Diagnostics

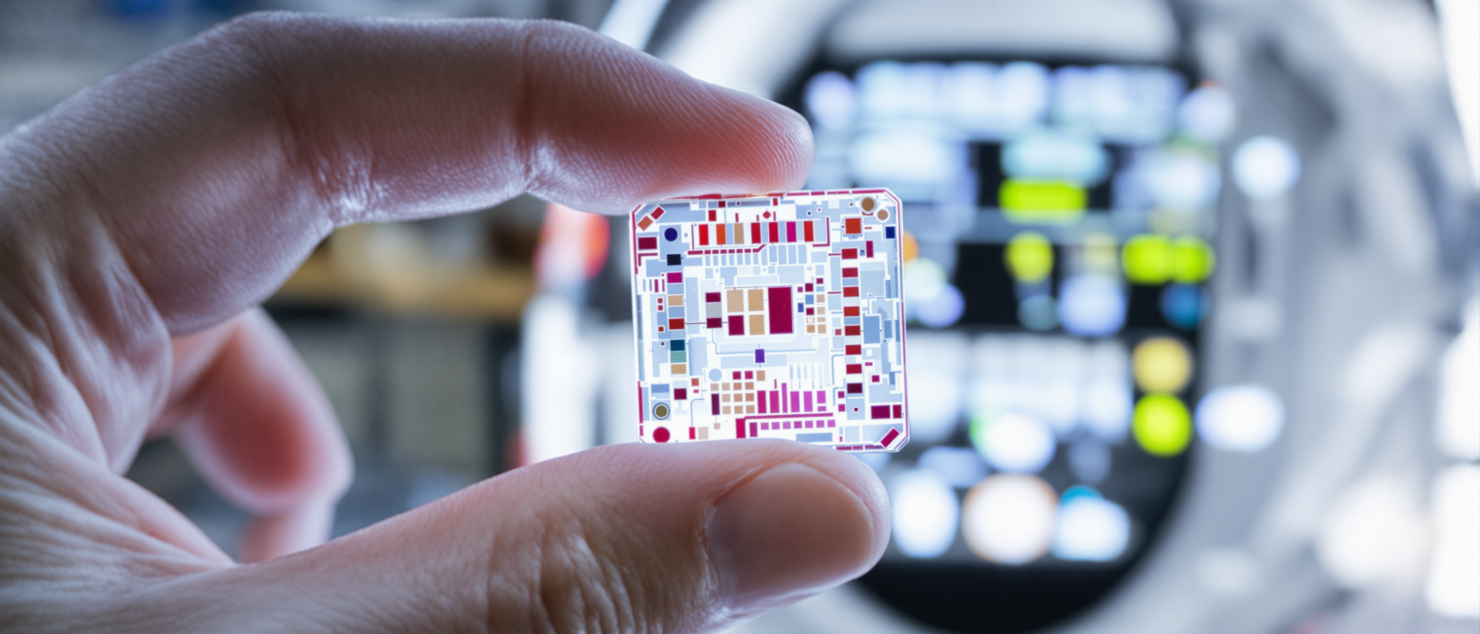

Complex diagnostic equipment, instruments, and bespoke remote diagnostic devices and wearables.

Diagnostics Innovation for Modern Healthcare

Diagnostic devices are getting smaller, smarter, more user-friendly, and more powerful. And by better integrating diagnostic data into clinical practice, diagnostics now play a more crucial role in modern medicine than ever before.

But designing and launching a diagnostic device that actually moves the needle—clinically, commercially, and operationally—is another matter entirely. From precision sensing to secure connectivity, every element must perform under pressure. There’s no room for technical debt, integration failure, or slow decision-making. At StarFish Medical, we partner with leaders across the diagnostic spectrum to build breakthrough devices that hold up in the real world—not just in theory.

Designing Diagnostics That Matter — When Precision and Performance Are Non-Negotiable

In diagnostics, performance is non-negotiable. Devices must generate reliable, actionable data—seamlessly integrated into clinical workflows.

A single misstep in design or integration can ripple through the system—delaying trials, jeopardizing approvals, and eroding clinical trust.

We take a systems-level, clinically informed approach to every project. Our multidisciplinary teams—including PhD scientists, engineers, and usability experts—collaborate to ensure your device delivers precision, consistency, and clinical value.

Building Advanced Technologies into Clinically Viable Products

Today’s diagnostic devices often push technical boundaries—novel sensors, advanced optics, AI-driven analysis, cloud-connected platforms. But innovation alone is not enough: these technologies must translate into products that meet clinical needs, regulatory requirements, and manufacturing realities.

When technologies aren’t grounded in execution, innovation becomes risk—not value.

We excel at bridging this gap. Our expertise spans ultrasound systems, implantable diagnostics, ingestibles, wearable sensors, and beyond. We help you transform innovative concepts into market-ready, clinically impactful products—with a focus on risk management, usability, and long-term reliability.

Transforming Data Into Actionable Clinical Insight

The true value of diagnostic devices lies in how data informs clinical decisions. Yet many promising products falter due to poor data integration, cybersecurity vulnerabilities, or unclear clinical pathways.

When insights fail to reach the right user, at the right time, they stop being insights.

StarFish addresses this from the outset. Our software, data science, and cybersecurity teams ensure that diagnostic data is captured, processed, and delivered in secure, interoperable, and clinically useful ways. Whether cloud-enabled, AI-augmented, or integrated with healthcare IT systems, we help you create solutions that turn data into actionable insights—improving outcomes for patients and providers alike.

Program Execution Designed for Regulatory, Clinical, and Commercial Success

Bringing a diagnostic device to market demands more than technical excellence—it requires strategic program execution aligned with your business, clinical, and regulatory milestones.

The most advanced systems stall without clear planning, agile adjustment, and full visibility.

Our integrated approach combines agile program management with rigorous quality and regulatory expertise. We ensure alignment across stakeholders, manage risks proactively, and maintain full visibility from design through manufacturing transfer. Whether preparing for clinical trials, FDA or CE submissions, or commercial scaling, we help keep your program on track and positioned for success.

The StarFish Advantage

Trusted partner for diagnostic device development—from early feasibility to global scale.

Translating Science Into Product

We work at the intersection of physiology, engineering, and data—turning complex diagnostic insight into actionable clinical tools.

You don’t need a translator. You need a team that speaks all three.

Built for Regulatory, Clinical, and Commercial Realities

Our process is informed by clinical risk, usability, and quality systems—designed to meet the demands of regulators, payers, and providers.

You stay aligned, audit-ready, and launch-capable.

Usability and Human Factors from Day One

We prioritize real-world users in real clinical environments—designing interfaces, workflows, and feedback systems that improve outcomes.

Because if it’s hard to use, it’s hard to adopt.

Agile Execution with Embedded Quality

Our teams combine agile program management with a proven ISO 13485 quality system—driving speed without compromising rigor.

Innovation moves fast. Your quality system should, too.

Precision Engineering for Complex Systems

We build diagnostic platforms that integrate sensing, optics, connectivity, and data analysis—engineered to perform in the real world, not just in theory.

No guesswork. No patchwork. Just reliable clinical performance.

Manufacturing-Ready by Design

We design for manufacturability from the outset, ensuring a clean handoff to your CM or ours—no scrambling, no rework, no surprises.

From clinical builds to commercial ramp-up—without reinvention.

Selected Diagnostic Innovations

Explore Our Services

Ready to explore how we can partner together?

TL;DR

- StarFish Medical helps MedTech teams bring sophisticated diagnostic devices to market with confidence.

- Our expertise spans imaging, biosensors, AI, optics, and connected diagnostics.

- We thrive on solving problems with no off-the-shelf solution—and translating bold ideas into reliable products.

- We deliver both innovation and execution—through clinical validation, regulatory strategy, and design-for-manufacturing.

- Our partnerships are built on trust, precision, and shared commitment to improving patient outcomes.

Related Resources

Electrocardiography (ECG) remains the gold standard for non-invasive cardiac assessment, providing a vital window into the heart’s electrical health. By recording electrical impulses through surface electrodes, clinicians can identify life-critical conditions such as arrhythmias, myocardial infarctions, and conduction abnormalities.

Wearable medical and wellness devices are increasingly commonplace in the healthcare field. For example, devices such as smartwatches incorporate sensors to provide continuous health tracking data to their users.

Nick and Nigel explore how much bacteria can exist on devices and why it matters. They explain that bacteria are everywhere.