If I was to describe design control for consumer vs medical design in sports terms, medical design would be cricket and consumer design would be ice hockey. That is to say medical devices use a slow, carefully considered and accountable design methodology while consumer goods are bunch of aggressive speedsters shooting the puck around hoping something sticks.

In the consumer design environment, design control is all but unheard of. Of course there are a bunch of standards that need to be adhered to depending on the device and its use: ISO, BS, RoHS, REACH and CE to name but a few. But this is not design control.

Also levels of acceptable performance and quality will differ from one company to another, including within their product range. But this isn’t design control either.

What is design control?

Design control is a set/framework of quality practices and procedures incorporated into the design and development process that ensures safety and efficacy within the design and manufacturing processes.

“Design controls designates the application of a formal methodology to the conduct of product development activities. It is often mandatory (by regulation) to implement such practice when designing and developing products within regulated industries (e.g. medical devices).” (Wikipedia definition)

From a high level, medical device design control encompasses:

- Design and development planning

- Design input including intended use and user needs

- Design output including evaluation of conformance to design input requirements through formative and summative evaluations

- Design review

- Design transfer ensuring that the device design is correctly translated into production specifications

- Design changes

- Design history file (DHF), a demonstration that the design was developed according to the approved design plan and the FDAs 21CFR 820.30.

Design control is important because it gives traceability and accountability to the design process, a critical component in something as hypercritical as medical device design.

Why isn’t design control prevalent in consumer goods?

Due to short product life cycles in the consumer goods industry it’s more about the race to the market and having product on the shelves than whether the device initially does what you say it will do, or not. It is often more important having something tangible in the marketplace first. This can, at times, be costly to the company but it’s a risk they feel is worth taking.

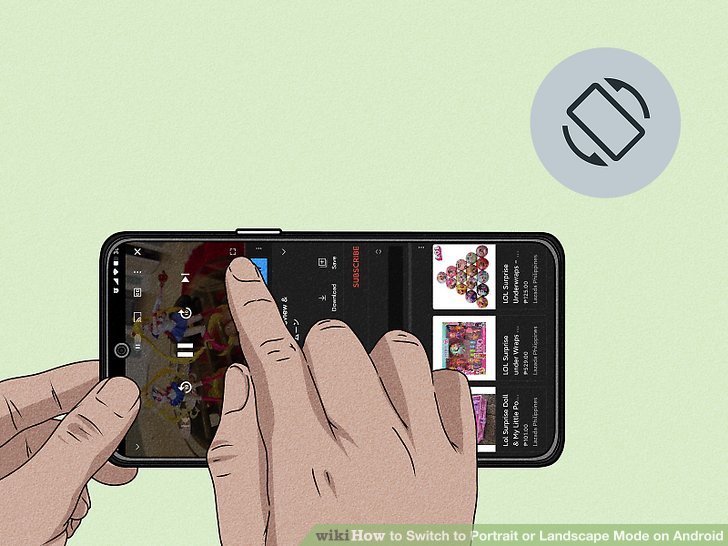

A good example of this is in cell phones. In 2007 Apple brought out the first iPhone. Within a year, HTC (a company relatively unknown internationally) released their spin on the iPhone, the HTC Dream (see image at top of blog). This was a risky move on something as groundbreaking as the iPhone, but understanding the value of being the first android to market they did so none the less. HTC’s revenue for 2016 was a whopping $5.5bn. Clearly being first to market paid off in this case.

Putting something out on the market and hoping for the best does not always pay off, even for the big dogs in the industry. As the race for the “next big thing” grows, the pressure to develop technology that’s better, faster and more powerful is ever increasing. In 2016 Samsung released the Note 7. They had not fully completed the testing and no design control had been performed. A manufacturing defect in the phones’ batteries caused the batteries to generate excessive heat, resulting in fires and costing the smartphone maker at least $5bn to resolve.

Medical, design controls are in place to prevent exactly this. Design controls ensure what you say you are going to do, you do, and you do safely. For example putting out Bluetooth devices in the consumer electronics field is a common occurrence. Sometimes, as I’m sure you can relate, they are a little buggy, sometimes they don’t pair immediately or there is a delay between the devices. No problem, wait a second… or perhaps hit the reconnect button and bingo you’re back up and running.

Why design control is required for medical devices

In the medical device industry buggy connections could be a life or death situation, never mind a catastrophic device failure. In medical design when we say a product will have uninterrupted communications between devices we have to prove that’s exactly what’s happening.

Device failure is not only about a mechanical or technology failure, it’s also about use failure. An example I like is; if you take out a needle and accidently poke yourself with it, that’s not the user’s fault. That’s a use or design failure. Within the design control process, a huge emphasis is placed on human factors and usability engineering. As medical devices are often of critical importance, it is paramount that they are designed in such a way that not only does the design mitigate use errors for normal use, but it also considers the safety and efficacy as they pertain to device misuse. This is a long, precise and methodical process that is, for the most part, unnecessary in consumer goods.

Another reason for a longer design controlled process is that medical device products often stay in the market for many years and, in some cases, even decades. Medical products are required to maintain a DHF (Design History File) for 5 years after the device has finished its last production run and sometimes longer. This is something that would be redundant and extraneous in consumer products that often have a considerably shorter life span.

In essence, design control, as it pertains to regulated industries such as medical and aviation, is superfluous in the consumer goods design. This has its advantages and disadvantages to the regular consumer. The main advantages being quick, cheaper products and the main disadvantages being a lack of accountability, quality and longevity.

Niall Redmond is a former StarFish Medical Industrial Designer. He brings 15 years of cross industry experience and a sense of humor to a wide variety of medical device projects. He is a die hard hockey fan.

Photo credit: Travis Boylls wikiHow Technology Writer