The Forgotten Art of Tolerancing

Modern education seems to be leaving behind a crucial lesson: Tolerancing

After speaking recently with budding young engineering students, I was pleased to hear that many get consistent access to engineering technology in their high school and undergraduate programs. It’s fantastic that hands-on exposure to tools such as 3D printers are becoming more common. That is translating into the impressive quality of students we see apply every semester. However, despite all this hands-on experience, there is clearly one skill that these short-term design projects aren’t teaching: effective tolerancing.

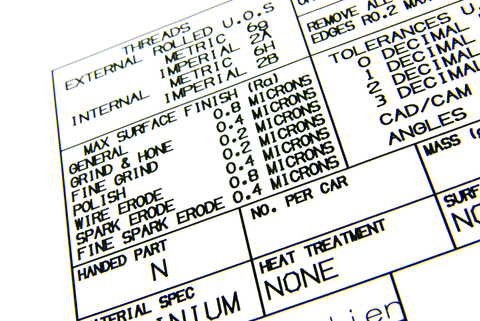

Tolerancing is not actually a technical term – I’m really referring to “an engineering tolerance”, or “a tolerance stack analysis”, but the colloquialism is certainly convenient. Tolerancing is the consideration of process accuracy (and, to some extent, precision) when designing a device or component. These are typically controlled in an engineering drawing, and need to be defined in such a way as to ensure the final product does what you want through its final form.

For example, a nominal design of a rotating system might include a 15.5mm diameter shaft in a 16mm diameter hole. However, in reality, a vendor might only be able to produce parts that are accurate to +/-0.5mm. Therefore, there’s a statistically weighted chance that the parts won’t fit (e.g., the shaft is 16mm and the hole is 15.5mm) or they won’t act like you want them to (e.g., a 15mm shaft wiggling around in a 16.5mm hole). The same is true for 3D printing, where the machine is only accurate to a certain amount, from a few microns to a few millimetres depending on the unit and its calibration (for more information see Nathan’s excellent blog on 3D printing here).

Why is this relevant to students (and professionals)? It’s simple: if a set of 3D printed parts doesn’t do what you want, you can usually just print them again overnight. However, because real-world, non-rapidly made parts typically take 2-8 weeks between the time you order them and the time they arrive, not thinking of tolerances can not only lose the cost of the part – which is often much higher than a 3D print – but also a lot of time.

Tolerancing is a vital skill to have as a design engineer on long term projects. Unfortunately, because it’s often irrelevant to students who often don’t pay for parts or their own time, it’s a skill learned on the job. I’d advocate that all engineering students (and, one day, curriculums) should make a concerted effort to consider tolerancing before having students create parts, even if the parts are easy to re-print. This will develop a mindset that leads into real life design practices, and may even save a bit of time right away.

I very much doubt that most real-world parts will be 3D printed any time in the next decade, so students from young to old will all need to learn about tolerancing sooner rather than later. That being said, the world is changing quickly; perhaps one day tolerancing for long lead-time parts will be, like, such a thing of the past, dude.

Nigel Syrotuck is a StarFish Medical Team Lead Mechanical Engineer and frequent guest blogger for medical device media including MD+DI, Medical Product Outsourcing, and Medtech Intelligence. He works on projects big and small and blogs on everything in-between. He apparently has no tolerance for no tolerancing.

Image credit: © Trombax | Dreamstime.com