Five Critical Considerations in Designing Microfluidic Cartridges

Developing microfluidic devices can be a daunting task not unlike the development of other medical or in-vitro diagnostic devices. Development typically arises from the need to miniaturize and automate existing assays for microbiological applications such as ELISA, PCR, flow cytometry, etc. This blog covers key considerations which we have found increase the chances of success during the early phases of microfluidic cartridge development.

These considerations lay the groundwork for thinking like a microfluidic cartridge developer. They include design requirements, concept development, assembly process, detailed design and quality testing of microfluidic cartridges.

Below are five critical considerations in designing and building microfluidic cartridges.

1. Design Requirements

A review of the assay is crucial to the success of cartridge design and implementation.

Assay development requires a good understanding of the reagents used and their properties, such as: viscosity, chemical compatibility, and required volume. It is also important to know how the reagents are introduced in the cartridge. For example, are they preloaded into the cartridge or will a blister package be used instead? The type of packaging will affect the storability of the reagent, its effectiveness and interactions with other reagents. In some microfluidic devices, freeze dried reagents are preferred in order to avoid liquid handling which tends to complicate the design.

The fluidic properties of the reagent can determine how the fluid is moved in the reservoir and channels. It is recommended to create a detailed list of features and processes involved in the assay protocol, for example: the number of reagents in the protocol, volumes, fluidic properties, volatility, material compatibility, biocompatibility and composition (i.e., beads, cells).

Actuation methods must also be identified from the requirements. These can include positive pressure, vacuum, electrostatic, ultrasonic, capillary action or fluidic pumps such as diaphragm, piston, film or even peristaltic pumps.

Actuation timing and flowrates are another important set of requirements. Considering that the microfluidic process is the miniaturized version of the laboratory workflow, proper timing of each process at a predetermined volume is crucial. Some assays include a target assay protocol timing per unit operation such as: introduction of the sample, mixing, metering, incubation, pre-filtering, separation, sorting, binding and washing steps. We recommended to list all the unit operations with corresponding reagents, volumes, processes, timing, flowrates and other protocol specific parameters.

Including these considerations in design requirements will guide the engineers in developing a cartridge concept that implements the assay protocol efficiently with manufacturability and cost in mind.

2. Conceptualization

With clear requirements, an initial design concept can be drafted. If the design requires off-the-shelf (OTS) components, specifications of such OTS parts must be reviewed, taking into account their compatibility with cartridge materials and feasibility of integration into the cartridge. OTS components include pumps, valves, filters, tubes, ports, interfaces and the like. Take several OTS options and review advantages and disadvantages including whether to use OTS or build the component as part of the cartridge. In most cases, OTS components drive the overall dimensions and performance of the cartridge. Be very careful with this integration.

Other key elements of initial cartridge design are the unit operations to be done inside the cartridge. These include sample ingress and egress, reagent storage, mixing, metering, material filtration, analyte detection and more. Sample ingress and egress are very important to the user interface design. The introduction and collection of the sample dictate the “usability and human factor” aspect in handling the cartridge. Medical practitioners will find poorly designed cartridges difficult to use, or, in some cases, even pose a hazard.

Four elements are challenging in the cartridge design.

- Reagent mixing in a microfluidic cartridge is a standard unit operation. This includes mixing biological samples with other reagents (i.e., lysing, tagging, reconstituting, diluting and incorporating). Mixing inside the cartridge can be done in a number of ways: by shaking, magnetic mixing, use of vortex, application of acoustic pressure, material transfer or other mixing techniques implemented in the cartridge itself.

- Sample metering. This is one of the most difficult features to implement in the cartridge. Because microfluidic channels handle fluid at sub-microliter volumes, accuracy in metering fluids is of utmost importance. In assays that require precise measurement, metering is a huge challenge. Metering is typically classified as passive or active. Passive metering uses predetermined channel and reservoir volumes to dispense desired quantities of reagents. Active metering uses sensors to actively monitor the volumes dispensed.

- Material selection. A number of candidate cartridge polymers have been tested in terms of machinability, biocompatibility, manufacturability and cost. Polymer properties, such as temperature performance, bonding, stability and optical characteristics, must also be considered. The choice depends primarily on assay chemistry biocompatibility. Manufacturability will also drive the ability of the yield and overall cost of the end product. Learn about traditional testing to verify polymeric environmental stress cracking (ESC) that doesn’t require any specialized or expensive equipment in this StarFish Medical blog.

- Analyte detection. This is particularly necessary for point-of-care devices and in benchtop equipment. In some designs, optical lenses can be integrated into the cartridge to facilitate imaging or electrical data collections.

3. Assembly Process

There are four elements in designing and determining the assembly process.

Assembly workflow. During and after conceptualization of the cartridge design, it is important to consider how the cartridge will be assembled. At low volume production, this may include methods such as laser cutting, embossing and micro milling of layers that can be assembled with adhesives or other bonding techniques. It is critical to understand the limitations of the assembly early in order to streamline the assembly process. Some steps in the cartridge assembly are: manufacturing of parts, cleaning, and integration of OTS components, stacking and quality control testing.

Assembly jigs and fixtures. Assembly jigs and fixtures are critical considerations during conceptualization and detailed design of the cartridge. They are dependent on dimensional tolerances of the individual layers and directly affect the tolerance stack-up of multilayer cartridge configurations. Considering these limitations early on provides an opportunity to do some crude and rudimentary “Process Failure Mode and Effect Analysis (PFMEAn the manufacture of the cartridge and helps avoid assembly issue pitfalls in early prototypes. Typically, this means simplifying the cartridge design and using larger channels where possible. This requires a good understanding of the design requirements and objectives of the prototype.

Quality control testing. Quality control checks should always be implemented on the design of the cartridge in order to ensure reliability and repeatability of performance. This includes things like inspecting dimensions within defined tolerances, as well as pressure decay tests and fluidic tests to check the functionality of the cartridge.

Assembly trial run. A pilot run of the assembly workflow provides an opportunity to debug and troubleshoot potential pitfalls in the assembly process ahead of production of units. It also provides a chance to make changes that increase assembly efficiency.

4. Detailed Design

During detailed design of the cartridge, the designer has to be very aware of the fabrication process to be used, experiment and iterate on the process in order to establish a set of rules that can ensure quality of the manufacturing process.

Iterations on cartridge design can be prototyped more rapidly in a streamlined process. Benchtop fluidic tests can be used to evaluate performance of different design aspects. Initial exploratory testing can then feedback to optimize the cartridge design. This approach uses a “fail fast” strategy to generate detailed design parameters based on empirical test data.

5. Quality Inspection and Testing

Microfluidic cartridges are typically single-use. Setting good quality control targets early in the prototyping phase helps ensure reliability and repeatability in prototype builds that increase yield in production. Five ways to monitor quality concerns associated with cartridge design are:

Fluid flow testing. To evaluate the performance of the cartridge, DI water or dyed dummy reagents are used during fluid flow testing. Using dyed water facilitates visual observations on the tested cartridge and is very effective in assessing the mechanical performance of the cartridge.

Detailed feature quality inspection. Detailed inspection of cartridge features such as size, surface finish, cleanliness and integration of OTS components. This initial inspection can be used to screen for critical features to be inspected in quality control checks during cartridge production.

Assembly and components potential failure mode. Address assembly failure mode analysis early in the cartridge prototyping phase to ensure success of cartridge assembly. Some challenges that are encountered during assembly include misalignment of parts, leakage issues due to bonding and improper integration of OTS components.

Critical parts ocular inspection and channel profile. From detailed inspection findings and design specifications, critical features should be determined and inspected as part of the quality control process. Channel profiles should also be inspected with a profilometer to ensure surface roughness and channel depth are within specification as they affect fluid flow parameters in the cartridge.

Pressure decay testing. Pressure decay testing can be used to set a benchmark for a successful seal of the microfluidic cartridge. This is done by pressurizing the cartridge at a pre-determined level and using the observed decay rate as an indicator of effective cartridge seal.

Conclusion

In summary, five critical considerations can serve as a guide for the successful design and prototyping of a microfluidics cartridge.

- Design requirements – A good understanding of the requirements and high-level objectives is absolutely critical

- Conceptualization – Requires a good understanding of the assay and workflow to be used

- Assembly process – Understanding the assembly process reduces cartridge failures

- Detailed Design – Careful detailing of design helps streamline the microfluidic cartridge build

- Quality Inspection – Increases repeatability and reliability of cartridge functionality early in the process

Microfluidic cartridge development can be a complex process. Prototype development must be carried out early in order to remove challenges that inevitably arise during production and testing. An iterative approach is essential; implementing a rapid prototyping process will help mitigate the risks associated with microfluidic cartridge development.

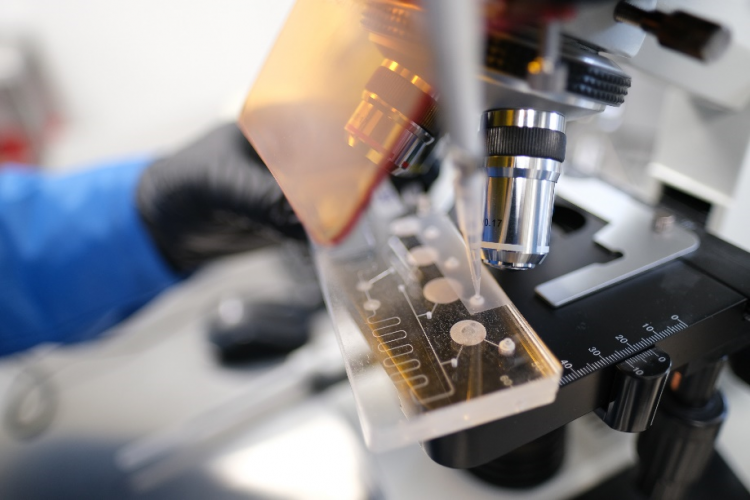

Image: StarFish Medical – Bioservices

Jurgen Frasheri is an Intermediate Mechanical Engineer at StarFish Medical. While a student at University of Toronto, Jurgen belonged to an engineering design club that develops autonomous underwater vehicles for international design competitions.

Discover eight methods and attributes of effective medical device design reviews that help produce a superior product.