Resource Centre

Discover a wealth of knowledge and insights from the experts at StarFish Medical. Our Resource Centre offers product development tips, reviews of new and cutting-edge technologies, and in-depth articles on regulatory updates and compliance in medical device development.

-

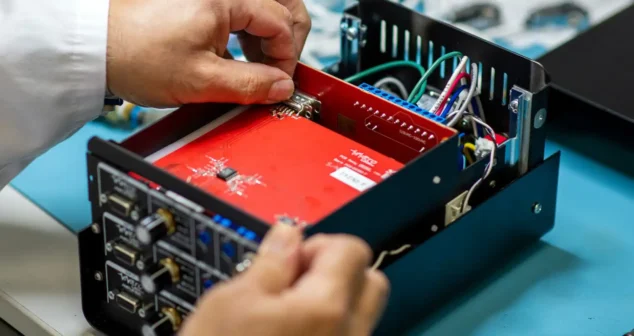

Your team is ready for design validation. The prototype performs well, test plans are in motion, and everything points to a smooth handoff to manufacturing. Then your partner calls with bad news: they can’t build the device as designed.

-

You’ve cleared the toughest engineering hurdles and proven your design works. Then, just as you prepare to scale, your contract manufacturer turns you down.

-

In Medtech, a successful exit isn’t just about having an innovative device, it’s about building a business that potential buyers and investors can clearly see a future in.

-

Being ready to build is not the same as being ready to scale. Successful market introduction requires manufacturing readiness that evolves alongside market readiness.

-

Ariana Wilson and Mark Drlik explore how teams can reduce the device development timeline without compromising quality or compliance.

-

Understanding medical device classifications is critical for compliance, risk management, and time-to-market success. Whether you’re designing a wearable sensor or a life-sustaining implant, knowing how your device fits into FDA Class 1, 2, or 3 categories is essential.

-

Delivering a drug to the right place at the right time can define the success of a therapy. Yet understanding delivery routes, devices, and technologies across the body can be complex.

-

This in-depth drug delivery strategy guide from StarFish Medical explores how to design, develop, and deliver breakthrough drug-device combination products.

-

Choosing the right design and development partner is one of the most critical decisions in bringing a medical device to market.