Three Considerations for Water Ingress in Medical Devices

Navigating water ingress in medical devices can be tricky, as one of the key requirements for ISO 60601-1 is the protection against ingress. With so much development focused on the functioning of the medical device, ingress protection can be overlooked or left late in the development phase as something that is easily solvable.

There are two clauses, 6.3 and 11.6; the former deals with ingress harmful to the device, with 11.6 focused more on cleaning and usability due to ingress, overflow, and spillage. Medical device enclosures need to be classified according to their requirements with the classification per IEC 60529, or IP rating (ingress protection rating).

In this blog I’ll talk about 3 areas of concern for water ingress in medical devices:

- Cleanability – needlessly high IP requirements can have unintended consequences

- Orientation – understand which way is up

- Heat dissipation – understand your heat dissipation requirements

What are the IP Ratings?

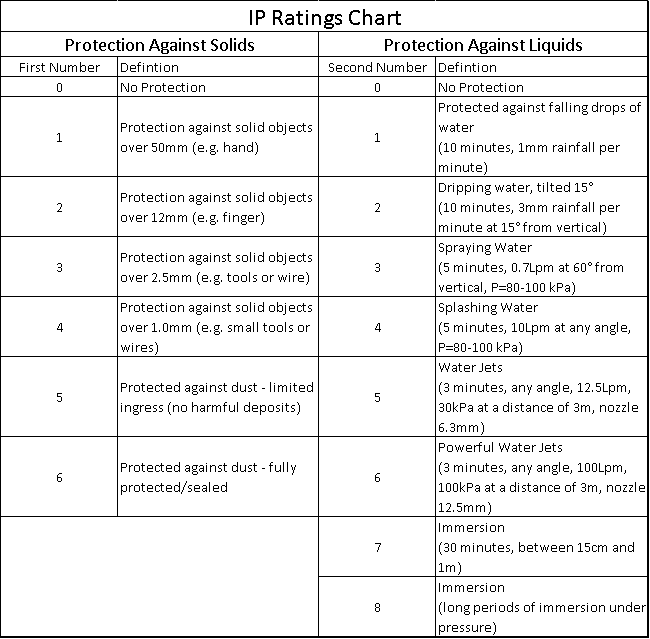

First, a little background on IP ratings. IP ratings consist of two numbers: the first, from 0 to 6, deals with the degree of particulate ingress, the second, from 0 to 8, deals with liquid ingress. Both start at a rating of 0, which is unprotected, and go up from there. The IP Ratings are explained in the table below.

In terms of particulate ingress, 1 to 2 are fingers or larger, 5 is dust protected (non-hazardous), and a rating of 6 is dust-tight.

Water similarly scales through dripping water and rain (1 to 3), splashes or jets in any direction (4 to 6), and immersion (7 and 8). The tests are specific in terms of the number of nozzles, and IEC 60529 should be consulted when setting up any tests.

Cleanability

When it comes to IP ratings, more isn’t necessarily better. Part of the Risk Assessment of the device involves cleaning of the device for repeated use. Cleaning protocols are required to be tested with no unacceptable risks (including any sterilization that is required), and that substances used in cleaning must be compatible with the device (Clause 11.6 in IEC 60601).

If the device needs to be cleaned, having a completely sealed device may not be required. In fact, sealing may actually cause cleaning failures. Sealing the device to IP68 may create small crevices where seals are located which could allow bioburden to build up to unacceptable levels. Sealing through ultrasonic welding or adhesives will require significant validation (both in terms of cleaning, as well as the manufacturing process itself) and add cost to the device which may not be required.

What is the normal orientation?

If your device is pole mounted, or has its own cart, then the normal orientation of the device would be always considered vertical, and a rating of IP x2 is likely sufficient. IP22 or 32 may be all that’s required (there are a number of IEC 60601 clauses which deal with accessible parts such as 8.4.2 – the test finger would pass through IP2x but not IP3x holes).

The clauses in 60601 discuss some hazardous situations, and give examples such as wetted uninsulated electrical components, or liquid bridging electrical insulation, but the hazardous situation could be any risk affected. Leakage current or dielectric tests are often required after ingress testing. The following list summarizes the requirements:

- Reservoirs need to be able to be filled to 115% capacity without wetting any means of protection

- Transportable equipment need to be able to be tilted to 15° without creating a hazardous situation (after being filled to 115%)

- Liquids poured on to the top of the equipment shall not create a hazardous situation (the type, volume, and duration of fluids to be determined through the risk management process)

However, hand held or body-worn devices may require a significantly higher rating as the normal operating conditions of the device may be any orientation during cleaning.

Join over 6000 medical device professionals who receive our engineering, regulatory and commercialization insights and tips every month.

Heat dissipation

If the device generates a large amount of heat, it may be impossible to meet IP 68 if air circulation is required for cooling. Device maximum surface contact temperatures need to be kept below 43°C, and that could be a significant design challenge in a sealed device. The design of the device will have to incorporate any heat dissipation strategies that meet the IP requirements of the device, and that is better done early in the design cycle of the device.

Consider IP ratings early in the design process and choose the right rating to reduce the cost of your device. Not only that, but choosing the right rating may reduce the amount of validation required, allow serviceability, and improve how your device is received in the marketplace.

Final Thoughts

As mentioned at the beginning of this blog, medical device enclosures need to be classified according to their requirements per IEC 60529, or IP rating (ingress protection rating). Pay particular attention to Cleanability, Orientation, and Heat Dissipation when addressing water ingress and use the tips and information provided above to help you successfully address water ingress in your medical device. See my colleague’s blog on ingress for home healthcare medical devices for additional information on the subject.

Medical Device Drop Test and Push Test are part of IEC 60601-1 and common in medical device product design & development projects. Check out our blog describing two of the most common mechanical tests that medical device designers may want to perform in-house before sending a device for third party testing.

Dana Trousil is a StarFish Medical Mechanical Engineer Team Manager for Product Design and Development. He has successfully launched many products, with experience in a variety of processes, including NPI for medical devices.