Bio Break: Addressing Shear in Drug Delivery Device Design

In this episode of Bio Break, Joris van der Heijden and Nick Allan explore one of the most critical challenges in drug delivery device design: shear stress. When designing systems for biologics and gene therapies, avoiding shear stress is essential to ensure the viability and activity of biomolecules like proteins, antibodies, and viruses.

Joris provides a comprehensive explanation of shear, defining it as the pressure and force that can disrupt or inactivate sensitive biomolecules during fluid transport. Whether caused by abrupt fluid path changes, bubbles, or high-friction pumps, shear poses a significant risk to the efficacy of advanced therapies.

Key Takeaways from the Episode

- Understanding Shear Stress: Shear occurs when fluid is forced through abrupt changes in its path or exposed to uncontrolled movement. For biologics, shear can lead to molecule clustering or inactivation, rendering treatments ineffective.

- Design Solutions to Reduce Shear:

- Optimize Fluid Pathways: Use simulation tools like computational fluid dynamics (CFD) to identify and eliminate areas with abrupt fluid movement. Rounded pathways and smoother transitions help minimize turbulence and pressure.

- Low-Shear Pumps: Select pumps specifically designed to handle biomolecules gently, preserving their activity and integrity.

- Testing for Success: After designing a low-shear system, functional testing is critical. For example:

- Measure the viability of cells after passing through the device.

- Verify that antibodies, viruses, or other biomolecules remain active and effective post-delivery.

By addressing shear stress during the design phase, drug delivery devices can ensure biologics reach their target intact and active, maximizing therapeutic impact. For developers working with advanced therapies like gene therapy products, these design principles are essential to delivering cutting-edge care to patients.

This episode is a must-watch for engineers, product designers, and healthcare innovators seeking to tackle the complexities of drug delivery systems. Learn actionable strategies to refine your designs and improve the outcomes of sensitive therapeutics.

Addressing Shear in Drug Delivery Device Design

Related Resources

What does empathetic medical design really look like in practice? Eric and Paul discuss how emotional insight from field research can profoundly impact the design of medical devices

Despite costing just pennies, syringes pack an extraordinary amount of design and manufacturing complexity. From precision-molded barrels to breathably sealed packaging, these tools are more than meets the eye.

Ariana and Mark examine the complexities of endoscope reprocessing, one of the most difficult tasks in medical device hygiene.

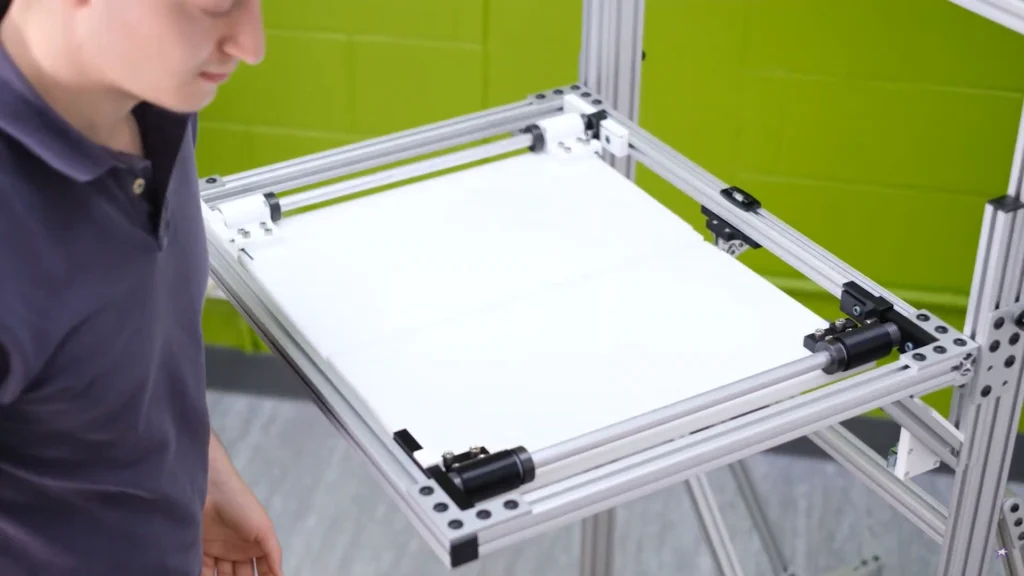

Medical device drop testing helps ensure that products and packaging survive real-world handling. We demonstrate in-house drop testing on an actual device and its packaging using a custom-built drop tester.