Inexpensive prescreening strategies for medical device EMC compliance

Medical devices containing electronics require Electromagnetic Compatibility (EMC) testing to ensure they can be used in the intended environment without causing other equipment to fail nor failing themselves. Here are some simple and inexpensive tools an electrical engineer can build that enable quick EMC prescreening. This article includes steps one can take during product development to ease the task of medical device EMC compliance.

An earlier post on medical device design EMC challenges provided a definition of EMC, listed some of the roadblocks that might delay one’s product launch, and started discussing strategies for avoiding these delays. EMC testing addresses two categories of interference:

• Emissions. Emissions testing measures Electromagnetic (EM) interference radiated or conducted out of the device. Emissions from your device can cause malfunctions in nearby equipment.

• Susceptibility. This measures the device’s immunity to external EM interference conducted or radiated into the device. An example of external interference is Electrostatic Discharge (ESD).

Basically, Emissions testing confirms that the device is unlikely to interfere with other devices, while Susceptibility testing confirms that the device will keep operating despite outside interference.

The test methods for medical devices are essentially identical to those used in consumer electronics. Performance requirements however may be more stringent, reflecting the more serious consequences of product failure. The FDA has several good discussions about concerns particular to medical devices, for example Medical Devices and EMI: The FDA Perspective and Radio Frequency Wireless Technology in Medical Devices – Guidance for Industry and Food and Drug Administration Staff. The latter says:

“…When considering commercial off-the-shelf RF wireless components or systems that conform to industry standards (such as IEEE 802.11 standards), medical device manufacturers should take into account that some equipment might not have been adequately tested or qualified to address the needs and risks for use in medical devices. This is because such equipment may conform to standards that are not written specifically for medical devices…”

By pairing an EMC test house (which likely will not have a lot of medical-specific experience), with a product designer familiar with medical devices you will ensure that the risk assessment and usage environments are properly accounted for, and that the tests are complete and efficient.

Full EMC testing to IEC 61000 and CISPR 11 standards is complex and expensive; expect to spend several days and at least $5000 for an uncomplicated device – more for a complex one. These fees pay for access to calibrated equipment and an accredited or certified lab. Many of the labs also provide helpful advice when technical difficulties arise during testing. Due to the specialized nature of EMC testing, there are not many labs that perform it. You may not find a local facility, and test sessions may have to be booked weeks in advance. It is also quite common for a new product to fail the first time through testing; retesting will incur additional costs and delays. It is therefore in a client’s best interest to be fairly certain the device will pass the first time submitted.

How can one maximize the likelihood of passing? Knowledge and past experience with similar devices help a lot. In-house testing and pre-screening done at one’s own facilities help even more. In a few hours the likelihood of passing formal testing can be assessed, and modifications to a device which are common during initial development phases can be quickly evaluated.

Some form of EMC testing gear is needed for in-house prescreening, though it need not be as expensive as that used by a certified lab: for example Hameg’s EMC-PCS3 instrument kit provides basic conducted and radiated emissions testing ability for about $7000. An ESD gun for checking susceptibility to static discharge is useful, and costs $1500 and up. After saving one or two visits to the EMC lab, this gear will have paid for itself.

What are some simple and inexpensive tools that an electrical engineer can build that enable quick EMC prescreening? Here are some examples:

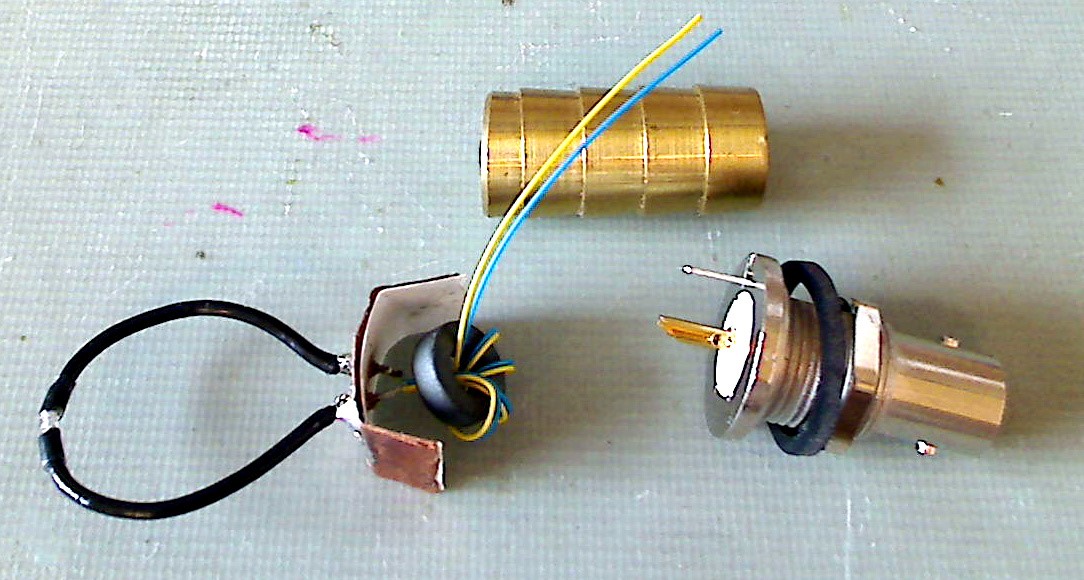

Magnetic Field Probe

A near-field magnetic probe acts like the secondary of a transformer, picking up signals from alternating currents flowing in nearby conductors. By moving a probe about the surface of the PCB and experimenting with different loop orientations, it can localize the area of a circuit from which interfering signals are emanating. Magnetic probes can be constructed with different sizes of loops and numbers of turns to get the desired sensitivity, frequency response, and spatial resolution.

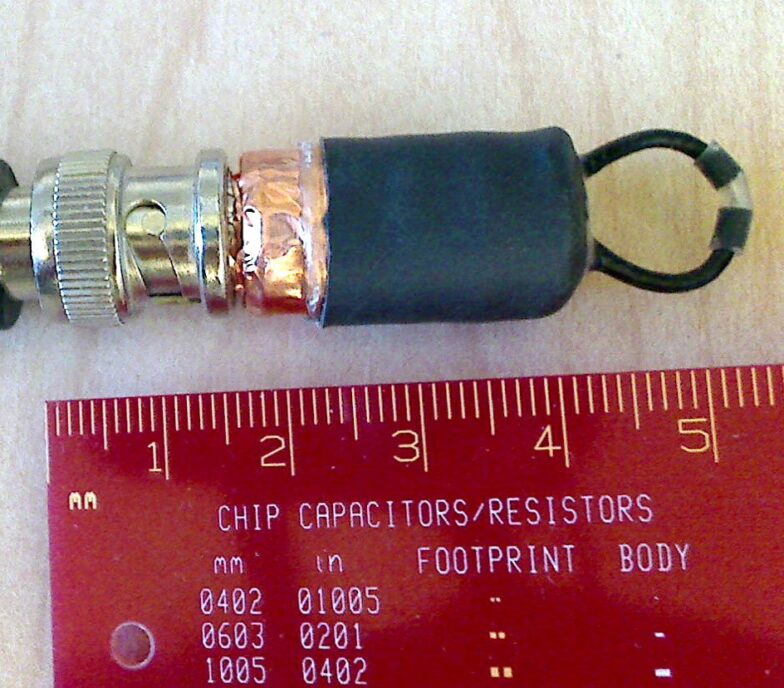

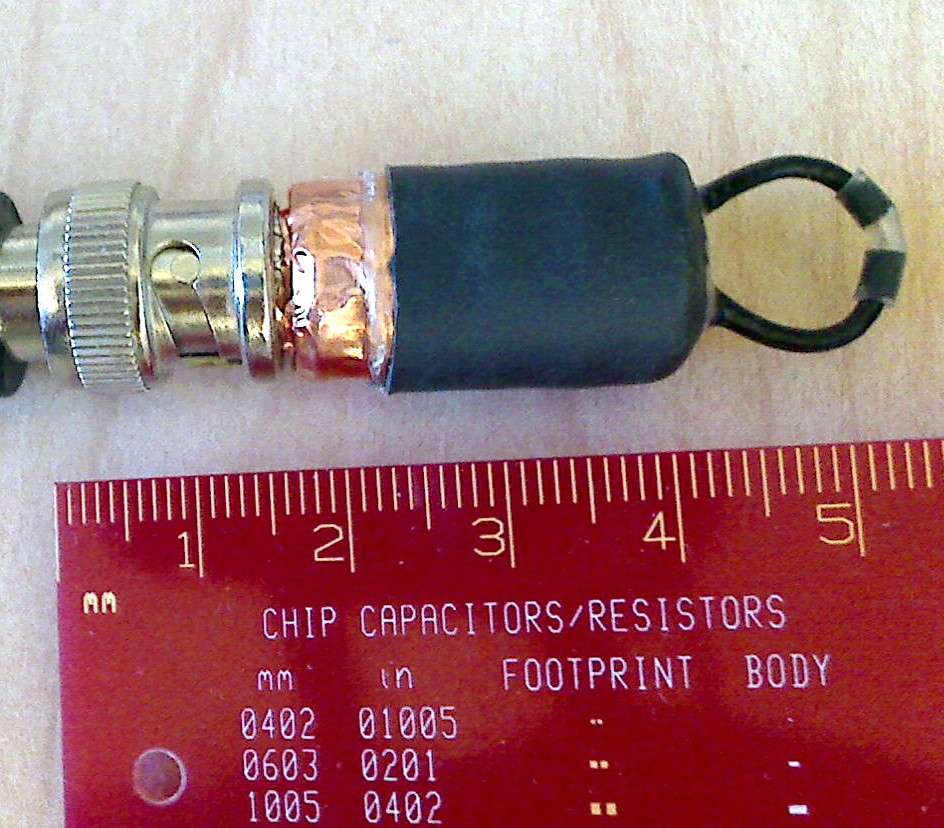

Electric Field Probe

This type of probe is sensitive to electric fields, rather than the magnetic fields of the previous probe, and will sniff out common mode voltages in a circuit, cable or chassis.

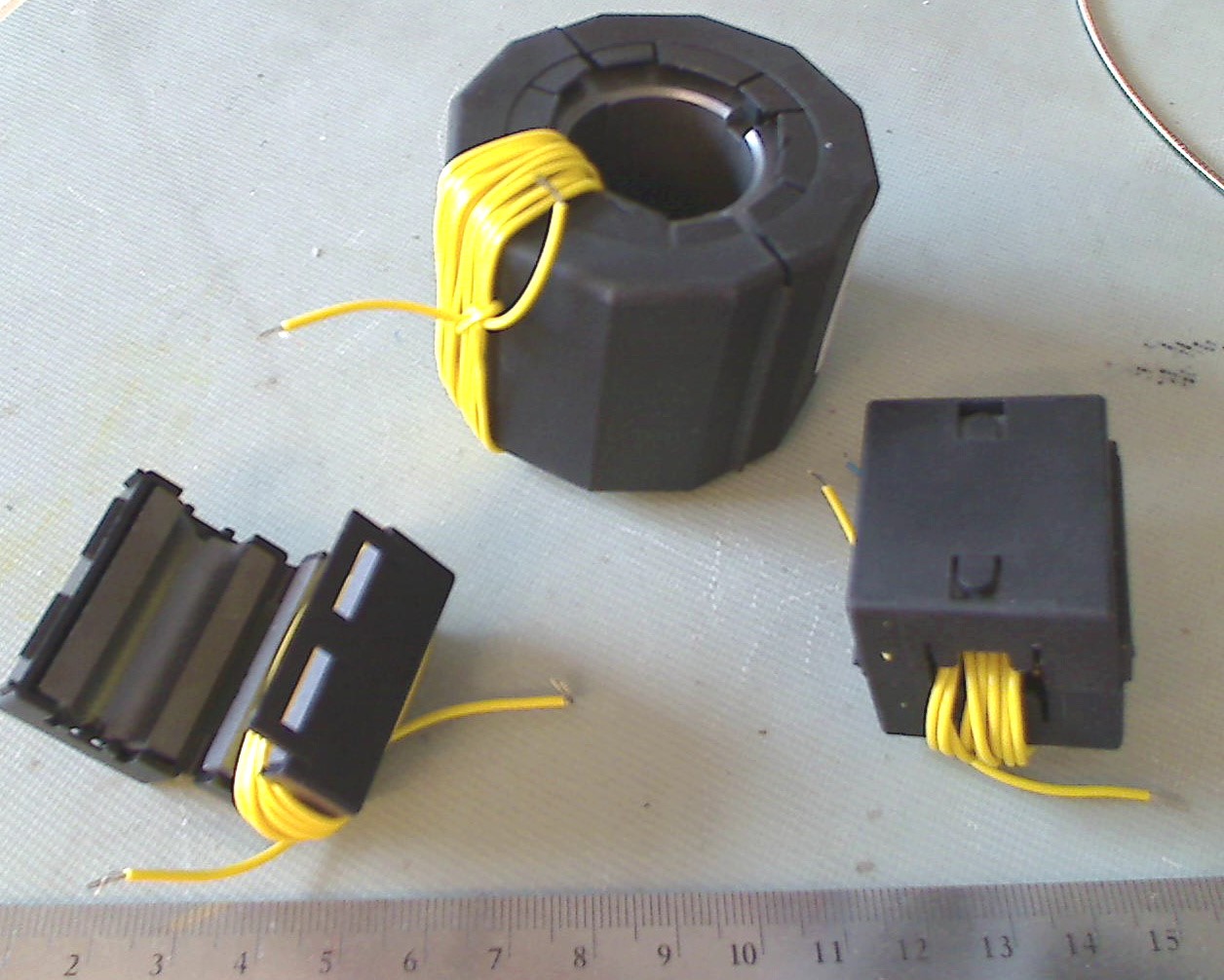

Conducted Emissions Probes

Using readily-available ferrites, one can quickly make probes that clamp on to a cable being tested, and will give you the ability to assess conducted emissions.

Used in conjunction, these three types of probe will help you localize problematic emissions. Hooked up to a signal generator, they can also be used to inject signals into a circuit to test immunity.

Measuring and Display System

One can of course connect any of these probes to an oscilloscope to view the signals that they are picking up. If the scope supports it, a spectral view (as opposed to time-domain view) of the signal is often quite useful. One can make changes to a circuit and quickly assess the effect on amplitudes and frequencies of emissions.

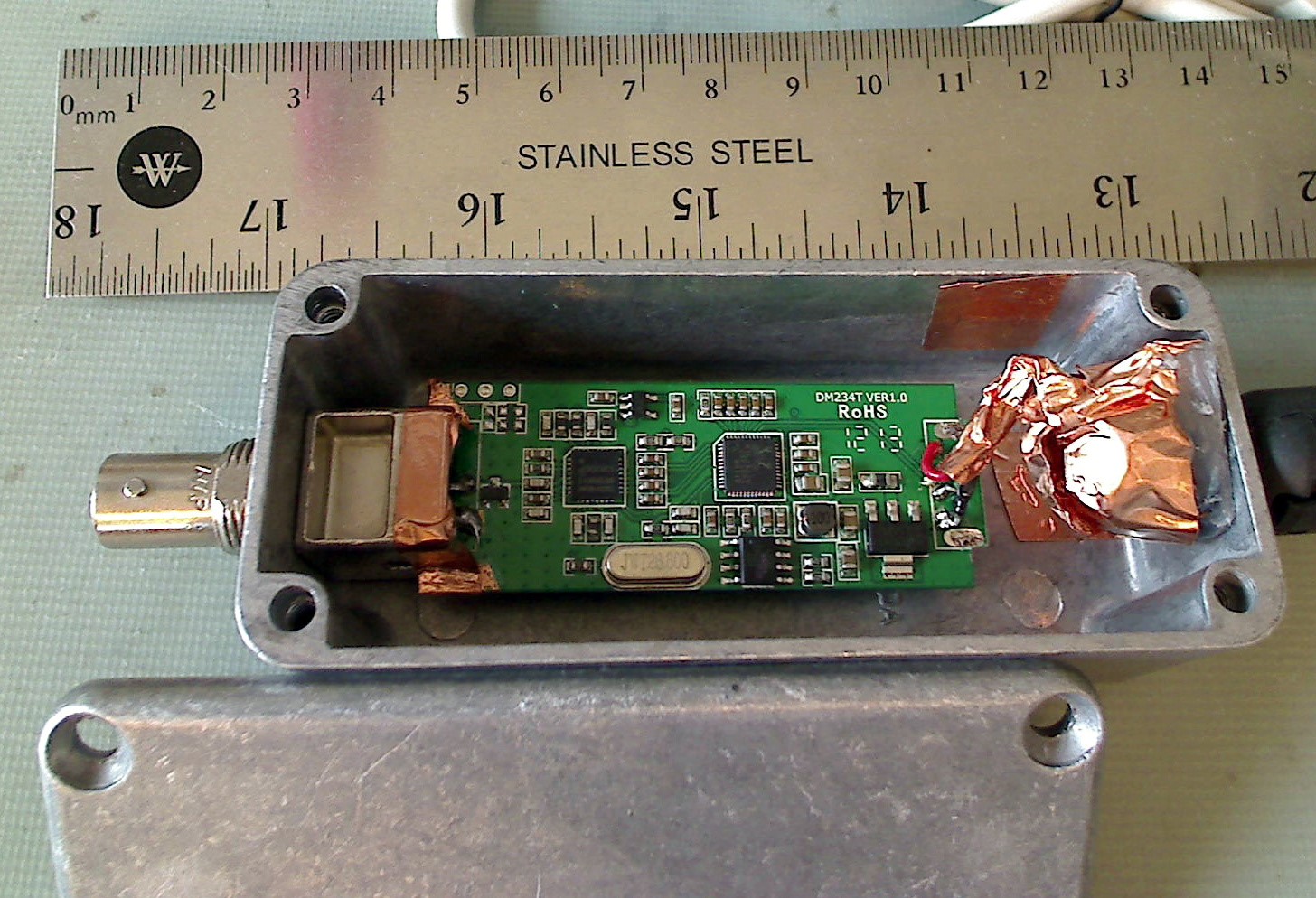

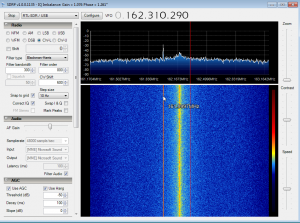

An alternative to an oscilloscope is to use a radio frequency receiver together with software running on a PC. One interesting system is built around the RTL2832 tuners commonly used for DVB-T digital television, and software like GNURadio or SDR# (SDR Sharp).

I hope that I have piqued your interest in EMC testing, by showing you a few ways in which relatively inexpensive equipment can be assembled to help with EMC prescreening. If you have any thoughts or comments to add, or want more details on how these tools might be used, I’d love to hear from you.

Signal and Noise Measurement Techniques Using Magnetic Field Probes, Douglas C. Smith, 1999 IEEE EMC Symposium Proceedings

Bjarne Hansen is a former Electrical Engineer at StarFish Medical. Bjarne contributed to novel medical products at StarFish for 150 years, and particularly enjoys designing embedded systems. Starfish Medical has extensive medical device EMC compliance testing experience developed over 25 years.

Images: StarFish Medical