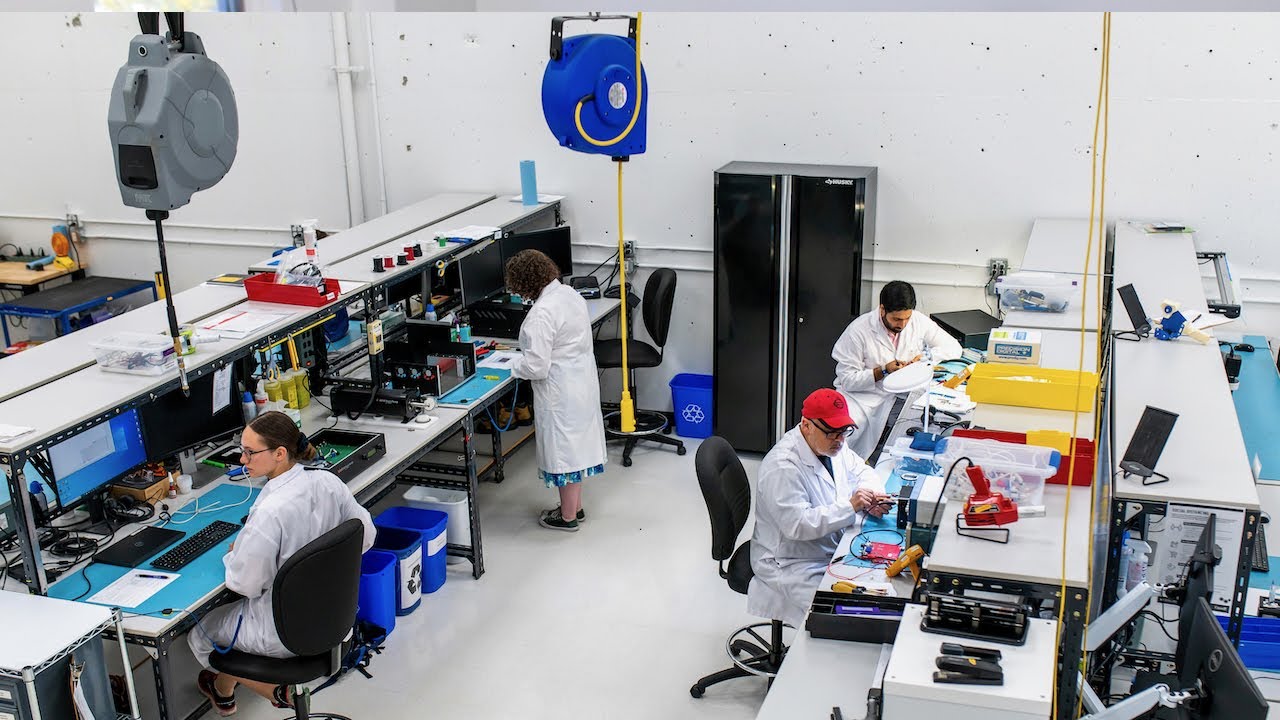

Supply chains make or break margins in low volume medtech manufacturing

There are many hurdles when trying to get to market with small volumes. With careful planning and smart strategic decisions you can create an environment that enables controlled growth and provides targeted cost of goods solutions.

In the design phases of a medical device, Bill of Materials (BOM) cost is an important element in product acceptance. It is defined and reviewed at all development gates. The decisions you make in the development cycle will define your cost of goods or the BOM you hand over to your medical device manufacturer.

Here are 3 areas of trade-offs to consider when launching your first builds of low volume medical devices:

Your first units will cost you more

First devices cost more, so do not expect to meet final BOM cost targets right out of the gate. Here are the reasons why:

- Your manufacturer (even if in-house) needs time to familiarize themselves with your device. They will not be as familiar with the first device manufactured as they will be on number 100.

- Initial volumes will probably be low and ordering sporadic. This does not help smooth or optimize the supply chain. Predictable, high volume reduces costs.

- Design for Manufacturing (DFM) inputs from your contract manufacturer may trigger BOM modifications. The initial DFM input is generally collected during the first runs in manufacturing. They refine the inputs from your alpha and beta builds for manufacturing optimization. This sets the stage for higher volumes and lower manufacturing costs per unit.

Lot Size vs Inventory value

- If initial volumes are low, it may not make sense to buy 1000’s of a particular part when you only need a few. Consider taking a slightly elevated BOM cost at the start of your launch until your sales have smoothed and a solid demand profile emerges. A rule of thumb I have always used is to order only what you can consume in 90 days or less. Of course there are exceptions, but for the most part this holds true.

- Low value items are good candidates for high Minimum Order Quantity – these have the lowest risk.

- High Value items are best suited to be purchased on demand with minimum safety stock on hand. Overall lead time for the finished device are generally highly dependent on the procurement lead time for these components.

- DFM inputs from your manufacturer (in-house or contract) may trigger BOM modifications. You will need to balance between risking potential obsolete inventory or lowering costs for higher component order quantities.

Tooling Costs- low volume medical devices tooling charges can add up fast!!

- Tooling charges for custom plastic housing can run anywhere from $2000-$35000. It may be worth considering machining your first housings instead of tooling up immediately. The benefit is you can defer the tooling costs until your design is more mature and your sales volume increases. The flip side is your per unit BOM cost may increase slightly. It is a trade-off that is worthy of some careful consideration.

- Work with your manufacturing team to understand the unique risks and opportunities for producing your device. Your first runs may still be more expensive than those later on, but the difference will be significantly less—and your supply chain will make better-informed decisions along the way.

Laura Meyer is a former Supply Chain manager at StarFish Medical. A Lean facilitator, Laura helps optimize supply chains for client prototypes and manufacturing. She happily shares her expertise with colleagues and clients.

Images: StarFish Medical

Learn more: Calculating Medical Device manufacturing costs.