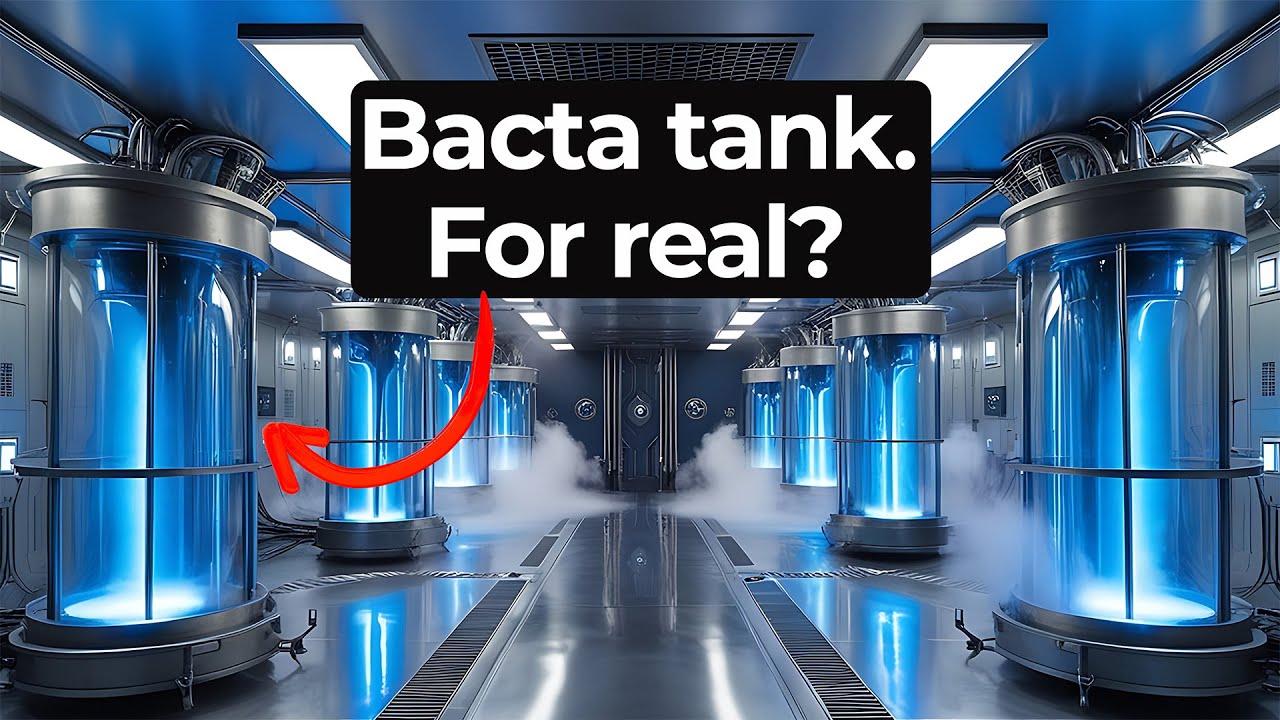

Star Wars Bacta Tank in Real Life

In this episode of MedDevice by Design, Ariana Wilson and Mark Drlik take inspiration from a scene in The Empire Strikes Back to talk about real-world parallels to the Star Wars bacta tank. Luke Skywalker’s full-body healing in this sci-fi medical chamber may be fictional, but several advanced wound care devices on the market today achieve similar results—on a smaller, more targeted scale.

The discussion starts with negative pressure wound therapy devices. These vacuum-assisted closures are often used for burns or trauma wounds, including those treated on the battlefield. By regulating pressure, they remove excess fluid, reduce swelling, and improve blood flow to help localized tissues heal faster.

From Bacta Tank to Hydrogel Dressings

Ariana and Mark also compare the bacta tank’s healing fluid to hydrogel-based wound dressings. These treatments regulate moisture, creating an optimal environment for healing. They can also be infused with antimicrobial agents to further support recovery. Hydrogel dressings are especially effective for burns and other injuries that require controlled moisture.

For more severe tissue loss, bioengineered skin substitutes provide another level of advanced care. These may include 3D printed matrices embedded with biological signals or living cells, which help promote skin regrowth over large wounds.

Why Full-Body Healing Tanks Stay in Sci-Fi

While Luke’s complete submersion in a bacta tank looks impressive on screen, Ariana and Mark explain why it would be impractical in real life. Different injuries heal at different rates, making localized treatments more effective. A broken bone, a burn, and a deep cut each require specific therapies tailored to the injury.

Watch now to discover how the galaxy’s most famous healing tank connects to real-life medtech innovation.

Enjoying MedDevice by Design? Sign up to get new episodes sent to your inbox.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.

For manufacturers of novel devices that can make a significant impact to patient health, the goal of the program is to offer a path to streamlined and potentially faster market entry without sacrificing the rigour around ensuring safety and performance.