Working with StarFish Overview

Overcoming MedTech Development Challenges

Shaping the Future of MedTech in a Shifting Landscape

As healthcare systems face unsustainable costs and an increasing prevalence of chronic health conditions, the demand for value-based MedTech innovation has never been greater.

The industry is shifting toward solutions that improve patient outcomes while simultaneously reducing costs for healthcare providers. Additionally, a growing trend toward decentralized care is bringing diagnostics, therapy, and drug delivery closer to the patient. This shift prioritizes the development of products designed for both healthcare professionals and home users, with a focus on user-friendly interfaces and direct-to-consumer therapeutic solutions.

At StarFish Medical, we help companies navigate this evolving landscape by turning visionary ideas into commercially successful products. With 25+ years of experience and a track record of success across 1,000+ programs, we combine deep technical expertise, regulatory foresight, and user-centered design to create MedTech solutions that make a meaningful impact. Whether you’re an entrepreneurial startup building from the ground up or a global enterprise seeking to drive innovation within an established framework, we tailor our approach to fit your needs.

Why Partner with StarFish?

At StarFish, we drive value-based innovation using emerging technologies to tackle today’s biggest challenges. Our passion lies in solving complex technical problems, ensuring that products are not only functional but also commercially viable, scalable, and intuitive for users.

Our team is skilled at uncovering the root causes of challenges, ensuring fully informed and effective product development. Wherever possible, we help create new intellectual property (IP) for our clients, building equity and long-term company value.

We work with emerging startups to support the realization of their visionary products and assist established enterprises by providing lean innovation, flexibility, and problem-solving expertise within structured corporate environments.

Let’s Build the Future of MedTech Together

First Principles Design: Solving the Right Problems First

At StarFish, we take a First Principles Design approach, asking fundamental questions to break down complex problems into their core truths. Rather than applying pre-existing solutions, we seek to understand what constraints truly exist, what is possible, and how to build from the inside out. This approach allows us to push the boundaries of what’s possible while maintaining a clear path to commercialization.

- We look deeper to uncover the fundamental truths behind a challenge

- We solve the right problems, ensuring innovations address real needs

- We get the fundamentals right, building robust, scalable solutions from the ground up

Regulatory Considerations Without Compromising Innovation

While regulatory compliance is always a key factor, we believe it should enable—not stifle—innovation. Our team ensures that regulatory strategies support, rather than constrain, the development of breakthrough medical devices. By integrating regulatory considerations early, we help clients avoid costly setbacks while maintaining the flexibility needed for innovative problem-solving.

- Early-stage regulatory insights prevent roadblocks without limiting design possibilities

- Balanced approach between risk mitigation and creative technical problem-solving

- Proven success in achieving FDA, MDR, and IVDR approvals

Balancing Speed, Cost, and Innovation

In a competitive market, companies need to move quickly—but without sacrificing quality or burning through capital. Our milestone-driven approach keeps development on track while balancing cost, speed, and risk.

- Agile development methodologies accelerate time-to-market

- Investor-ready roadmaps align technical milestones with funding cycles

- Engineering expertise ensures robust, scalable solutions

From Prototype to Scalable Manufacturing

Transitioning from concept to production is where many MedTech products stall. We design for manufacturability (DFM) from day one, ensuring seamless scale-up to clinical trials and full production.

- In-house cleanroom manufacturing for clinical trial units

- Tech transfer expertise to contract manufacturing partners

- Supply chain and material sourcing strategies for production resilience

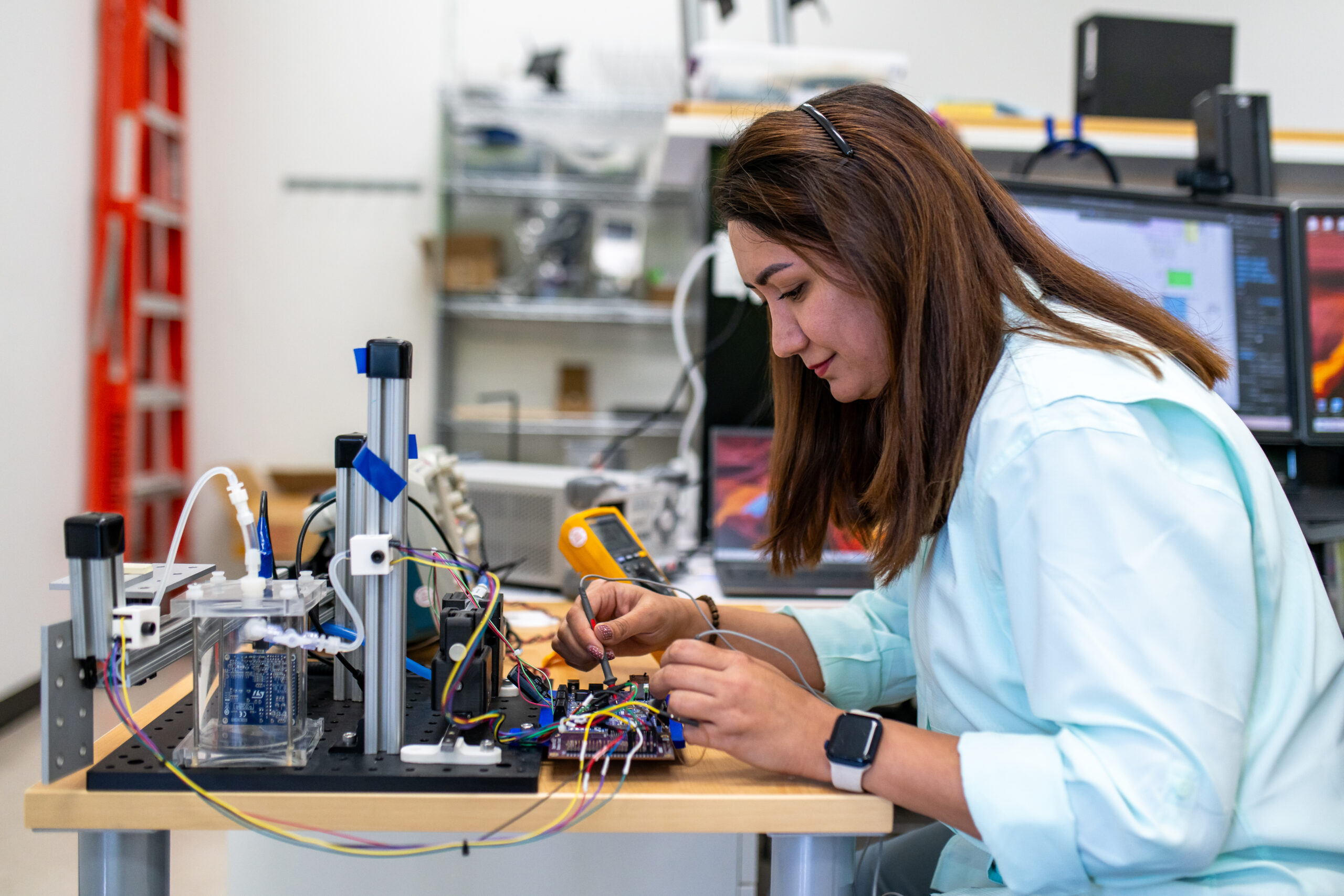

Science-Driven Engineering for Precision & Performance

Successful MedTech devices require scientific rigor and engineering precision. Our multidisciplinary team of physicists, biomedical engineers, and data scientists ensures that products deliver clinically accurate, repeatable results in real-world applications.

- Expertise in imaging, diagnostics, physiology, and therapeutic systems

- AI, ML, and data-driven device integration for next-gen MedTech solutions

- Technical depth ensures regulatory compliance and clinical reliability

User-Centered Design: Ensuring Real-World Usability & Adoption

Devices must be intuitive for both healthcare professionals and patients. Our human factors engineering approach optimizes industrial design and usability to drive adoption and improve patient outcomes.

- Ergonomic and intuitive industrial design for clinical and home use

- Iterative usability testing ensures seamless real-world adoption

- User experience research informs product development decisions

Ready to bring your vision to life?

Tailored Solutions for Startups & Entrepreneurs

We recognize that MedTech companies operate with different priorities, whether they are startups seeking cost-conscious, investor-aligned development or enterprises needing scalable innovation and regulatory expertise.

For Startups

- Lean development strategies to optimize resources

- Technical roadmaps designed to meet investor and regulatory milestones

- Support in bridging scientific discoveries to commercial success

For Enterprises

- Innovation-driven solutions that integrate seamlessly into established systems

- Scalable product development strategies aligned with corporate objectives

- Expertise in regulatory navigation, risk management, and compliance

Explore Our Services

Let’s Build the Future of MedTech Together

Whether you’re a startup bringing a new innovation to life or an enterprise navigating the next wave of MedTech disruption, StarFish Medical is your partner for success.

Let’s talk!

Contact us today to explore how we can bring your MedTech innovation to life.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.