5 tips for a productive EMC lab visit

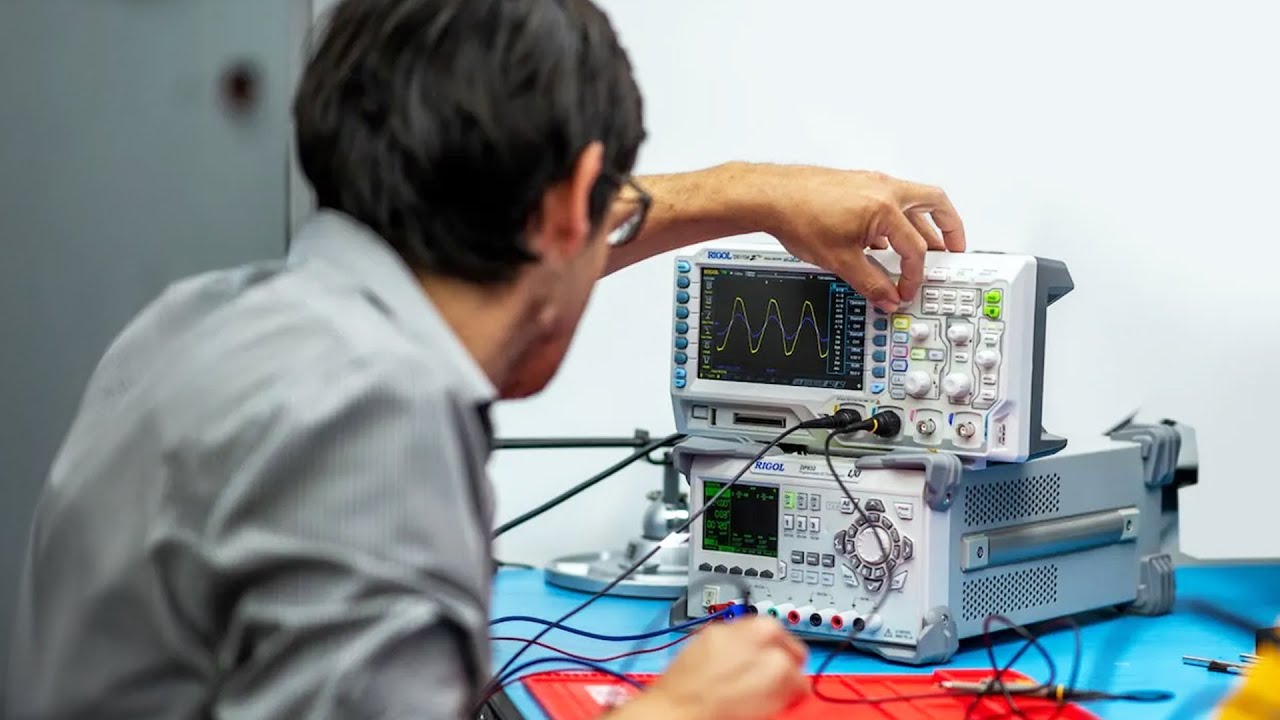

EMC (Electromagnetic compatibility) compliance is an essential requirement for all electronic medical devices. Usually, designers partner with EMC labs (certified testing) facilities in order to assess device compliance. In this blog members of the StarFish Electrical Engineering team share tips for a productive and successful assessment during your EMC lab visit.

EMC

EMC refers to the ability of a system to function correctly within its electromagnetic environment. That is, the ability to operate without generating electromagnetic disturbances that could affect other systems. It also includes the ability to operate without being adversely affected by the electromagnetic disturbances (usually generated by other equipment) expected to be present in its operating environment.

The electromagnetic compatibility of medical devices is assessed according to the tests established in the IEC 60601-1-2 standard Medical electrical equipment – Part 1-2: General requirements for basic safety and essential performance – Collateral Standard: Electromagnetic disturbances – Requirements and tests.

So, what gets tested at the EMC lab?

EMC tests can be broadly classified into two categories: Emissions and Susceptibility.

In the first category radiated emissions are measured by placing an operating UUT (unit under test) in an anechoic chamber (a room that simulates a ‘free space’ condition) and measuring its emission characteristics using a variety of calibrated equipment (antennas, spectrum analyzers, etc.). Conducted emissions (emissions that propagate out the UUT through its power cables) are measured with a piece of equipment known as LISN (Line Impedance Stabilization Network) connected to a spectrum analyzer.

The tests in susceptibility are aimed at establishing whether the UUT can operate correctly when under prescribed electromagnetic disturbances. This includes radiated disturbances, transient voltages, and ESD (electrostatic discharge) testing.

Here are a series of tips that will help you get the most out of your visit to the EMC lab.

Establish a test plan based on risk assessment

The latest (4th) edition of the IEC 60601-1-2 collateral mandates that certain information be included in the Risk Management File. This includes:

- Specific susceptibility pass/fail criteria for safety and performance in relation to EMC.

- Acceptable degradations that do not result in unacceptable risk

- Documentation and justification for increased or decreased testing levels

- Justification of the environment category chosen for the device

- Documentation on how the device is going to be tested to show compliance

This has important implications for EMC testing as all of the above shall be reflected in the EMC test plan to be executed at the lab.

Know in advance of your visit the possible ways your device can fail under susceptibility testing conditions, the severity of each failure mode, and the ways to detect the occurrence of the failures.

Get familiar with the emissions signature of your device

Knowing what to expect at the lab is invaluable. At a minimum you should do a ‘pen and paper’ analysis of your system. Write down the frequencies of the spectral peaks that you would expect to see in each sub-system (typically clocks, oscillators, DC-DC switchers, etc.).

A much more effective approach is to open up your device and ‘sniff’ it. If you can’t afford near-field probes, check out the ones described in Bjarne Hansen’s blog. Note and document frequencies that are high peaks. Look for telltale signs of emissions issues like the same frequencies being seen in many different places (like in cables, different boards, and other sub-components).

Knowing this information in advance will prove invaluable at the lab. If you see a non-compliant peak during the test you will likely know where it is coming from and where to begin your mitigation efforts.

Prepare a tools and accessories kit

When in the lab you will want to have all the tools needed to completely strip down your device: Allen keys, wrenches, screw drivers, etc.

Consider bringing spare cables of different lengths. Bear in mind that you may need to add ferrites to the cable. So make sure you bring cables that are long enough and are well shielded. If you are bringing a laptop that connects to the device, bring sufficiently long cables. Otherwise your laptop will become part of the UUT.

Bring a set of ferrite clamps and copper tape to seal leaky gaps and for general shielding.

Make sure you know the part numbers of all the accessories you are bringing as they may end up in the final spin of your product.

It is not uncommon to tweak your design in the EMC lab. Most facilities provide parts kits and a work bench where you can swap an SMD ferrite should you need to. It is a good idea to contact the lab ahead of time and ask what kind of facilities are available for this kind of ad hoc re-work.

And while on your EMC lab visit…

Be methodical and take good notes

Change one thing at a time and take good notes. Photograph everything (especially the spectrum analyzer screen!). Identify your photographs with a number that you can refer to in your notes. For example, picture #4: We replaced L1 ferrite with part number XYZ.

If you think the last change fixed something, confirm your assumption by undoing the change.

When you do identify a problem frequency start from the source and work your way out

First address the problem emission at the source, then with shielding, filtering (ferrite) at the bulkhead or at the subcomponents. If you can’t, then you have to deal with the problem emission at the system level.

In summary

Invest the time to prepare properly before going to the lab. Do not just show up at the test house and assume you are going to learn and fix everything in one visit. The more you know beforehand about your device and how you are going to test it, the more productive your EMC lab visit will be.

Astero StarFish is the attributed author of StarFish Medical team blogs. This blog includes insights from EE team members Kris Dolberg, Martin Kellinghusen, Christian McMechan, Kenneth MacCallum, and Diego Sorrentino. The blog was edited by Diego Sorrentino. We value teamwork and collaborate on all of our medical device development projects.

Image ID 132233949 © Ryzhov Sergey | Dreamstime.com