Despite a high number of university or college graduates looking for entry level work in the tech industry, companies still report difficulty in hiring [1]. This is in part due to a medtech skills gap between entry level work and university training. Industry involvement in academia has the power to address this issue. Who better to teach skills within academia than those who have them?

Over the past few months, the University of Victoria’s Biomedical Engineering program launched a new course taught by StarFish Medical and Stryker employees: BME 401C – Human Factors and Usability Engineering for Medical Devices. The course format consisted of industry employees giving lectures with firsthand experience, demonstrations, and insight into engineering problems faced within the medical devices industry.

A site tour reinforced the importance of practical design skills and inter-departmental teamwork with a purpose-designed facility. The final lecture tied everything together by looking at the big picture in medical device design, then relating the detailed design and development process to making effective and economical medical devices.

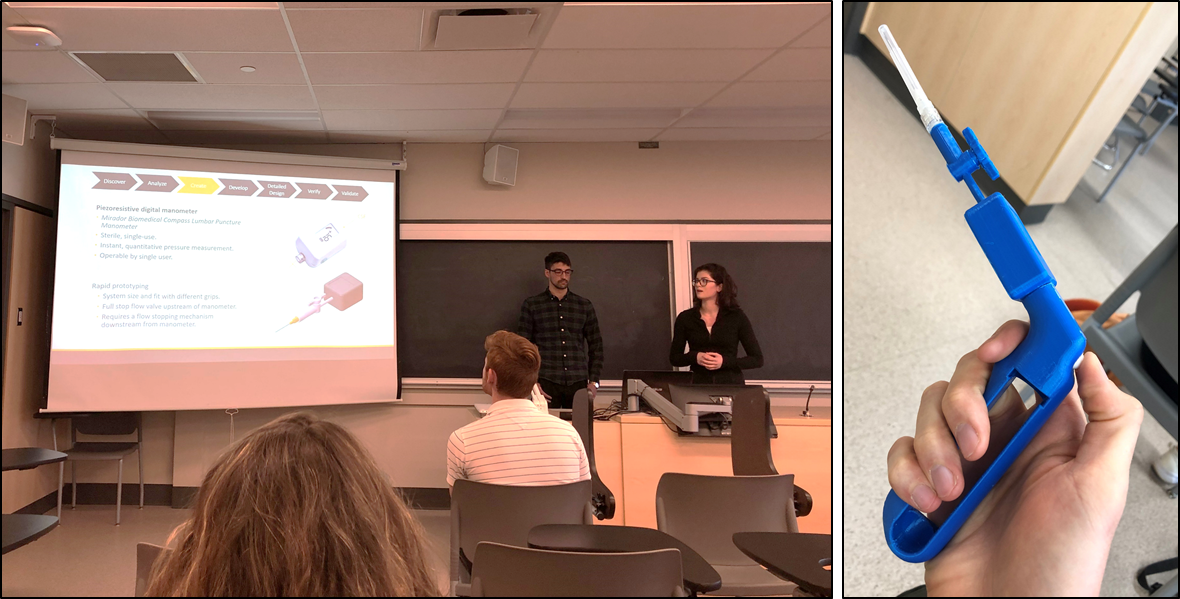

Students put their new skills to practice by designing or critiquing a new or previously existing medical device, respectively. They presented projects with major considerations in risk management and device regulation, formative and summative testing plans, and colour and empathy design.

Top Three Takeaway

After speaking with students, there was a consensus on the top three takeaways from the course:

1. Product development is a diverse, multidisciplinary process

This is something that is not immediately obvious to students after going through their academic programs. Product development requires work and influence from many different departments to go from an idea to a marketable product. It is not a process conducted by one small team of engineers.

2. User input guides device design

A device can have many incredible features with the latest technology and impressive specifications but, if the end user can’t use the device effectively, none of that matters. It is important to involve the user in the design and development process from the very start.

3. Regulations, quality assurance, and risk management is a huge part of the process

Exposure to this aspect of engineering was informative and useful to students. Going deeper into a field which usually only gets a mention in other university upper-level courses sparked interest in students and showed a potential career path.

Overall, the course was well received by students. A survey of some of the students revealed that they learned a lot about the engineering and design process that is not taught in fundamental university coursework. This gave them major insights into company organization and operations. Exposure to fields such as risk management and regulatory affairs was viewed as being extremely valuable and in some cases eye-opening regarding their potential career paths.

Students found learning from several different lecturers to be engaging. Being taught from industry professionals offered a practical outlook that might not be offered from academic professionals. More importantly, industry professionals were enthusiastic about their work and taught using relevant case studies. This translates into an effective teaching experience that sparks interest and drives informal conversation throughout the lectures.

When asked if they thought the course would help them find a job, students unanimously said yes. Lucas Karperien, a graduate student in the course, stated “design is not just the circuits and gears, it’s important to consider the users and the regulations associated.” Others found that the information “good to know for the interview process” and viewed the course style as an opportunity to network and ask informal questions to industry professionals about their work.

No university course is without some critique and suggested improvements. For example, students found that having different lecturers can contribute to some repetitiveness from lecture to lecture. With redundancy removed, there is more time to teach more information and students are happy to learn as much as possible.

Catherine Murphy, an undergraduate Biomedical Engineering student, specifically requested more exploration of the “clinical biomedical engineering” experience and more case studies where post market surveying has an impact on the design of devices. The most common suggestion was to have the project be defined at the beginning of the course and to apply the skills they are taught to their projects right after learning them. This would provide a more hands-on experience and allow for more in-depth evaluation of their medical devices.

Industry involvement can help bridge the medtech skills gap

Industry professionals know best which skills graduates may be missing. Getting involved directly has the benefit of communicating this to students. Additionally, companies often do a lot of recruitment at their nearest universities. By influencing the curriculum, they can improve the local talent pool and connect their organization leaders with top students.

Having industry experts teach a for-credit course at the University of Victoria has proven successful in translating industry knowledge to students. Dr. Stephanie Willerth, the Director of Biomedical Engineering at the University of Victoria, expresses that “BME 401C was a great example of how academia and industry can collaborate to provide unique training opportunities that reflect the breadth and depth of biomedical engineering.” The students like it, and companies and academia stand to benefit from it.

[1] Universities can’t solve our skills gap problem, because they caused it | TechCrunch.

Brent Godau is a mechanical engineering graduate student at the University of Victoria. He researches biomaterials applications in tissue engineering and advanced drug delivery under the supervision of Dr. Mohsen Akbari.

Images: StarFish Medical