Toronto – StarFish Medical

Medical Device Design & Engineering – Toronto

Full-service product development for innovative MedTech companies

Complete medical device design, engineering, and manufacturing support from the heart of Canada’s largest life sciences hub.

Housed in the historic Benjamin Moore building in the Junction, our facility brings together cross-functional teams dedicated to transforming complex ideas into manufacturable, regulatory-ready medical technologies.

Expert Medical Device Development in Toronto

Our Toronto-based team of engineers, designers, and commercialization specialists supports every stage of the medical device lifecycle:

Medical Device Design & Systems Engineering

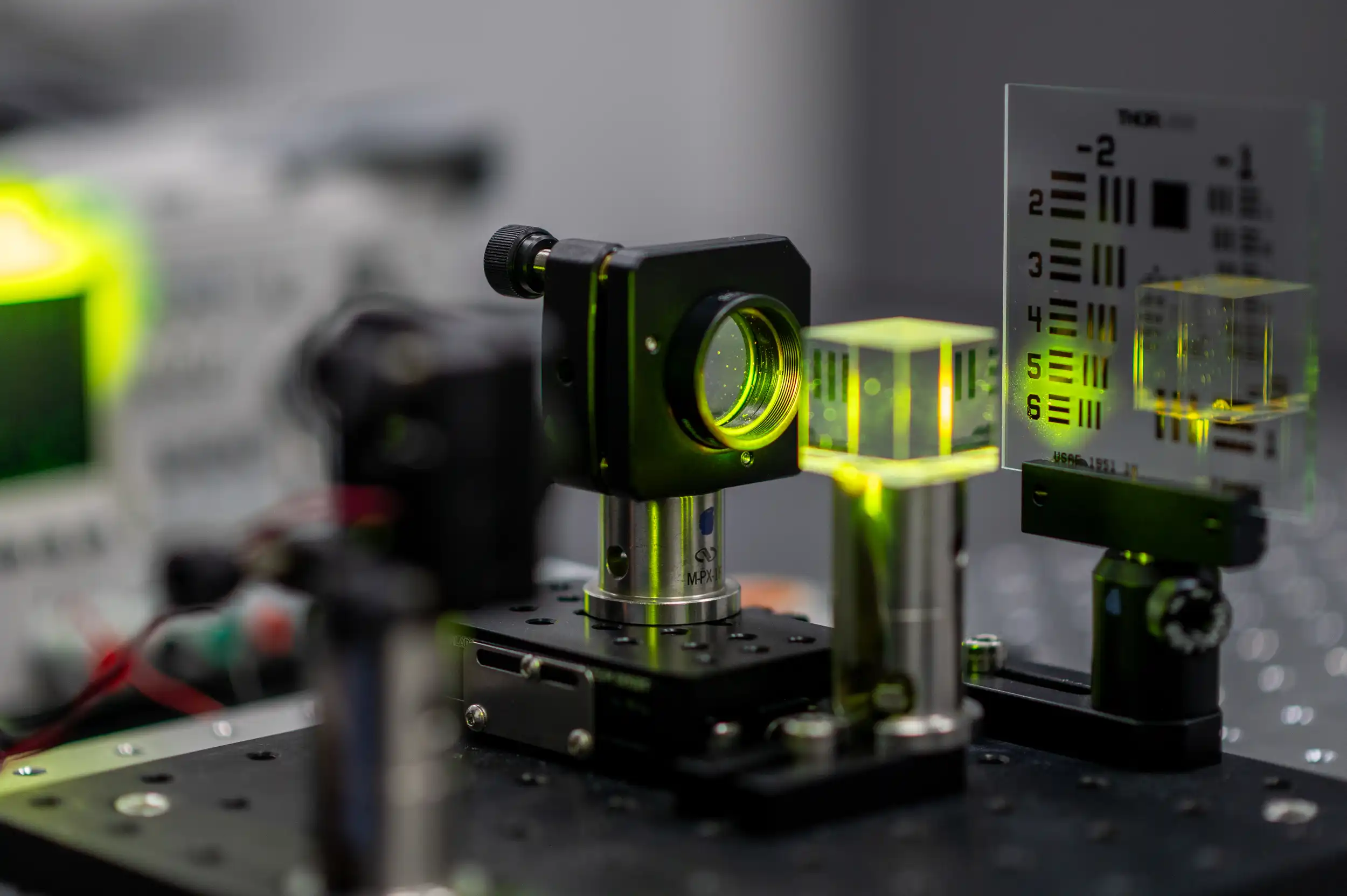

We integrate mechanical, electrical, firmware, software, and optical systems into unified device architectures that balance technical feasibility, regulatory requirements, and business goals.

Human Factors Engineering & Industrial Design

Our usability experts ensure medical devices are intuitive, safe, and compliant with global standards through rigorous human factors research and user-centered design.

Design for Manufacturing (DFM)

Our team identifies risks early and develops robust processes that enable cost-effective, scalable manufacturing without sacrificing performance or compliance.

Regulatory Strategy & Quality Systems

We support FDA, Health Canada, EU MDR, and other global submissions with regulatory strategies tailored to each device class and clinical application.

Medical Device Manufacturing & Transfer to Production

We guide clients through pilot builds, documentation packages, verification and validation (V&V), and smooth handoffs to in-house or contract manufacturers.

Commercialization Support

StarFish Medical helps MedTech companies bridge the gap between product development and commercial success, supporting business planning, IP strategy, and fundraising preparation.

Specialized Sectors We Serve

Our Toronto office contributes to projects across a broad spectrum of clinical and technological domains, including:

- Digital health & wearables

- Diagnostics & imaging

- Therapeutic devices

- Surgical & acute care technologies

- Ophthalmology, cardiology, and orthopedics

Anchored in Toronto’s Life Sciences Ecosystem

We actively collaborate with leading organizations in the region, including:

- MaRS Discovery District

- OBIO (Ontario Bioscience Innovation Organization)

Toronto as a Medtech Innovation Hub

Toronto is home to one of North America’s most active medical technology ecosystems. Our team is deeply embedded in this landscape, offering clients access to a network of clinical collaborators, pilot production partners, and regulatory advisors.

Frequently Asked Questions

What types of medical devices do you develop in Toronto?

We support Class I–III systems, wearables, diagnostics, therapeutic tools, and surgical platforms.

Do you offer medical device manufacturing in Toronto?

Yes — including pilot builds, documentation, and design transfer to CMOs.

Can you help with FDA and Health Canada submissions?

Yes — we provide fully integrated regulatory support for Canadian and U.S. markets.

What sets your Toronto medtech team apart?

Multidisciplinary expertise, ISO 13485-certified processes, and strong local partnerships.

Start Your MedTech Journey in Toronto

Looking for a strategic partner in medical device design, development, or manufacturing?

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.