Bio Break: Clinical Trials for Medical Devices vs. Pharmaceuticals

In this episode of Bio Break, Joris van der Heijden and Nick Allan break down the key differences and similarities between clinical trials for medical devices and pharmaceutical products. As the conversation unfolds, they provide valuable insights into the distinct processes and challenges associated with these two types of trials, including the complexities of combination devices that bridge both worlds.

Nick begins by explaining the unique goals of clinical trials for medical devices. These trials focus on proving safety, efficacy, and the performance claims of the device in real-world settings. For example, diagnostic devices must demonstrate their ability to detect targets reliably and accurately, whether in a clinical laboratory or at the point of care.

In contrast, Nick outlines the four distinct phases of pharmaceutical clinical trials:

- Phase 1: Conducted with healthy volunteers to evaluate safety and dosage, often involving a small group of participants (around 50 people).

- Phase 2: Tests the drug’s efficacy in the target patient population, expanding the study to hundreds of participants.

- Phase 3: Compares the drug against existing treatments or the standard of care in a much larger population, often with thousands of participants, to prove differentiation and effectiveness.

- Phase 4: Post-market surveillance monitors long-term safety, side effects, and real-world performance after regulatory approval.

Nick highlights how medical device trials share parallels with pharmaceutical trials but often focus on different priorities, such as functional testing, usability, and regulatory claims. The discussion becomes especially intriguing when considering combination products, which integrate medical devices with pharmaceutical components, requiring alignment across both regulatory pathways and clinical trial objectives.

This episode is essential viewing for anyone working in medical device development, pharmaceuticals, or combination products. Gain a clear understanding of the clinical trial landscape and how these processes ensure safety, efficacy, and market readiness for innovative healthcare solutions.

Clinical Trials for Medical Devices vs. Pharmaceuticals

Related Resources

Ariana and Mark examine the complexities of endoscope reprocessing, one of the most difficult tasks in medical device hygiene.

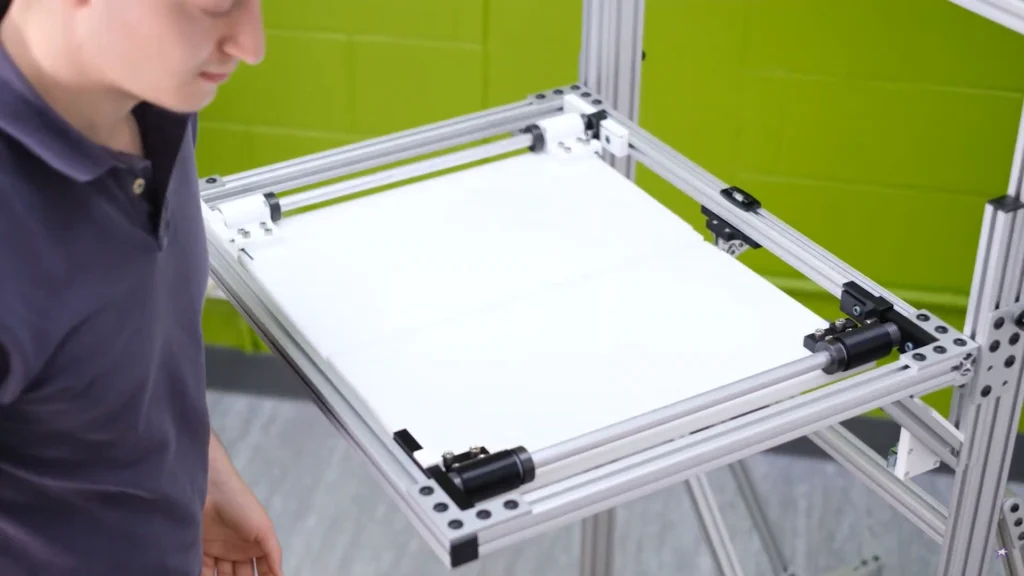

Medical device drop testing helps ensure that products and packaging survive real-world handling. We demonstrate in-house drop testing on an actual device and its packaging using a custom-built drop tester.

Medical device startups/founders and enterprise partners have unique strengths and goals, which are often reflected in the way they work with CDMO (Contract Development and Manufacturing Organizations) partners.

In the highly regulated world of medical device development, ensuring product safety, quality, and compliance is essential. One critical yet often overlooked aspect of this process is test method validation (TMV) in medical device development.