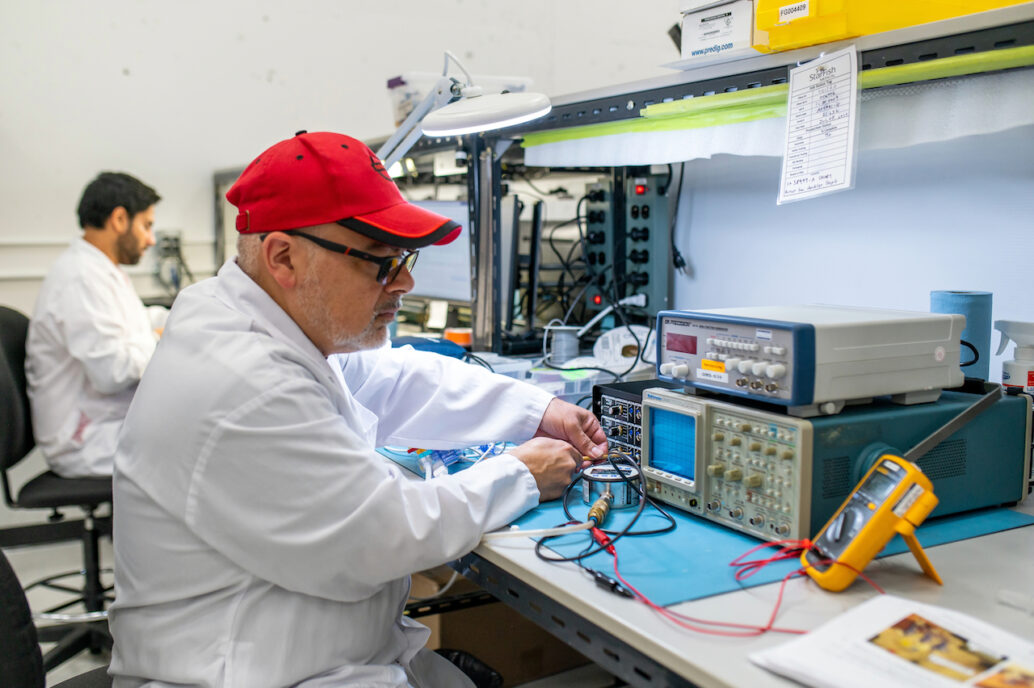

Small Manufacturing

Ever since I entered the world of product development, I’ve heard countless pitches from sales people who work for large contract manufacturing service providers – pitches that focus not so much on their capabilities and unique/real value, but more about the size of their organizations. The schtick goes something like this: “We have 10 factories, with 3,000 workers, the list of equipment we have in each plant is blah, blah…blah…we make all kinds of products for this company and that company… blah, blah, blah”.

It’s at this point in their presentation, when they start to list all the equipment that resides in their factories, that I start to feel really sleepy and want to nod off. Absent from many of these pitches was an appreciation and understanding of my business (because that would take some work in advance) and how what they do actually adds value to my product development and commercialization efforts.

The question I’m always left with at the end of these presentations is: Is bigger always better? What if I’m a small company with a need to manufacture in low volumes or very complex products….who helps me then? Isn’t there a partner for a small, high value small manufacturing company who needs to manufacture low quantities of really complex things?

If this is the place in which you find yourself, you need to know that you do have choices. There are small manufacturing companies out there who know how to professionally handle and execute upon this type of scenario.

If the above story is your story and you need to qualify a small manufacturing contract manufacturer, I would suggest that you consider the following list of 10 questions as a first step in the qualification process:

- If the product you manufacture has design and engineering complexity – ask, “What is the level and type of in-house engineering support offered by the potential partner?”

- Does the manufacturing partner have expertise in your product category (optics, electro-mechanical, software, etc.) ?

- What market and product categories does the CM usually deal with? Will you and your business be part of a grand experiment?

- What is the average size of their customer engagement? Where does your business volume fit into the mix? This is an important question to ask, since it largely determines the level of ongoing (‘after the deal is signed’) support you will receive.

- What happens if your product needs a certain level of customization (per product/customer) with each batch? Does the CM have the flexibility to deal with frequent change (feature customization, schedule, etc.)?

- Does the CM have rigid supplier agreements/ requirements (components, for example) that force you to work with volumes and vendors that don’t align with your specific small manufacturing needs?

- Do they have expertise in testing (mechanical, material, software, etc.)?

- Are there systems and processes in place to track and report quality and performance metrics?

- Is your information and product technology (IP) secure?

- If you’re making a medical device, do they have personnel experienced in regulatory compliance and all the requirements/processes/procedures that go along with that?

The above list is not comprehensive, but it’s a good first cut at understanding and determining if small manufacturing is the best contract manufacturer for your important products.

David Dobson is VP of Business Development at StarFish Medical. He brings consumer electronics and medical device experience and lots of passion to help potential clients understand what it takes to turn ideas into medical devices. See the results of some of his efforts in Our Work pages.

Photo Credit: StarFish Medical

Learn how to get the most out of working with a contract manufacturer.