Resource Centre

Discover a wealth of knowledge and insights from the experts at StarFish Medical. Our Resource Centre offers product development tips, reviews of new and cutting-edge technologies, and in-depth articles on regulatory updates and compliance in medical device development.

-

A structured, well-documented design review process is a critical component of successful product development, particularly in the medical device industry.

-

In medical device development, we deal with complex projects that span multiple disciplines, timelines, and regulatory gates. It’s a constant balance between moving fast enough to innovate, but slow enough to stay compliant.

-

Ariana and Mark walk through FDA-approved options and explain how to select the right one for your product. From metals to plastics and electronics, not all devices can handle the same process.

-

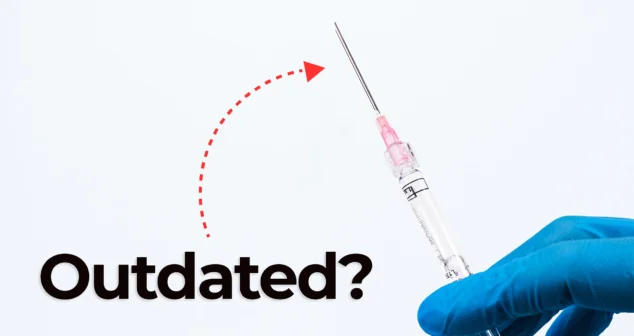

Nick and Nigel dive into the world of jet injector drug delivery. This needle-free method, made popular in science fiction and real-world vaccines, is still used today.

-

Many clients now request their devices to look and feel like Apple products. But achieving that level of simplicity and elegance is not as easy as it seems.

-

Nick and Nigel explore a surprising approach to injection pain reduction using suction technology. What started as an unusual product order at StarFish Medical led to important insights on improving patient comfort during injections.

-

You have a great MedTech innovation idea and are trying to decide whether to build a team to commercialize a medical device…

-

Nigel and Nick explore microneedle drug delivery—a growing field in medtech that aims to improve patient comfort and treatment compliance. While the term "microneedles" may sound futuristic, this technology has been around for years.

-

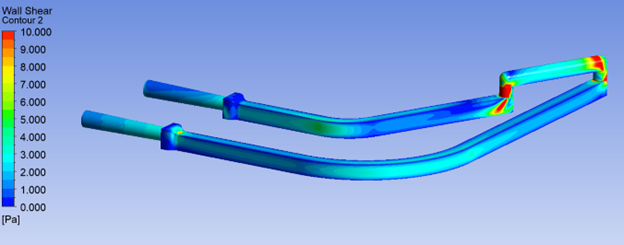

The impact of shear stress is critical to effectively design medical devices that handle biological fluids such as proteins or cell culture media. For example, non-physiological shear stress (NPSS) on blood is a key factor because hemolysis (cell rupture) could occur due to accumulated stress.