Accommodative Intraocular Lens Technology Explained

In this episode of MedDevice by Design, Ariana and Mark explore how accommodative intraocular lens technology may one day restore natural vision for people who require cataract surgery or suffer from presbyopia. As Mark shares, traditional bifocals are not ideal, and new lens solutions may offer better outcomes.

What Is an Accommodative Intraocular Lens?

When cataract surgery is performed, the natural lens of the eye is typically replaced with a hard plastic lens. Unfortunately, this artificial lens lacks the ability to focus on both near and far objects. An accommodative intraocular lens seeks to solve this problem by mimicking the eye’s natural focusing ability. The lens responds to the eye’s ciliary muscles, allowing it to adjust its shape and focal distance, similar to a healthy, youthful eye.

The Challenge of Developing These Lenses

Currently, most accommodative lenses on the market fall short of fully restoring accommodation. Mark mentions products like Crystalens, which offer some adjustment but not enough for full reading and distance vision without glasses. For many patients, achieving about 1.5 diopters of accommodation is still a challenge. This technical hurdle makes developing a truly effective accommodative intraocular lens complex.

Market Demand and Development Pipeline

As discussed, the market for intraocular lens implants is large and well-established, creating a strong business case. Several companies are actively working on next-generation accommodative intraocular lenses. Mark mentions companies like LensGen, JellySea, Omniview, FluidVision, Synchrony, and TiaVision, all working through clinical studies. However, none have reached full FDA clearance yet.

Why This Lens Technology Matters

Accommodative intraocular lenses offer significant potential to improve quality of life for millions of patients who want to reduce or eliminate their dependence on glasses after cataract surgery. While regulatory pathways and technical feasibility remain hurdles, these emerging devices continue to generate strong interest across the ophthalmology community.

Enjoying MedDevice by Design? Sign up to get new episodes sent to your inbox.

Related Resources

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.

For manufacturers of novel devices that can make a significant impact to patient health, the goal of the program is to offer a path to streamlined and potentially faster market entry without sacrificing the rigour around ensuring safety and performance.

When I was starting out in medical devices, the discussion focused on the possibility of an internet of things and the promise of “big data” about everything.

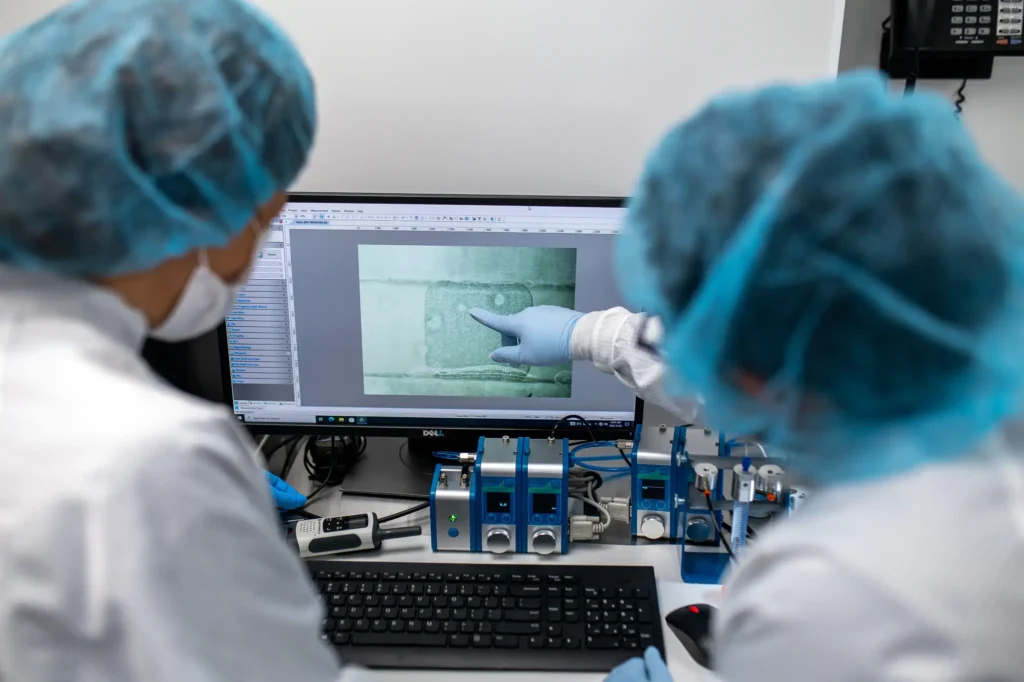

With the release of ISO 14644-5:2025, Cleanrooms and associated controlled environments, Part 5: Operations, the standard places increased emphasis on operational discipline, human factors, and contamination control behaviour.