Lessons from Real-World Device Testing

In this episode of Before the Build, Eric Olson and Paul Charlebois explore the unpredictable nature of real-world device testing. Even the best-designed devices, prepared with careful simulations and usability studies, can behave very differently when used in actual clinical or emergency situations.

Eric opens by reflecting on the limits of design planning. Teams work hard to understand workflows, but sometimes no amount of mockups or lab testing can replicate the stress, urgency, or unpredictability of real life. Paul recalls a neurosurgery case where a circulating nurse struggled with a specialized cutting device. In the dark, under pressure from the surgical team, she had to fumble with instructions while the surgeon demanded immediate action. The moment highlighted how hard it is to simulate stress during usability studies and raised important questions about testing devices under realistic conditions.

When Training Meets Reality

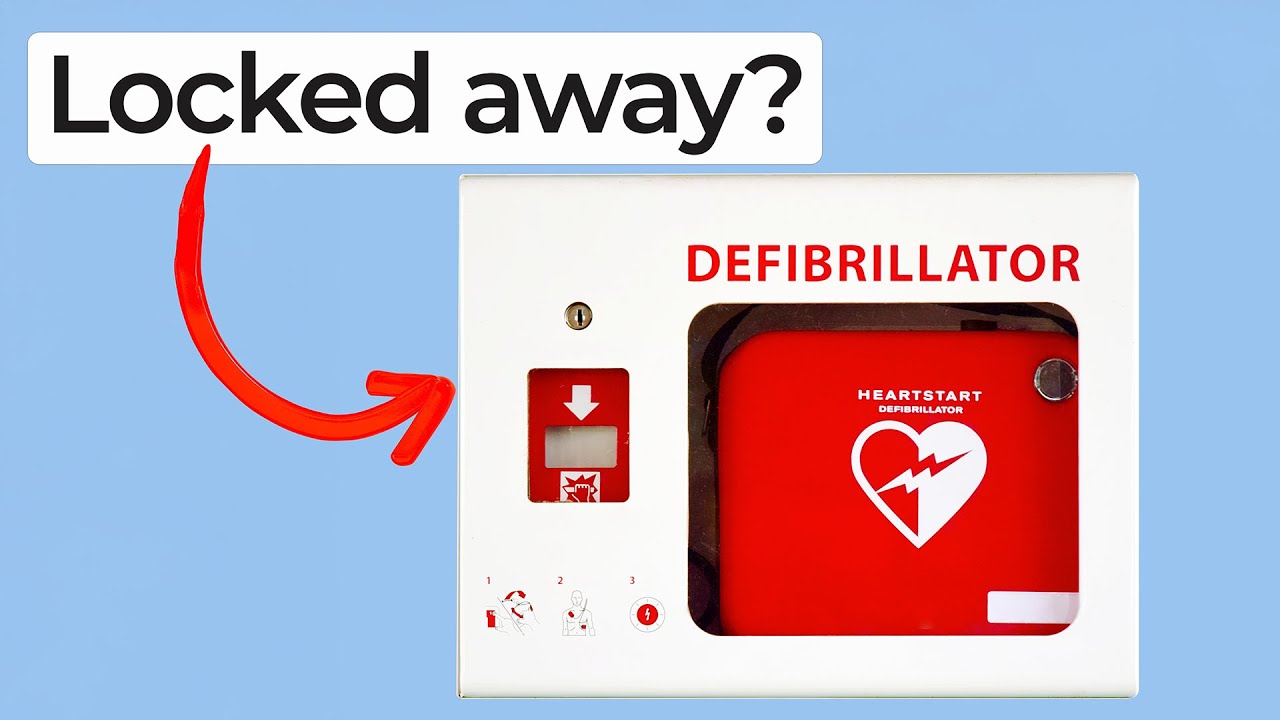

Eric and Paul share additional examples, such as automatic external defibrillators (AEDs). These life-saving devices are designed for simple bystander use with clear prompts and automation. Yet in practice, many AEDs end up locked in cabinets, hidden from view, or only known to a few trained employees. The gap between intended usability and real-world access shows the importance of considering full context during real-world device testing.

Another observation came from an epidural case. The anesthesiologist expected a straightforward procedure with a cooperative nurse as the patient. Instead, the situation turned chaotic when emotions ran high, leaving the researchers to realize how quickly assumptions can collapse. These moments, while unplanned, create some of the most valuable insights for improving device design.

Why Unpredictability Improves Design

As Paul notes, what feels like an “edge case” may actually reveal critical lessons. Unexpected reactions and stressful environments expose hidden design flaws and usability challenges. Ultimately, testing devices in real-world conditions helps teams create safer, more effective solutions that perform in both calm and chaotic situations.

Watch now to hear Eric and Paul discuss the stories that shaped their understanding of how unpredictable use can drive better MedTech design.

Enjoying Before the Build? Sign up to get new episodes sent to your inbox.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.