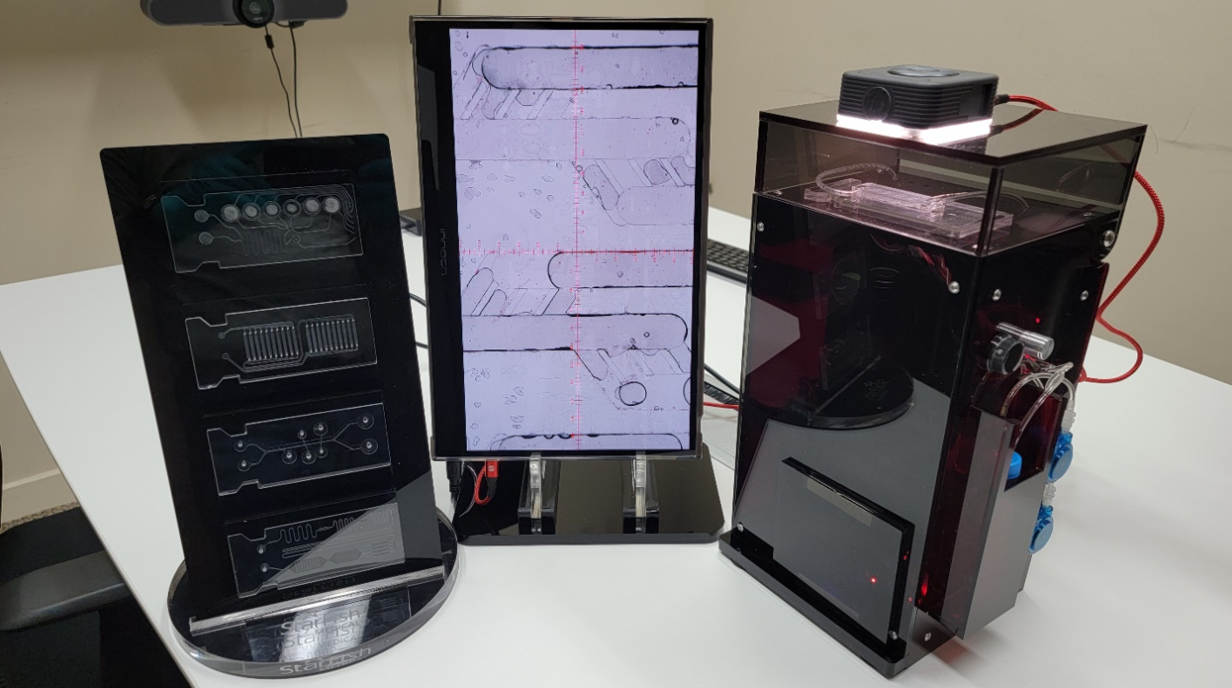

Building a Customized Microscope for a Microfluidics Application

Several companies offer microscopes specifically designed for microfluidic applications and cell imaging, but a limited budget requires building a customized microfluidics microscope that is affordable.

In addition to being price prohibitive, in most cases, the microscopes do not readily fit the specific requirements for a particular microfluidic application.

If a commercially available microscope meets all the requirements of the application, it is often advisable to use such a microscope.

However, for applications that require specific tweaks and customization, this blog outlines ideas for building an affordable customized microscope for monitoring droplet generation in a microfluidic format.

A standard microscope is not ideal or appropriate due to the space required to position the microfluidic device along with all its required interfaces and connectors. There are application-specific microscopes available commercially, however, adapting them to microfluidic purposes may require customization and additional fixtures.

Such microscope may require a different light source or fluidic fixtures, and the lenses may need to be replaced with large working distance objective lens to provide space for the microfluidic device and its accessories on top of, or under the lens.

Listing the requirements

As the first step in the design process, it is important to identify your requirements. These will serve as a guide to designing and building a microscope that will be appropriate for your application.

Our goal for this blog is to design and build a microscope to monitor droplet generation. Monitoring the droplets as they flow through the microfluidic channels is important for quality control purposes. Viewing the droplets will enable the operator to adjust parameters such as the flow rate, throughput, and size of the droplets.

The microfluidic cartridge requires a channel depth of 50 um and width of 100 um and requires 20 um orifices. The viewing area must be approximately 1 cm x 1.5 cm with a working distance from the lens to the cartridge of at least 50 mm. A bright field lighting using an LED is a good solution.

The system must have an easy-focusing feature and the ability to digitally zoom “in” and “out”. There must be a monitor that can be attached to the camera via HDMI. The microscope must incorporate an actuation system for fluidic flow and must be portable for desktop use.

Lastly, the overall cost must be less than US $2500 including the enclosure and optical sub-system.

Identifying critical components

A sketch of system architecture includes the following:

(1) an enclosure with a top cover to protect the cartridge from contamination and to mount the light to illuminate the cartridge from the top, and a bottom enclosure to house the other major components,

(2) a camera that is able to capture and save high-resolution images and video that can be displayed on the monitor,

(3) an optical sub-system that includes an objective lens, filter, and a vertical translation stage for focusing the cartridge channel,

(4) peristaltic pumps with a controller to flow the fluids from an external reservoir to the channel,

(5) a light source for illuminating the droplets inside the channel as they are being generated,

(6) an HDMI or USB connector for image display,

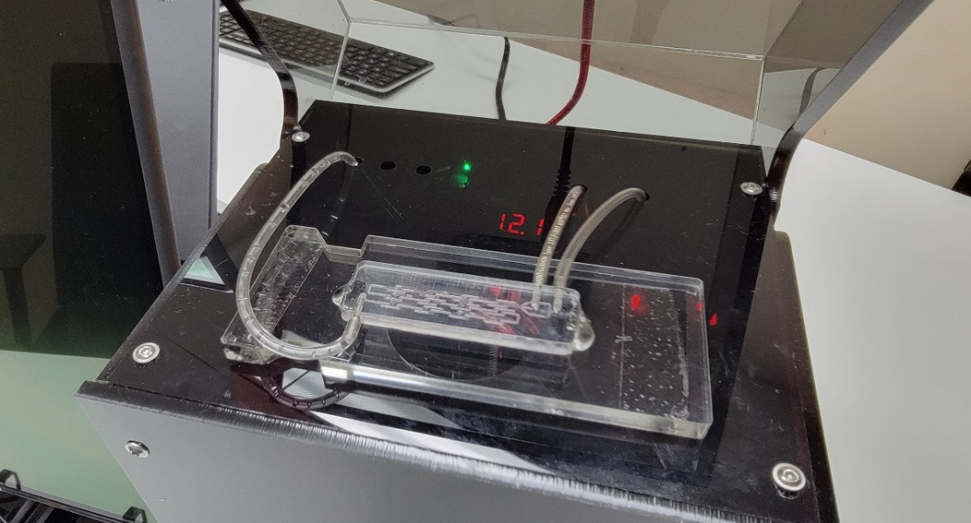

(7) a clamping device to position and align the cartridge to the viewing area, and lastly,

(8) a 12 V DC source to power the entire system.

The critical components for this build are (a) the camera and optical paths, (b) fluidic actuation, and (c) the enclosure to house the components with a user interface.

(a) Camera and optical path. Selecting an appropriate camera and optical components is tricky considering the identified requirements. On the technical side, there are several considerations to think about such as sensor size, type, pixel size, frame rate, resolution, optical performance for the intended use, and cost.

For this build, the cost is the primary driver, and hence, a matrix of potential cameras that fit the budget and performance was created. Most cameras commonly used for microscopes meet these requirements and include software for image viewing, capture, and analysis.

A camera with autofocus is desirable, but such cameras tend to be expensive. Instead, manual focus using a Z- translation stage will work as an alternative. The optical components were selected based on vendor’s specification and provide a working distance of 50-80 mm with a depth of field of 0.018-6.24 mm.

An optional 2x lens attachment was added to increase magnification.

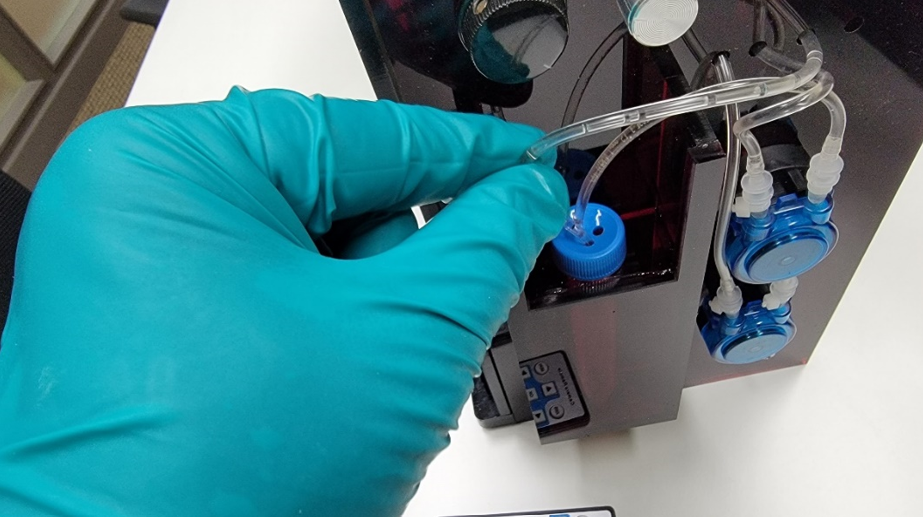

(b) Fluidic actuation. The top cartridge loading option is more practical and easier to use. The operator can visually position the microfluidic cartridge and align it with the lens and camera.

Flowing fluids to the cartridge requires two peristaltic pumps installed on the side of the enclosure to avoid fluids dripping inside the microscope if there are leaks. The actuation timing and flow rates are controlled by the peristaltic pumps, which are connected to external reservoirs.

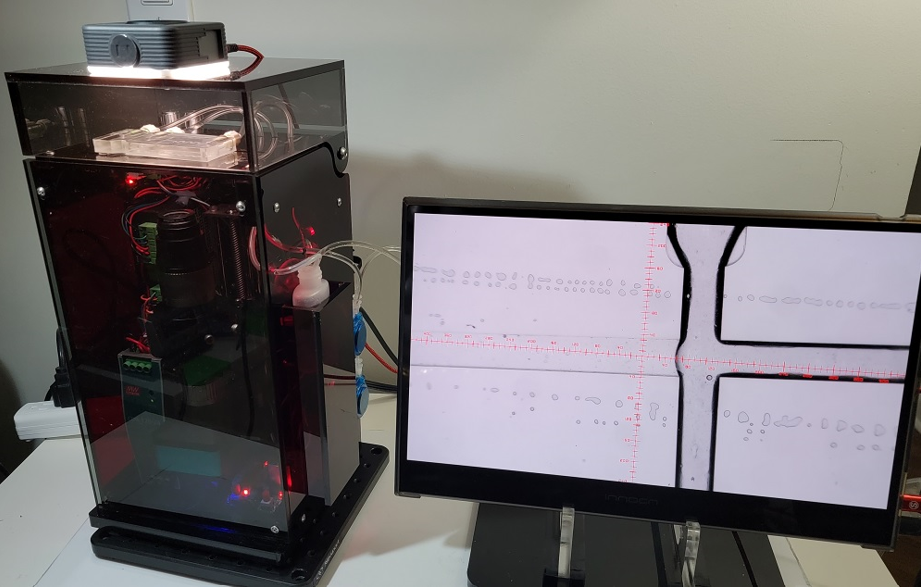

(c) Enclosure and user interface. The enclosure was designed based on the footprint of the camera, the optical path components, the working distance, and the dimensions of the cartridges and their accessories. The microfluidic droplet generator cartridge is positioned on top of the enclosure while the camera and optical system are inside the bottom enclosure.

The material used for the enclosure is acrylic, which can be easily cut into appropriate panels using a laser cutter. The acrylic panels are screwed together to form the enclosure, which enables easy repair and maintenance.

A minimal user interface was employed which includes power switches and knobs for fluid actuation.

Maintaining the build cost to target

The goal is to make the cost as low as possible while attaining the maximum functionality for our intended use.

Overall cost is the limiting factor. For the build, only parts necessary to run the functions of the microscope were used. Another important consideration was availability of the selected parts in terms of lead time, as well as shipping, duties, and taxes, which could significantly increase the cost.

Below is a list of the parts and components, their specifications, and their costs.

Parts | Specifications | Cost (USD) |

| 1. Enclosure | Acrylic ½ Inch and 6mm thick Laser cut per CAD design | 155 |

| 2. Camera | 4K camera @60fps, 12MP 1” Sony CMOS IMX sensor, Pixel size: 1.55 x 1.55um | 900 |

| 3. Optical path and lenses | A compact lens, 145 mm with an objective lens Attachment, manual focus WD=86mm | 650 |

| 4. Fluid pumps | 0-50 mL/min Low flow peristaltic pump, 12 Vdc Low noise: 55 dB | 105 |

| 5. Light source | RGB LED multicolored 2500-9000K dimmable with diffuser | 30 |

| 6. Vertical stage | Small X translation stage for focusing | 220 |

| 7. HDMI or USB connectors | Connector for monitor and LED lights. | 25 |

| 8. Clamping device | Screw clamp for microfluidic cartridge | 10 |

| 9. Power supply | 12 Vdc 3A, 90-240 Vac | 70 |

| 10. Monitor | 15.6-inch LCD IPS monitor High Resolution1080p FHD | 160 |

| 11. Other parts | PWM controller, plugs, outlets and tubing | 110 |

| Total Cost | US $2,435 |

Evaluating image quality

The completed microscope was evaluated based on output image quality and performance. The first test conducted was to evaluate the optical system’s ability to focus on the cartridge channel and produce an acceptable image of the droplets as they are being generated. Light settings were adjusted to optimize the image quality.

The second test is the integration of a fluidic flow to the channel to generate droplets. Using different flow rates, the captured video of the droplets flowing inside the channel were of good quality.

Lastly, a simple test for reliability was done. The custom-built microfluidic microscope was allowed to run for 48 hours continuously while regularly checking the image quality over time. There are some imperfections and limitations on the output quality, but as per the intended application and budget, the build worked perfectly!

Takeaways

A microscope to capture images or video is crucial in understanding the processes and control parameters in many microfluidic applications. Our customized microscope set-up provides an appropriate solution to view droplets as they are being generated.

The quality of the camera (sensor size, pixel size, etc.) and choice of lenses with respect to the working distance are crucial aspects in producing sufficient image quality. Manual image focusing is difficult and therefore, an auto-focusing camera (if available) or a focusing stage is highly recommended.

Overall, we are satisfied with the build, and will use it as a benchtop tool for microfluidic research and product development work.

If you are interested in receiving the step-by-step procedure to build our customized microscope, parts specifications, the design, and/or suppliers, please connect with us.

Images: StarFish Medical

Lorenzo Gutierrez is the StarFish Medical Microfluidics Manager. Lorenzo has extensive experience translating point of care assays to microfluidic cartridges. His microfluidics portfolio includes developing a polyvalence instrument for early infant diagnostics at Chipcare.