The Role of Lipid Nanoparticles in Vaccine Production

The recent COVID-19 pandemic has been a reminder of how effective vaccines are for protecting public health and saving healthcare system resources.

The world was brought to its knees at the beginning of the pandemic with countless heartbreaking deaths, but this tragedy catalyzed the accelerated development of different vaccines through collaboration between governments, pharmaceutical companies, and scientists.

The speed at which these vaccines were developed, tested, and approved has been remarkable. In the past, it could take years, even decades, to develop a new vaccine, but thanks to advancements in drug delivery and nanomedicine, this was achievable with unprecedented speed.

Fighting Diseases Begins with Understanding Our Bodies.

Vaccines are a crucial tool in the fight against infectious diseases, as they play a central role in reducing the risk of hospitalization. To better understand how vaccines work, it is essential to understand how the body fights a new disease. Our body is a great learner, and this is the key concept behind vaccines.

Generally, when the body is infected with an unknown virus, the immune system utilizes its power to fight the infection. Various immune cells, including B-lymphocytes and T-lymphocytes, get triggered by the pathogen’s antigens to differentiate into antibody-producing and memory cells. The memory cells (T-lymphocytes) retain a memory of the pathogen’s antigens to react immediately against future infections.

Unfortunately, sometimes the body fails to fight the invader and requires external help.

How Vaccines Work and the Types of Vaccines

Vaccination mimics the natural infection process by supplying the body with a weakened or inactivated version of the virus. This process does not cause illness but helps the immune system develop immunity against future infections and store T-lymphocytes, memory cells, and B-lymphocytes, antibody-producing cells, that know how to fight the virus.

Many approaches have been used to design vaccines based on information about the pathogen using live-attenuated and inactivated pathogen, a subunit of the pathogen, or a viral vector. Live attenuated vaccines deliver a weakened version of the virus, whereas inactivated vaccines work by inactivating the virus during the vaccine production process. Subunit vaccines utilize specific antigenic components (like the spike protein), known as subunits, of the pathogen rather than the actual virus.

Viral vector vaccines use a genetically modified version of a non-pathogenic virus to deliver genetic material about the target pathogen to the cells.

Nucleic acid-based vaccines have recently emerged as a promising alternative to conventional vaccines. mRNA vaccines deliver engineered mRNA to the host cells to teach cells how to synthesize the viral protein and elicit an immune response.

However, delivering the mRNA into the cytoplasm of the cells is challenging because of their large size and negative charge that hinder their uptake. Therefore, lipid-based nanoformulations have emerged as safe and effective delivery vehicles for active pharmaceutical ingredients (APIs).

Currently, more than ten liposome-based medicines are approved for clinical use, including Doxil®, the first liposomal product approved by the FDA.

Lipid-based Nanoformulations as APIs Vehicles

Liposomes and Lipid nanoparticles (LNPs) are composed of one or more types of phospholipids, which are molecules that have a hydrophilic (water-attracting) head and a hydrophobic (water-repelling) tail. This amphiphilic structure allows liposomes and LNPs to self-assemble into a spherical bilayer structure with discrete hydrophilic and hydrophobic compartments.

Liposomes are mostly unilamellar lipid systems with an aqueous core, whereas LNPs are multilamellar lipid systems with a polymeric layer. They are widely utilized as a means of delivering hydrophilic and hydrophobic APIs. Hydrophilic APIs are enclosed within an inner aqueous phase, while the hydrophobic ones are either dissolved or incorporated within a lipid compartment.

Different lipid-based vesicles were synthesized by systematically varying the lipid head and tail structures with the addition of ionizable lipids that promote self-assembly into nano-sized vesicles, cholesterol which stabilizes their structure and enhances their integration with biological systems, and lipid-linked polyethylene glycol (PEG) that acts as a surfactant to prevent particles’ aggregation and protects the particles from the non-specific endocytosis by immune cells, hence increasing the LNPs in vivo half-life[*].

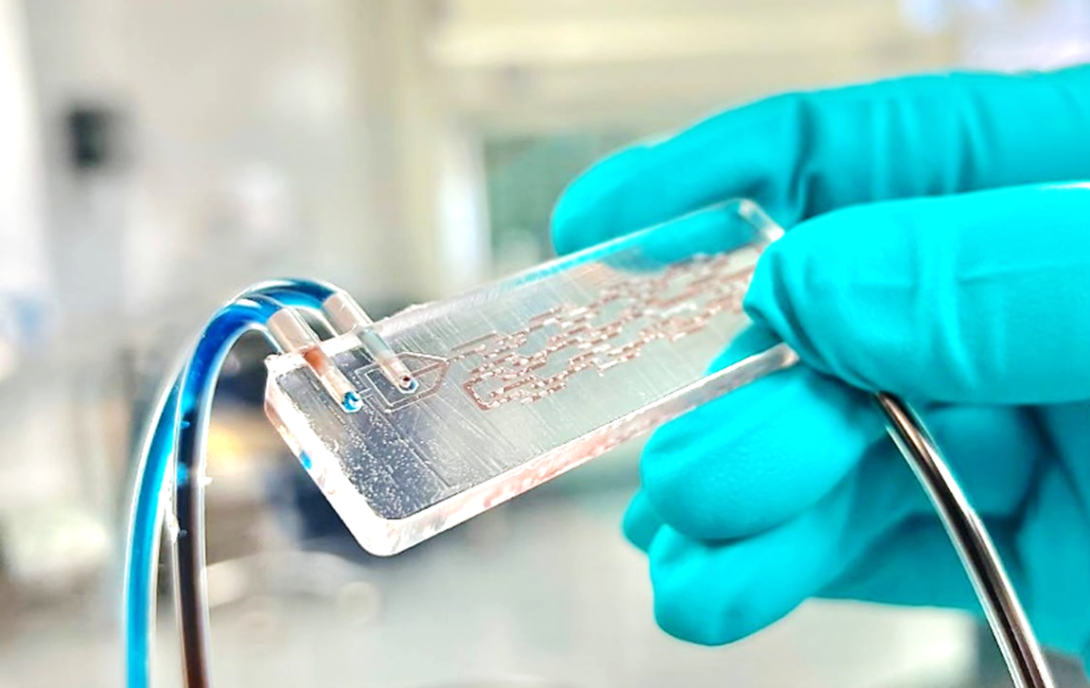

Leveraging Microfluidics for Efficient Lipid Nanoparticle Synthesis

The synthesis of LNPs can be achieved through various bulk methods, including but not limited to multi-step extrusion, sonication, and ethanol injection. These processes often lack precise size control of the nanoparticles and their polydispersity. They produce vesicles with low encapsulation efficiency and are prone to batch variability, requiring additional labour-intensive isolation and fractionation steps during manufacturing.

LNP size and polydispersity can have a crucial influence on the efficacy of the LNP therapy in vivo. For these reasons, microfluidic technology has become widely adopted for producing LNPs. Microfluidic LNP production systems offer several advantages: including precise control over particle size and mixing time, lower size dispersity, ease of scaling up production, and the ability to generate a continuous, scalable manufacturing process.

A variety of different microfluidic devices have been developed to produce small and stable LNPs, and many of these are currently available off-the-shelf.

To synthesize LNPs, microfluidic devices rely on the ethanol-dilution concept, where the lipid solution is dissolved in ethanol and mixed with an aqueous phase containing the API. Once both solutions are loaded into a microfluidic device, the lipids will self-assemble into nanovesicles depending on the ethanol dilution rate and the flow rate ratio of the two solutions.

The rate of ethanol dilution directly affects the size of LNPs, with a faster rate resulting in smaller LNPs. Several microfluidic devices have been developed for LNP production, including T or Y-shaper junction mixers, hydrodynamic flow focusing (HFF), herringbone micromixers, bifurcating and baffle mixers, and Tesla mixers. Herringbone micromixers promote a faster ethanol dilution rate; however, the mixing performance is compromised with higher flow rates, limiting the production throughput.

To enable large-scale production of lipid-based nanoparticles, techniques such as parallelization or high lipid concentrations are employed. For instance, Precision NanoSystems (Vancouver, BC, Canada) has recently released the NanoAssemblr system, which uses a NxGen microfluidic bifurcation mixer for the high-throughput production of LNPs.

Concluding Remarks

Lipid-based nanoformulations are the technology behind the unprecedented speed of vaccine production. These vesicles are used as drug delivery carriers to encapsulate drugs and other molecules, such as nucleic acids. mRNA-based vaccines depend on delivering mRNA to the cytoplasm of the host cell effectively.

Microfluidics offers an excellent platform for the high-throughput production of homogenous RNA-encapsulated LNPs, including mRNA and siRNA, with low batch-to-batch variability.

The exciting development of a range of new gene therapies that require novel drug delivery systems means that microfluidics and LNPs will continue to shape the healthcare system into the foreseeable future.

[*] The time taken for the concentration of the drug to decrease by half in the body.

Image: StarFish Medical

Khaled Youssef is Bio Services Microfluidics Engineer at StarFish Medical.