Canary Medical: From Concept to Smart Implant Prototype

Reimagining Fracture Healing with Embedded Sensing

Headquartered in British Columbia, Canary Medical is a medical data company developing implantable devices that generate and transmit real-time clinical insight. Their goal is to improve patient outcomes by transforming traditionally passive implants into active sources of health data.

One of their early development initiatives focused on a smart orthopedic screw. The device was designed to track bone healing from inside the body and reduce the need for repeated imaging. It was an ambitious start that aimed to prove embedded sensing could deliver clinically meaningful information from within a complex anatomical environment.

Bringing that device to life required a development partner with the expertise to engineer and evaluate a novel implantable sensing system. That’s why they turned to StarFish Medical.

“StarFish helped us prove it was possible to monitor healing from inside the body. That early work played a key role in shaping our approach to smart implants.“

— Bill Hunter, President and CEO, Canary Medical

Making Healing Measurable

The challenge was as technical as it was visionary: build a fully implantable device that could track biological healing processes without any external imaging. Together, the teams landed on Electrical Impedance Spectroscopy (EIS), a sensing method capable of characterizing tissue conductivity to reflect healing status.

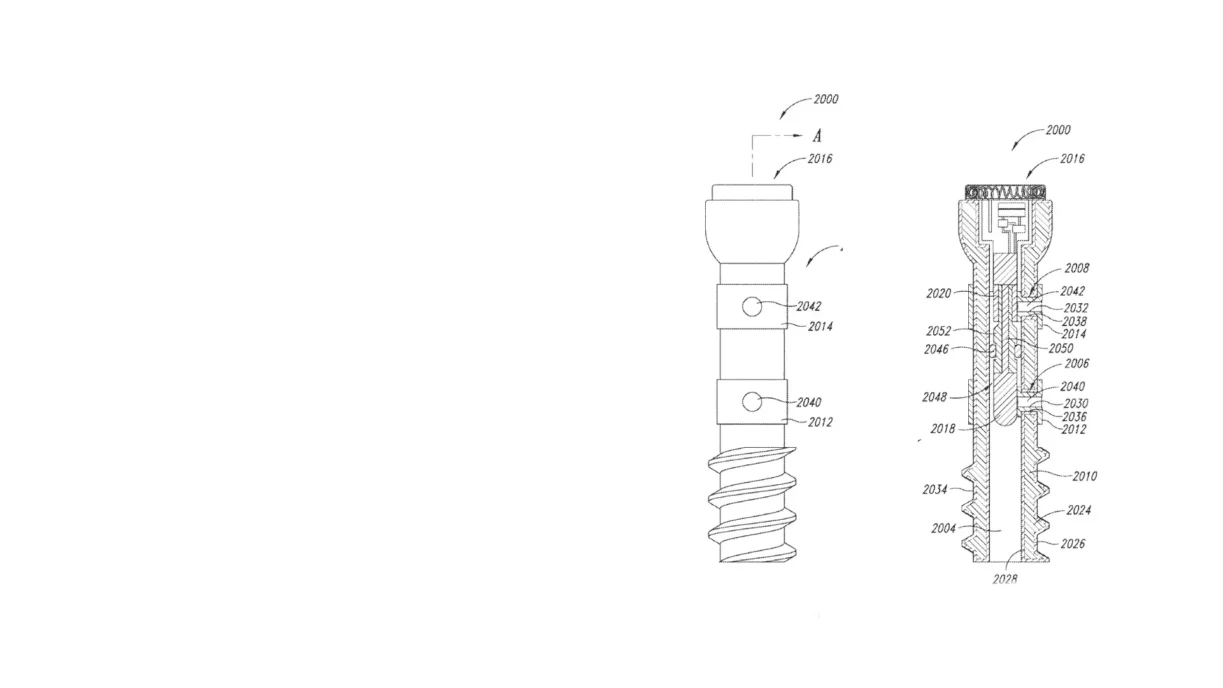

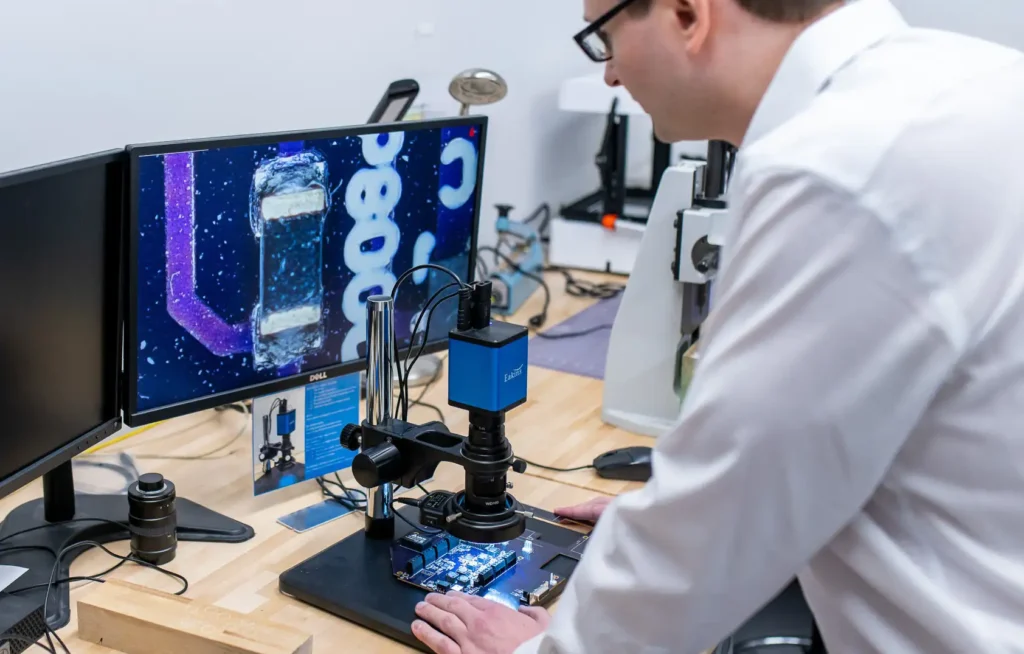

StarFish led the development of a custom sensing strategy and prototyped a system that could withstand the demands of long-term implantation. This included developing the sensing architecture and characterizing early power and form factor considerations for future implantable devices.

To ensure the approach was credible and repeatable, StarFish also replicated published studies in EIS-based tissue monitoring and created a robust bench model to assess fracture healing progression. The engineering work contributed to early intellectual property development, including preliminary patent activity. These efforts established more than technical feasibility; they laid the groundwork for a new generation of intelligent implants.

A Foundation for a New Class of Devices

By the end of the engagement, Canary Medical had more than a concept. Together, the teams had proven the feasibility of using Electrical Impedance Spectroscopy to monitor bone healing from within the body. The work helped establish a technical foundation that expanded Canary’s ongoing development of additional smart implantable devices, including new sensing systems now being explored for orthopedic and spinal applications. The success of this first smart screw opened the door to broader orthopedic applications, giving clinicians a way to track healing from within the body with greater accuracy and reduced reliance on imaging.

Why It Matters

The ability to monitor biological healing from inside the body isn’t just a technical milestone. It’s a paradigm shift. For patients, it means fewer appointments and lower radiation exposure. For clinicians, it means better data and earlier intervention. And for innovators like Canary Medical, it means a credible, scalable platform to build the next generation of intelligent implants.

With StarFish Medical’s support, Canary turned an ambitious idea into a functional device, one that helped define their approach to embedded diagnostics.

Today, Canary Medical is continuing to advance its portfolio of data-generating orthopedic implants and smart sensor platforms. Their work is expanding into new applications, building on the foundational technology validated through this early collaboration. The smart screw prototype helped establish not just technical feasibility, but a strategic vision for how embedded diagnostics can change the future of care.