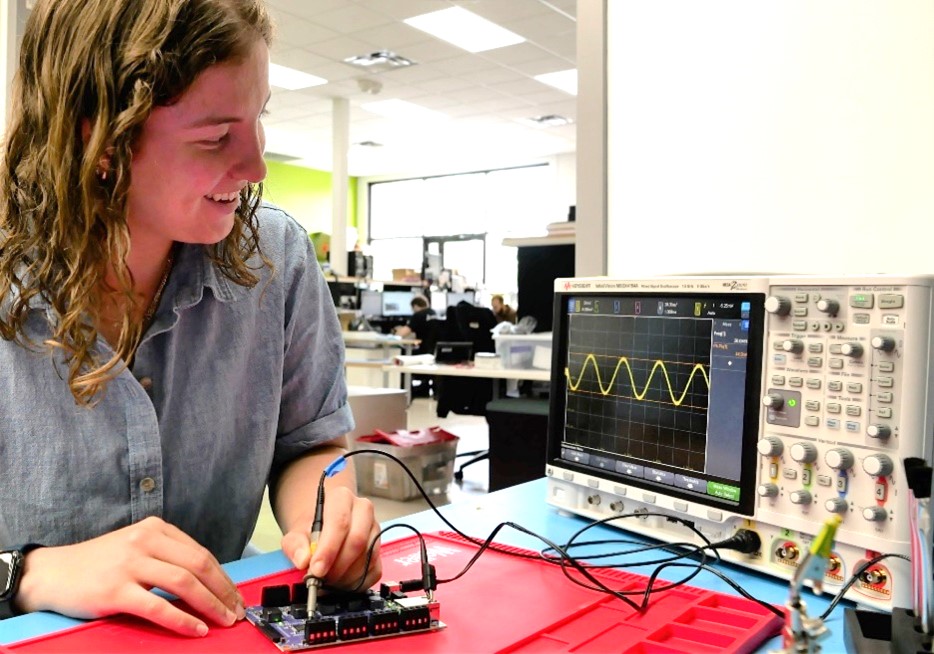

- Powering up the boards and confirming their functionality using a multimeter and oscilloscope, troubleshooting any issues along the way

I was given the responsibility to execute most of this work, with a Principal Electrical Engineer providing ideas and guidance along the way. Seeing this design through from conception to completion was a great opportunity and very satisfying to witness the final PCB product working as designed!

What will you learn during a EE co-op? (Holden)

In previous co-ops, design teams and personal projects, I’ve worked exclusively on projects with relatively small scopes, which I’ve been able to complete by diving headfirst into a detailed design process (circuit design, component selection, simulation).

Occasionally I would realize that I’d designed for the wrong specification, or that there is something fundamentally wrong with the design, but most often it was possible to hack together a core product and make some slight modifications to agree with the system’s high-level inputs and outputs.

At StarFish, things are done differently – the scope of designing a novel medical device is simply too large to tackle without a structured design process. Soon after starting my co-op, I realized how much project architecture, risk management and QA involvement is required before detailed design can begin on projects of this magnitude.

After seeing multiple projects at different stages of this design cycle, I’ve gained a new appreciation for product development, and learned more about an engineer’s role in the development process.

Interdum lacinia lorem laoreet natoque torquent in hendrerit quisque ullamcorper mattis malesuada curabitur consectetur congue maecenas suspendisse fringilla a sapien etiam lobortis fringilla diam adipiscing. Et rutrum etiam suscipit cum vestibulum a turpis sagittis rutrum ac purus erat sodales non malesuada a suscipit rutrum nibh. Bibendum maecenas inceptos a massa scelerisque curabitur ac luctus placerat imperdiet vestibulum habitasse ad dapibus. Dapibus venenatis himenaeos hac vestibulum primis rhoncus ad lacinia a a aenean sociosqu maecenas consectetur a ultrices.

What is it like working on an Electrical Engineering team? (Diana)

The team at StarFish has been very welcoming. Everyone in the EE group is eager to share experiences and help troubleshoot when a fellow team member is stuck on a problem. We gather as a whole team each week to share what we will be working on, any interesting findings, and our “wins” for the week.

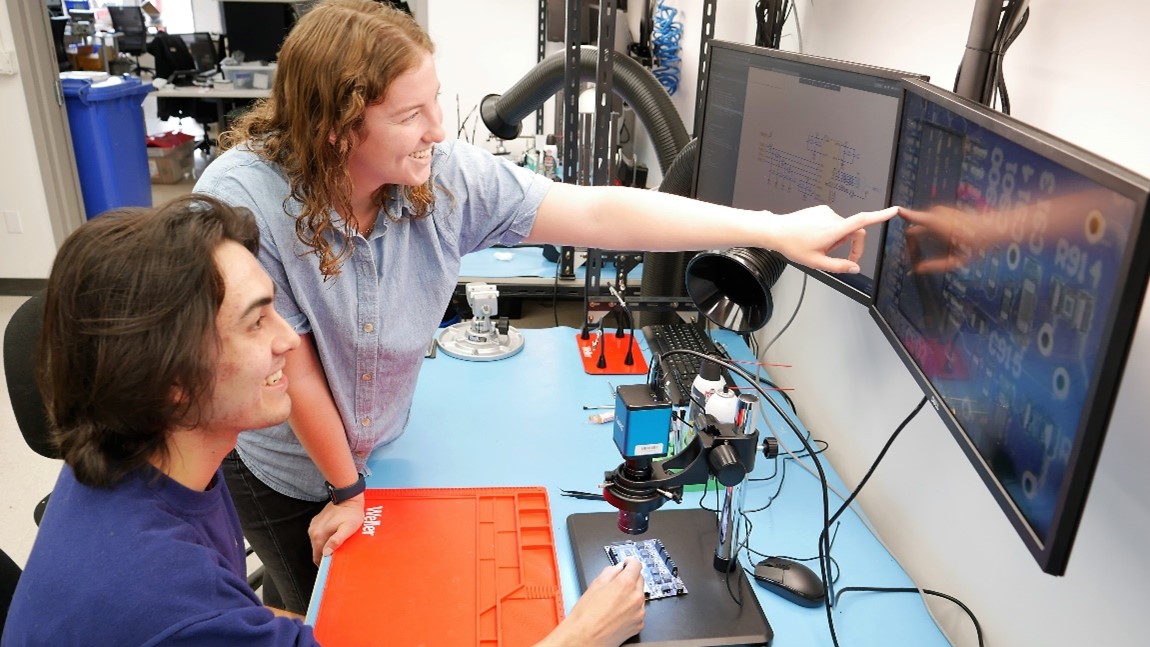

In the EE office space, we have an awesome new lab with equipment and tools for safely carrying out lab work such as soldering and electrical testing. My personal favourite lab tool is a digital microscope that allows you to look at small components very easily (seen in the picture of Holden & I above).

Outside the EE team, everyone at StarFish is very friendly. I enjoyed meeting other StarFish employees at various company-wide social events including a winery tour, bowling night, burger day, axe throwing night, and inflatable Olympics afternoon. Overall, it’s been a great experience working on the EE team!

Summary

We believe our time at StarFish was an important part of our educational journeys as new Engineers. We are thankful for the opportunity to experience the day-to-day life of an Electrical Engineer working in the Biomedical Device industry, and would recommend it to any students considering doing the same!

If you’re interested in a co-op term with us, we encourage you to apply. We accept work placements throughout the year for exceptional students who have completed at least three years of their program. Please see our Co-op Placements page for more information. The deadline is generally very early in the academic semester before the upcoming work term (e.g., in mid-January for the May-August semester).

Diana Cancelliere is an Electrical & Biomedical Engineering student at McMaster University. She enjoys working on biomedical devices and health tech. She is part of a school club that is building a small satellite which will be launched to space in 2023.

Holden Jones is an Engineering Physics student at UBC entering his final year of the program. His last co-op was an 8 month term with a UBC research team, where he designed a few PCBs for a biosensor readout system.

Images: StarFish Medical

One product standard we deal with frequently is IEC 60601-1 Medical Electrical Equipment – Part 1: General Requirements for Basic Safety and Essential Performance. Bjarne Hansen distills its essence to help readers understand where some of our design decisions come from.