Medical Device Design Transfer Process –

Tips and Common Pitfalls

Medical device design transfer is a critical phase in the development process, marking the transitory phase from the design and development stage to manufacturing. This phase ensures that the medical device continues to meet its safety, effectiveness, and regulatory compliance once production begins. It is the final phase in the development process and sometimes overlooks or underestimates the amount of time and effort required to ensure that final manufactured devices meet requirements.

Design History File and Design Transfer Readiness

User requirements, design specifications, test plans/protocols, and test reports ensure design outputs meet all design inputs. A gate readiness assessment matrix or checklist helps to check the design history file is complete. Manufacturing requirements are driven from these outputs so it’s very important that the specifications passed to manufacturing are well known and complete.

A technology readiness assessment can help to quantitatively assess the design maturity of various systems and subsystems in the device by ranking them with a readiness score. Low scores, for example, might carry risk of rework, or higher labour costs.

A manufacturing readiness assessment checks whether all manufacturing requirements are fulfilled and setup to manufacture the device. Requirements include supply chain, incoming inspection, inventory control, equipment/space, manufacturing staff, service and repairs, QA, shipping and receiving, etc.

Design Transfer Process

Per FDA 21CFR820.30h, “Each manufacturer shall establish and maintain procedures to ensure that the device design is correctly translated into production specifications.”

Per ISO 13485, “The organisation shall document procedures for transfer of design and development outputs to manufacturing. These procedures shall ensure that design and development outputs are verified as suitable for manufacturing before becoming final production specifications and that production capability can meet product requirements.”

A common pitfall in the medical device design transfer process is not having a well-defined design transfer procedure. Often, a lot of effort is put into the product development phase whereas the design transfer aspect gets neglected until the design transfer phase. Ideally if an existing design transfer procedure is not available or not well defined, it should be developed as early as possible concurrent to the development phase so when the product is ready for design transfer, the procedure is already in place.

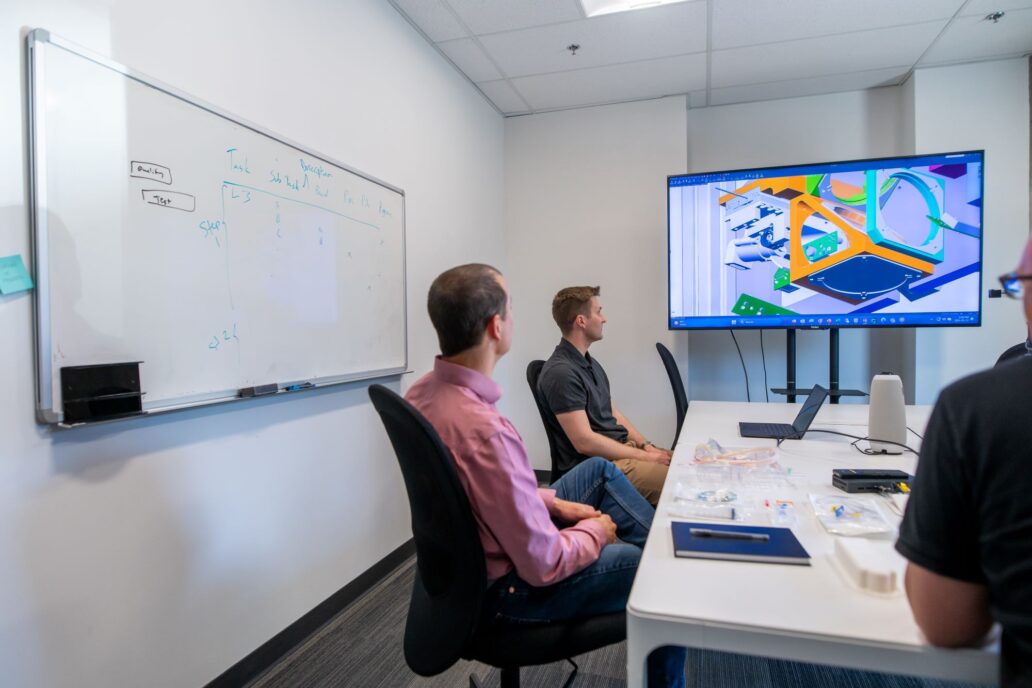

Team Collaboration/Communication

Effective communication between various teams including design, engineering, manufacturing, and quality assurance is vital. In particular, design for manufacturability and assembly should be factored into the design as early as possible. Manufacturing engineers should be included early in the development phase, rather than close to design transfer phase because design changes later in the process due to manufacturability issues may require reverification or design validation and cause significant delays to time to market.

Example:

A part that is prototyped using CNC machining may not have the proper geometry and optimization for injection molding post transfer and could result in undesirable molding defects requiring a part redesign.

PFMEA

Vigorous risk management in manufacturing (i.e. PFMEA) helps to anticipate potential challenges, hazards, and issues. Process and/or design changes can be implemented to mitigate potential risks.

A common pitfall is that the PFMEA is not done effectively to capture and mitigate all risks due to time and resource constraints, especially if the design and/or manufacturing process is complex. An ideal PFMEA requires a detailed breakdown of all steps with all associated risks, and it must be reviewed by the team to determine the RPN (Risk Priority Number), which can take a significant amount of time.

Another pitfall is that the PFMEA is done too late in the process, causing delays and reverification if design changes are required.

Process Validation

Processes where outputs can be 100% verified do not require process validation such as hi-pot/ground bond tests. Processes where outputs cannot be 100% verified would require process validation to ensure that the process is consistently within specs and control.

Process validation is required on processes that require destructive testing to verify, or where uncontrolled process inputs can lead to a change in process outputs resulting in failure, or where process inputs cannot be verified. Examples include adhesive application, sterilization, injection molding, and pouch sealing.

Installation qualification, operational qualification, and performance qualification should be performed to ensure that the output meets all defined requirements under all anticipated conditions of manufacturing. This allows the control limits to be established and determine whether they are within the spec limits.

Production supplier capabilities and new manufacturing methods should be assessed to ensure parts still meet design specifications consistently. For example, prototype parts are often sourced from prototype suppliers that use flexible manufacturing methods such as 3D printing; however, for manufacturing at scale, production suppliers are typically use different manufacturing methods that are more cost-effective at large scales (such as injection molding).

Product Reliability Testing

Though not a transfer activity per se, product reliability testing ensures the product is problem free for the design or expected life of the product. Sometimes, reliability testing may be cost, resource, and time prohibitive, and challenging to plan and execute. If reliability testing is not performed or performed diligently, there is a potential risk of field failures, which (depending on the severity and frequency of the failure) can have a significant impact on the manufacturer’s operations, finance, and reputation. This is a risk that requires careful consideration while balancing project timeline and cost vs potentially cost and logistics of product returns, recalls, or field servicing. It is highly recommended that reliability testing be performed before design transfer. Being proactive is a more cost-effective approach vs reacting when field failures occur.

Post Design Transfer Monitoring

A robust system should be established for monitoring the product post transfer such as a product return and change control process.

The product return process allows a manufacturer to monitor the number and frequency of field issues which may warrant a design change via a change control process. Process outputs results should be monitored and analyzed continuously to identify, troubleshoot, and resolve any anomalies within the process.

Conclusion

Medical device design transfer demands meticulous planning, collaboration across departments, and adherence to regulatory standards. Successfully navigating this critical phase allows the device to reach the market quickly as a safe, reliable, and effective medical solution.

Eddie Yeung, is a StarFish Medical Mechanical Engineer.

Images: StarFish Medical

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.

Learn how StarFish Medical led a consortium that created a Ventilator 2.0 therapy device in record time.