On-time medical device manufacturing builds are a crucial factor to meeting program and client needs. The type of builds can range from first-off prototypes for preliminary verification studies to clinical studies and first-to-market devices after having received FDA clearance.

Ensuring builds are done in a timely manner requires coordinating across several teams including engineering, manufacturing, and quality. In addition, other resources such as cleanrooms and equipment must all be functional and reserved, along with ensuring all required components and tools are available to meet the build delivery deadlines.

This blog describes how Visual Project Management (VPM) and Manufacturing Production Schedules (MPS) help improve manufacturing performance.

Assess at a Glance

A project manager must be able to give regular status updates on the build progress and assess at a glance if there are any blockers or risks that need to be escalated. These status updates are provided to all stakeholders to give visibility on when builds will be delivered and to advise if there are any concerns that may impact the builds. There are many ways in which to track this information but one invaluable tool that can be utilized is the use of visual project management that allows everyone to visualize the status and the progress of the project.

Manufacturing Production Schedule

A Manufacturing Production Schedule is a great example of a VPM tool that a project manager can use to provide an overview of status updates. The MPS is built collaboratively with all team members’ inputs. When a cross-functional team is involved in the creation of the manufacturing plan, it leads to the establishment of realistic timelines in the schedule and promotes buy-in from the team. When issues do arise, they will also feel empowered to highlight the risks, so the team can then work together to troubleshoot issues and resolve any concerns.

Visible to the Team

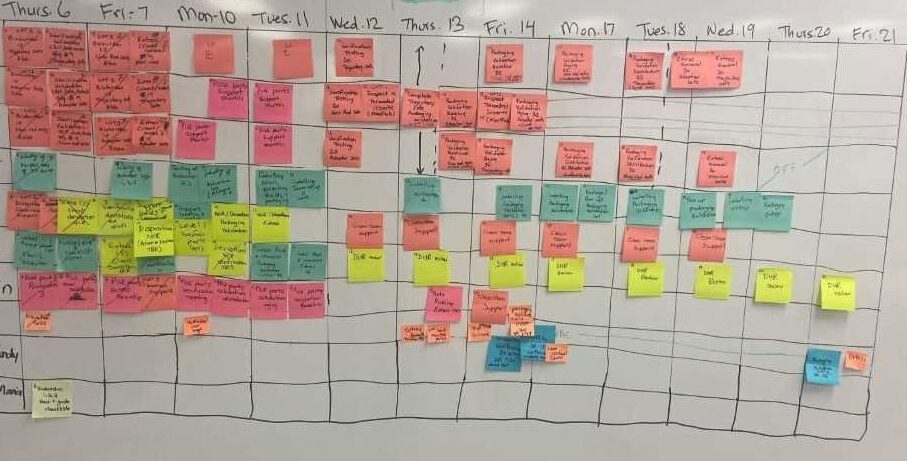

For best use of an MPS, find a location where it will be visible to the team on the manufacturing floor, where it can be reviewed and referenced as needed throughout the day. In a recent project I led, the manufacturing team selected a large portable whiteboard for their MPS. We outlined the build cadence in time increments that provided the needed level of granularity to give visibility into meeting timelines – the closer and more critical the timeline, the smaller the time increment. For this project, the team determined it was best to show a two-week schedule in daily increments. We identified these daily increments across the top of the board in the columns.

Swimlanes

Next, we created a horizontal row or ‘swimlane’ for each team member and outlined the tasks they would be responsible to execute each day. Once these were done, the entire team reviewed the tasks collectively to confirm they made sense and were achievable in the time frame outlined. In addition, the team discussed any dependencies between tasks or inputs that might be needed.

This review helped the team identify gaps in the schedule and allowed them to work together to update the schedule in real time. Post-It Notes are useful in creating the MPS as they allow the movement of tasks and other necessary updates to be done with ease.

Execute the Plan

Once the MPS is created, it is time to execute the plan! To make sure the team is aligned, schedule daily stand-up meetings, conducting them at the MPS board. During the first couple of days in our example project, the team found two stand-up meetings for 30 minutes each at the start and end of the day were most valuable to address the high number of blockers and issues that arose. Eventually the team was able to reduce this down to one daily 15-minute session during a more streamlined execution phase.

Stand-up meetings are an opportunity for team members to align on the progress made and to communicate issues and any support needed. The project manager gains awareness of any blockers and can get needed equipment or set up additional troubleshooting sessions. Additionally, work amongst team members can be reallocated as required and schedule updates are made on the VPM board during the meeting.

Always remember to be flexible and make adjustments as needed! In my example, further breakouts were necessary, so the daily tasks were then further broken down into a morning/afternoon cadence to facilitate alignment with other team members. Once a task is completed, it can be crossed out or removed from the board to ensure the remaining tasks can be tracked for progress.

Summary

The Manufacturing Production Schedule is an invaluable tool used by manufacturing teams to support builds with an aggressive schedule because it allows teams to optimize and reallocate work in a flexible and timely manner.

In my real-life example project, the team used visual project management and manufacturing production schedules to effectively work together and deliver builds on time as per the planned schedule! All the lessons learned from these builds will help the next round go even more efficiently. None of this would have been possible without having an engaged team working together!

Sandy Gill is a Program Manager at StarFish Medical, who previously held management positions at Sciex, a Danaher company, overseeing Sustaining Engineering at a manufacturer of mass spectrometers. Sandy holds an MBA from Wayne State University and a B.S. in Chemical Engineering from McMaster University.

Images: StarFish Medical