How Anodized Titanium Enhances Medical Devices with Structural Color

In this episode of MedDevice by Design, we explore the fascinating intersection of materials science and usability in medical device development. Mark Drlik and Ariana Wilson discuss how anodized titanium produces vibrant color without dyes, and how this visual property supports surgical safety, device differentiation, and biocompatibility.

Why Titanium Isn’t Really That Color

Anodized titanium appears colorful, but the hue is an optical illusion created by a thin oxide layer on the surface. As light reflects off both the titanium and its oxide coating, wavelengths interfere with each other to generate specific colors. The exact shade depends on the thickness of this layer, typically ranging from 30 to 55 nanometers. That’s about the size of a virus and smaller than a human cell.

Precision-Controlled Color Without Dyes

The anodization process occurs in a salt bath, where voltage is applied to submerge titanium acting as an anode. Oxygen builds up on the surface, thickening the oxide layer and shifting the visible color through the spectrum—from gold to green. However, due to how light interacts with the oxide, some colors like red are not achievable.

Design Advantages in MedTech

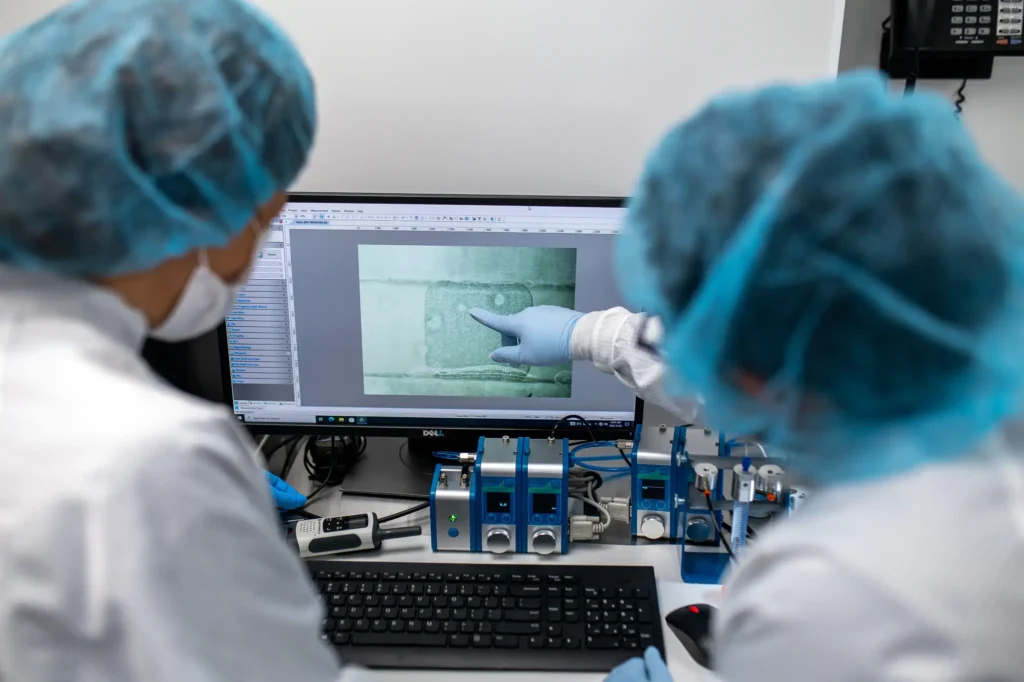

In surgical devices such as bone screws and drill plates, color coding improves usability and safety. Anodized titanium allows medical teams to quickly distinguish device sizes, anatomical sides (left vs. right), or instrument categories without relying on dyes. This is especially important in the operating room, where time and precision are critical.

Biocompatibility Benefits

Unlike anodized aluminum, which often requires additional dyes, anodized titanium achieves structural color naturally. This dye-free process enhances biocompatibility, making titanium a safer and more effective choice in many implantable or surgical applications.

Enjoying MedDevice by Design? Sign up to get new episodes sent to your inbox.

Related Resources

For manufacturers of novel devices that can make a significant impact to patient health, the goal of the program is to offer a path to streamlined and potentially faster market entry without sacrificing the rigour around ensuring safety and performance.

When I was starting out in medical devices, the discussion focused on the possibility of an internet of things and the promise of “big data” about everything.

With the release of ISO 14644-5:2025, Cleanrooms and associated controlled environments, Part 5: Operations, the standard places increased emphasis on operational discipline, human factors, and contamination control behaviour.

This article outlines the core elements of the PCCP framework, the types of modifications it applies to, and how the FDA expects manufacturers to use it in practice.