Heart valve simulation offers unprecedented insights into the function, health, and treatment of vital components of the human heart.

This blog explores the heart valve simulation, its significance, and prospects.

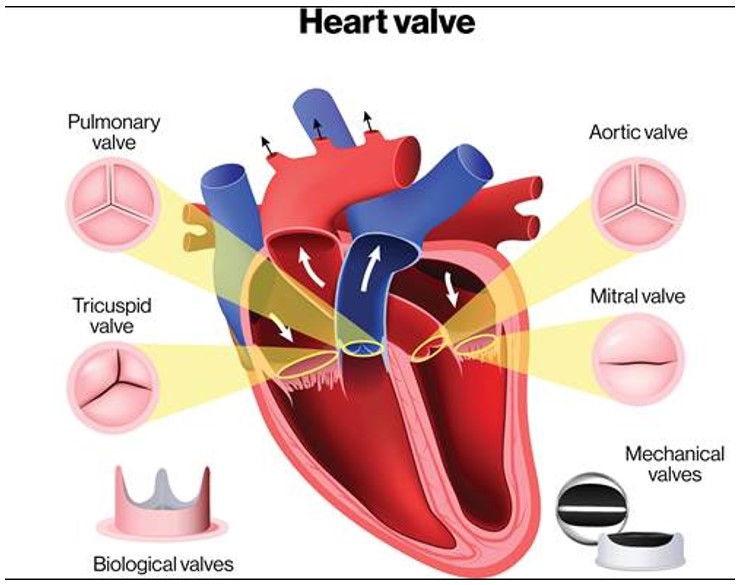

Heart Valves and Simulation

Simulation can be used in many capacities starting from design, to testing heart valve devices in vivo.

Various valvular diseases can affect the valvular function. Depending on the severity and co-morbidities, treatment options can be broadly categorized as:

i) Valve Repair where native valve is repaired to restore its function

OR

ii) Valve Replacement where an external valve is implanted

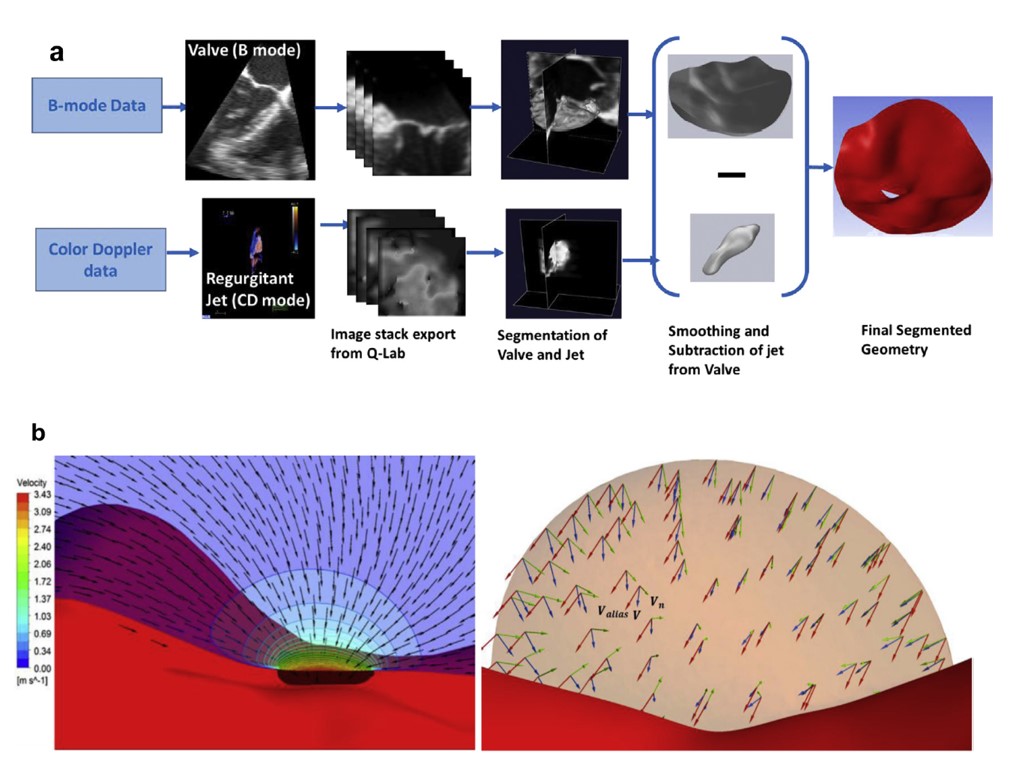

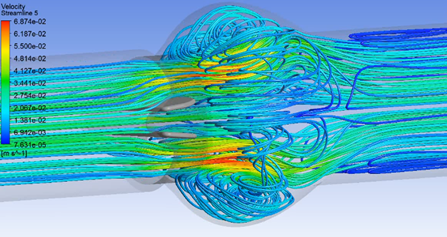

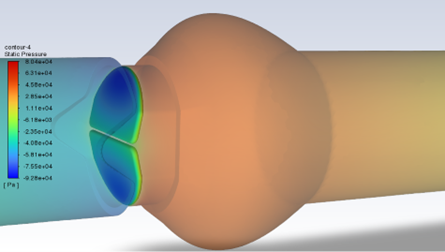

One of the key advantages of simulation is that it computes flow metrics with finer spatial and temporal resolution than possible with any available in vivo imaging technique. It provides the flexibility to analyze and understand minute details enabling strategic decisions based on the overall performance evaluation.

Moreover, simulation can measure parameters that cannot be measured easily in clinics or experimentally. Simulation can provide the thrombogenicity potential quantitively (e.g. an estimate of residence time) and hence, thrombogenicity potential of the blood. It can also provide the stress and strain results on the heart valve with unparalleled resolution. It can predict the strain rate based accumulated damage of the blood inside the heart. This information can be critical in characterising the heart valve performance.

Although simulation can be used in all stages of development, this blog highlights the aspects of simulation relevant to the downstream side of the product development such as performance evaluation and testing.

Role of Simulation in Heart Valve Repair:

Valve repair involves structural modifications to the native valve to restore its function. Simulation can be a powerful tool in providing insights and evaluations for different treatment options and selecting the best option for the patient. This can result in better treatment planning and reduce risk to the patient.

Simulation can assess the effect of potential structural changes to valves. For instance, during repair of a mitral valve, the anterior or posterior leaflet may need to be surgically trimmed to enhance the coaptation of the leaflets and prevent backflow or regurgitation. Simulation can simulate the effect of these structural changes on blood flow velocities, pressures and the amount of backflow inside the heart.

One of the most common surgical interventions is valvuloplasty- the repair of the valve stenosis where the valve becomes narrower, and the heart has to pump harder. A balloon is used to expand the valve annulus to relieve the stenosis. Simulation can assess the effect of enlargement on the heart function and valvular dynamics.

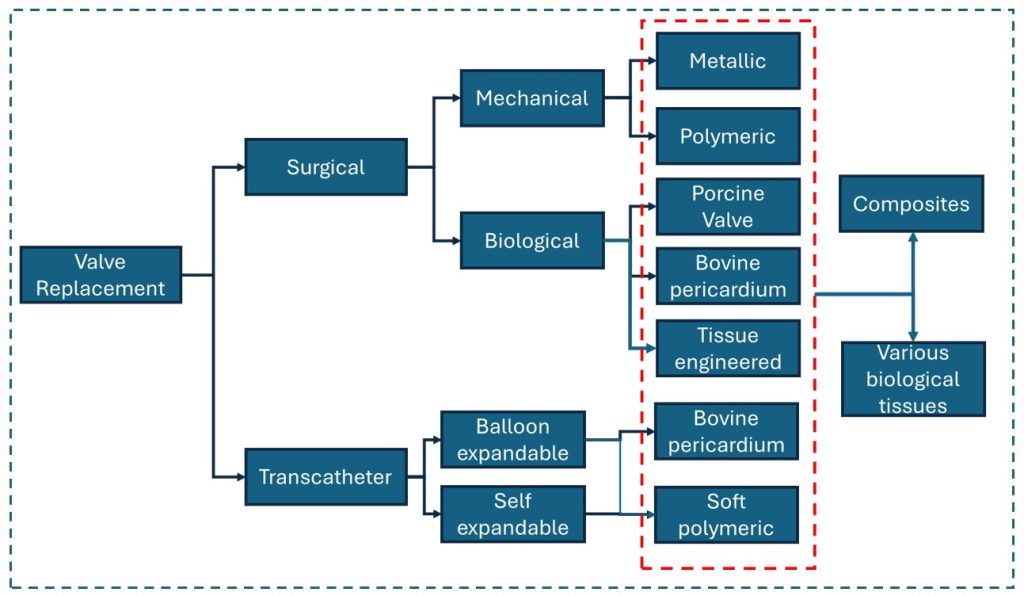

Role of Simulation in Heart Valve Replacement:

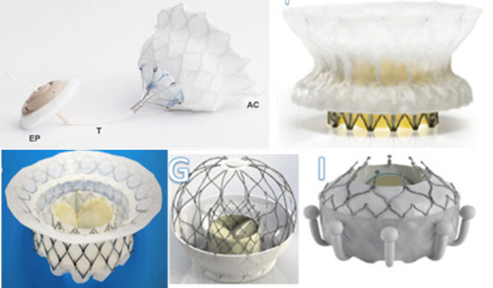

Heart valves can be replaced depending on the indications such as valve insufficiency or stenosis. Valve replacement can be categorized based on implantation method and the valve material as shown in Figure 3. Traditionally, surgical valve replacement (SVR) used to be the only definitive treatment but was deemed unsuitable for patients with comorbidities or higher age. Heart valve replacement has been revolutionized since the development of minimally invasive procedures such as Transcatheter Aortic Valve Replacement (TAVR), Transcatheter Mitral Valve Replacement (TMVR) or Transcatheter Tricuspid Valve Replacement (TTVR)(Fig. 4-5).

The global heart valves market size is projected to reach USD 31.27 billion by 2032, exhibiting a CAGR of 11.8% during the forecast period [3]. Considering the increasing demand for implanted valves, simulation will become increasingly important as an effective tool for valve as well as delivery system derisking. The ability of simulation as a robust and adaptable tool will always keep it abreast with the rising market trends and innovation demands of the industry.

Simulation can assess the safety and efficacy of implanted valves in-vivo. For instance, valve dynamics such as opening and closing behaviour of the implanted valve during TAVI or TMVR can be assessed before implantation. Different valve sizes can be tested to determine which size is best suited to the patient using the characteristic velocity and pressure profiles.

Simulation can be used for hemodynamic assessment of emerging technologies such as Mitraclip and TriClip that are making the boundaries between repair and replacement less rigid- i.e. they can be integrated into transcatheter replacement delivery systems to repair the mitral and tricuspid valves respectively. Other emerging technologies such as testing new materials for polymeric valves or evaluating their in-vivo performance can be one of the next avenues for simulation.

The Future is Here

Simulation technologies are revolutionizing the field of heart valve repair and replacement, offering unprecedented insights and capabilities. Enhancing our understanding of valve mechanics, improving device design, optimizing surgical techniques, and enabling personalized treatments, simulations are paving the way for better cardiovascular care and patient outcomes. As simulation technologies continue to advance, their impact on heart valve research and clinical practice will undoubtedly grow, heralding a new era in cardiovascular medicine.

Muhammad Jamil, PhD, is a Research and Development (R&D) Engineer in the Design and Analysis group at Starfish Medical. As part of the design and development team, he specializes in using Computational Modeling and Simulation in making design decisions and to accelerate the medical device development.

[1] https://www.heartandstroke.ca/heart-disease/conditions/valvular-heart-disease

[2] Jamil et al. Feasibility of Ultrasound-Based Computational Fluid Dynamics as a Mitral Valve Regurgitation Quantification Technique: Comparison with 2-D and 3-D Proximal Isovelocity Surface Area-Based Methods:Ultrasound in Medicine and Biology 2017, 7, 1314-1330.

[3] https://www.fortunebusinessinsights.com/industry-reports/heart-valves-market-101183