5 Most common simulated biological fluid recipes

Medical devices such as glucose meters, stents or dialysis equipment (to name a few) require intimate contact with biological material. They must either interact with bodily fluids, or function within a biological environment. This blog provides 5 of the most common simulated biological fluid recipes to aide in medical device development.

In order for devices that require intimate contact with biological material to operate as intended, they must be able to withstand the unique conditions that biological fluids impose. Depending on the site of use, the constructed parts must undergo extended exposure to high or low salt concentrations, acidic or basic conditions, a range of degradative enzymes and/or microbial interactions. Simultaneously, the pieces must be void of toxic components, toxic breakdown products, allergenic materials or materials that compromise the target samples.

To aide in the development of such medical devices, the industry employs artificial reagents, or Simulated Fluids (SFs), that act as surrogate test environments. These solutions mimic different biological characteristics. They are inexpensive, well-defined and reproducible reagents in which a device (or its constituent parts) can be tested and optimized. They allow for early stage design choices to be made in construction materials, overall size and shape. Equipment and functionality can be investigated without the high costs of animal trials and exposure risks to infectious agents.

Simulated Fluids can incorporate the key factors that are present in a biological system. These factors may include pH, ion concentration, viscosity, temperature, density, biological activity, enzyme activity, electrical conductivity, or a combination of the above. Different SFs may be optimized to test different parameters. In order to choose the best SF formulation for a particular task, one must understand which parameters the fluid’s ingredients mimic (and, conversely, which parameters they don’t).

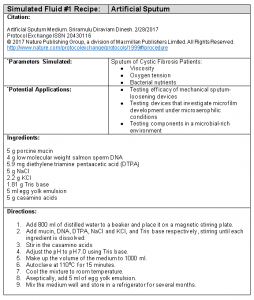

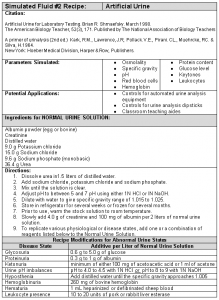

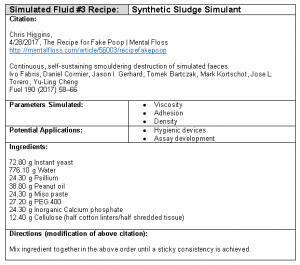

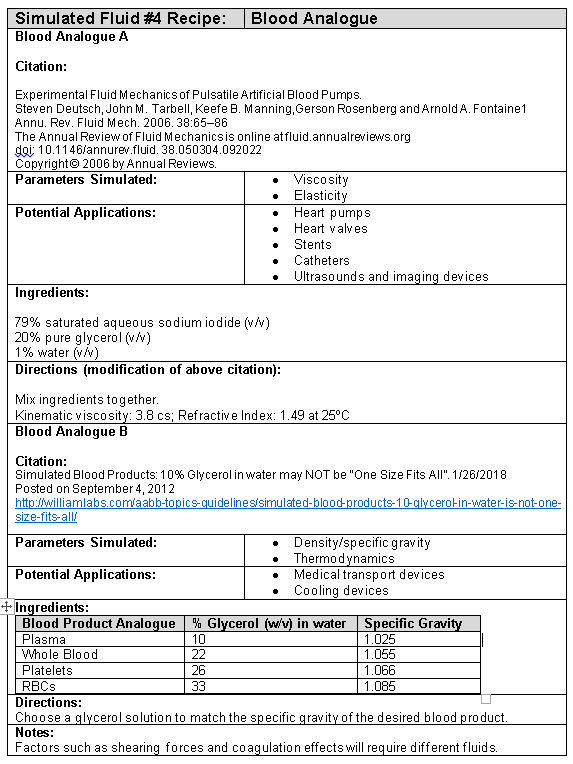

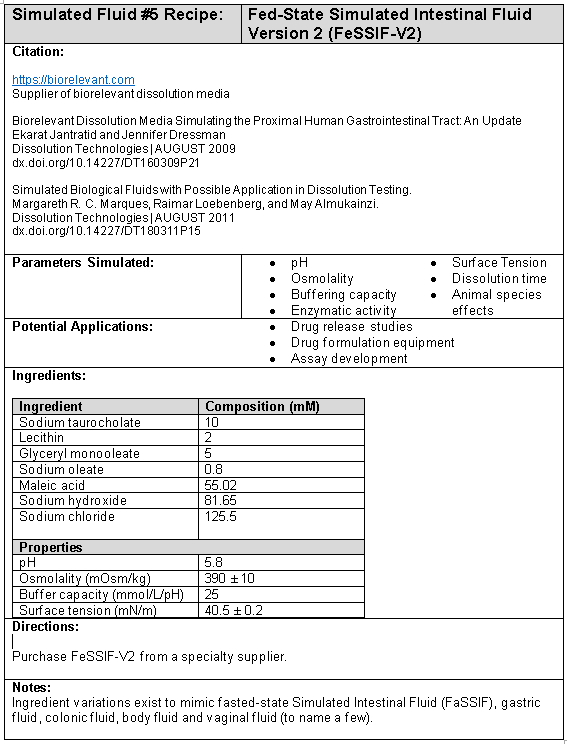

Artificial fluids range in complexity. Often, a number of SFs are employed to assess which parameter is having what effect on the final integrity of a test article. In order to emphasize the diversity and specificity of SFs, recipes for five types of fluid analogue are described below. The goal is to highlight strengths and potential application that the optimal SF can have on developing a quality medical device.

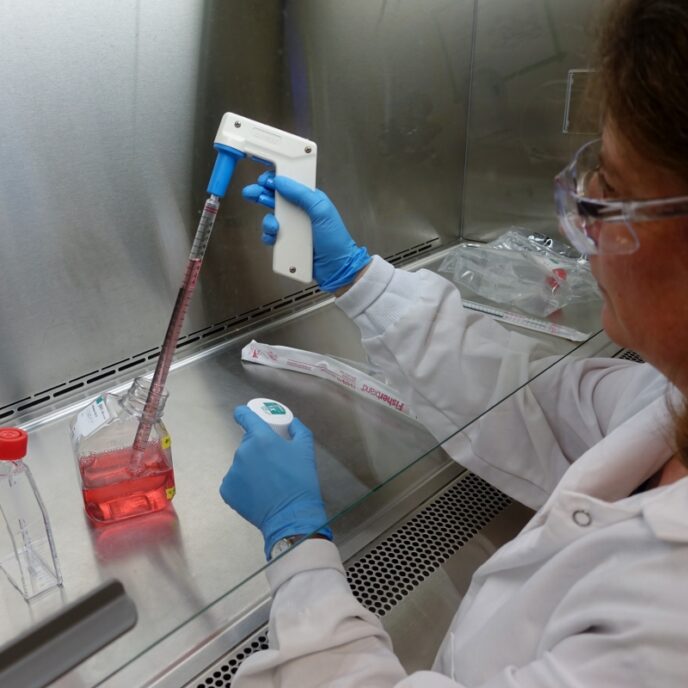

Sue Bantroch is a Biomedical Engineering Technician at StarFish Medical. She works on a variety of biotech medical projects splitting her time fluidly between our main facility and our BSL2 facilities at the University of Victoria.

Title image: StarFish Medical