As a mechanical designer I am often faced with a decision: Should I analyze this mechanism or system? The obvious answer is yes; however, the reality is that there are competing factors that muddy the waters. Competing factors include: Aggressive schedules, cost constraints and resource constraints. The decision to forego an analysis is complex, simple systems or designs that borrow heavily from tried and true designs can often be developed with confidence in the absence of analysis.

The grey area is often the medium complexity semi-unique design where the designer is rushing to make a deadline or is constrained by cost or resources. Analyses can run the gamut from hand calculation to full 3D dynamic non-linear simulation.

The effort to realize an analysis is itself highly non-linear and complex 3D simulations can require weeks of effort and monopolization of the software resource. In addition, any errors in the setup of the problem can be devastating as the error may not be evident until the results are available.

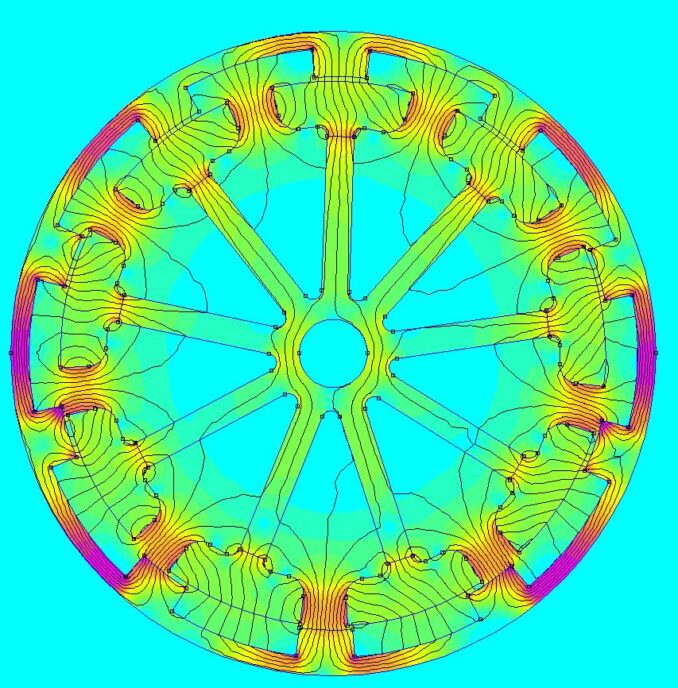

An antidote to this analysis-resource tug of war can be 2D simulation. Many problems are two dimensional or can be simplified to yield acceptable results with a two dimensional treatment. Typical two dimensional simplifications are planar symmetry (i.e., a section cut through a body or system with planar symmetry) and axis symmetric problems (i.e., a slice from a revolved structure demonstrating polar symmetry).

Recognizing a problem is two dimensional or that it can be approximated by a two dimensional simplification can reduce problem setup time significantly and reduce computation time by several orders of magnitude.

Furthermore, the ability to model complex systems involving contact of disparate bodies and large deformation using 3D techniques often necessitated rudimentary meshes due to memory constraints rendering the analysis suspect.

A classic example of the application of a 2D analysis is the design of a plastic snap hook. A section through the snap hook can be rapidly meshed, analyzed and iterated. A hook that snaps into a non-rigid recess is even more challenging and computationally intensive with 3D techniques.

A 2D analysis can handle this very quickly and gives the engineer an opportunity to iterate several times in a time frame that makes skipping the analysis difficult to justify. Problems ranging from electrostatics and magnetics to fluids and structural analysis can be rapidly analyzed using 2D techniques.

Should I analyze this mechanism or system is not a simple question; however, if a 2D simplification can be used the answer is, “How can I afford not to?”

Boyd Allin holds a Bachelor’s degree in Mechanical Engineering from Queen’s University in Kingston, Ontario and a Master’s degree in Mechanical Engineering from the University of British Columbia. Please visit our Medical Device Product Development page for more information.

Image: StarFish Medical