Bio Break: How to Ensure Targeted Drug Delivery Hits the Right Spot

In this episode of Bio Break, Nick Allan and Joris van der Heijden tackle the fascinating challenge of targeted drug delivery. When administering drugs to specific areas in the body, how can we be certain they reach the intended target? Nick shares an exciting example involving an intranasal device designed to deliver drugs precisely to the olfactory cleft—an area located between the eyes.

From initial bench modeling with plastic nose prototypes to sophisticated human trials, the episode breaks down the multi-step process used to confirm drug deposition. Learn how techniques like using food coloring on prototypes and delivering radiotracer technetium-99 for imaging helped refine their approach. Nick dives into the advanced use of CT scans and radioactivity mapping, followed by real-world testing with medical-grade methylene blue and ENT scope visualization.

The team showcases how the integration of engineering, human trials, and medical-grade testing leads to reliable results in targeted delivery systems. Discover why these detailed studies are crucial for verifying that drugs reach their destination, ensuring safety and effectiveness.

Whether you’re a medical professional, device developer, or simply intrigued by how cutting-edge drug delivery works, this episode offers insights into the science and technology behind targeted solutions.

Key Topics Covered:

- Real-world examples of ensuring precision drug delivery

- Targeted drug delivery to the olfactory cleft

- Using radiotracers like technetium-99 in imaging trials

- Employing methylene blue for visible deposition tracking

- Challenges and solutions in intranasal device testing

How to Ensure Targeted Drug Delivery Hits the Right Spot

Related Resources

Ariana and Mark examine the complexities of endoscope reprocessing, one of the most difficult tasks in medical device hygiene.

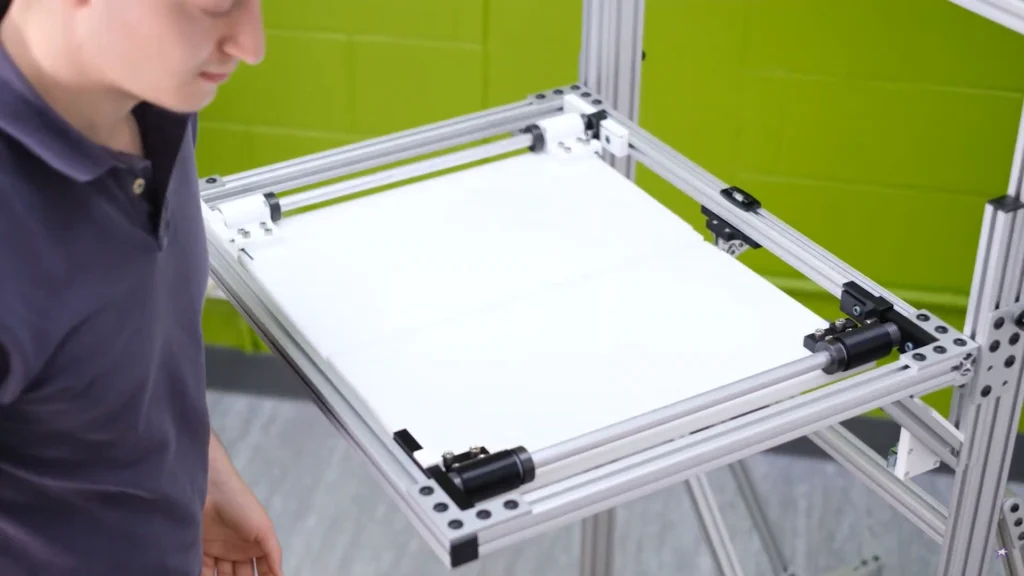

Medical device drop testing helps ensure that products and packaging survive real-world handling. We demonstrate in-house drop testing on an actual device and its packaging using a custom-built drop tester.

Medical device startups/founders and enterprise partners have unique strengths and goals, which are often reflected in the way they work with CDMO (Contract Development and Manufacturing Organizations) partners.

In the highly regulated world of medical device development, ensuring product safety, quality, and compliance is essential. One critical yet often overlooked aspect of this process is test method validation (TMV) in medical device development.