Medical Device Drop Testing in Action

Medical device drop testing helps ensure that products and packaging survive real-world handling. We demonstrate in-house drop testing on an actual device and its packaging using a custom-built drop tester.

From IEC Standards to Real-World Drops

While passing a standard test like IEC 60601-1 is a good first step, drop testing must also reflect real-world use. Devices get dropped repeatedly, often in uncontrolled settings. Packaging must protect the product all the way from warehouse to end user.

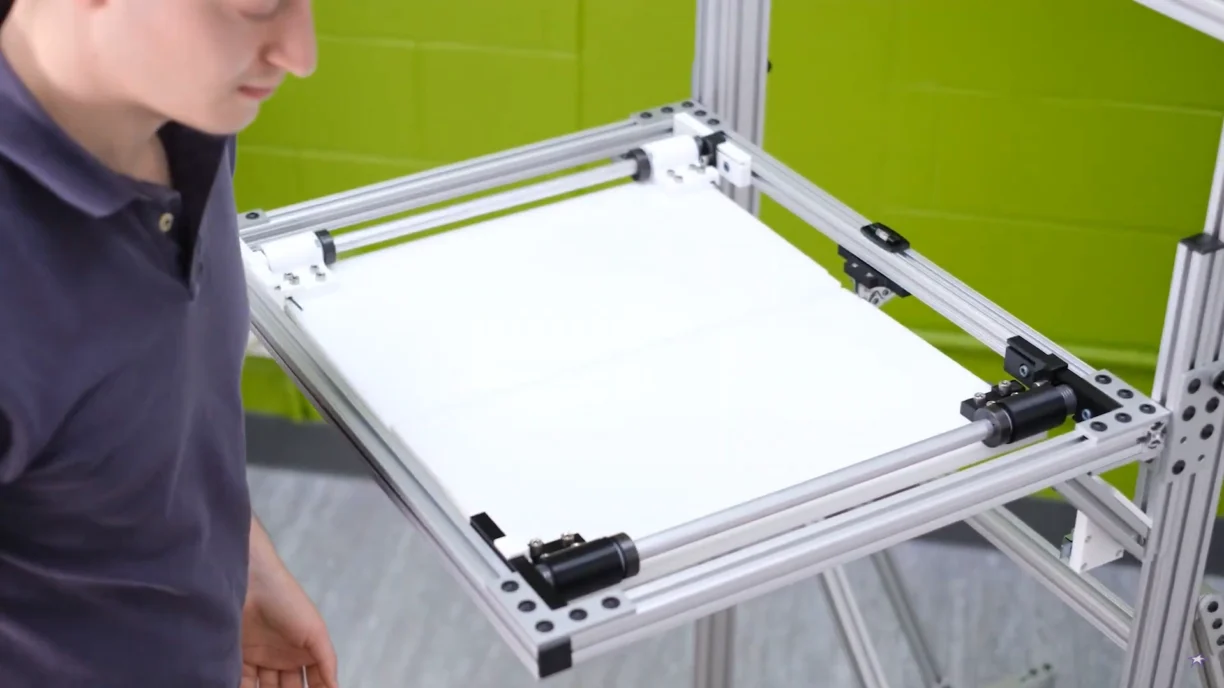

This episode shows how in-house testing setups let engineers explore failure modes before third-party verification. The drop tester featured includes adjustable doors, corner and edge supports, and surfaces for both hardwood and concrete impacts.

Testing Devices and Packaging

During testing, the team drops a medical device on various faces, edges, and corners. The results? Deformation, loose components, and internal rattling—clear signs of structural stress. Eventually, the device fails when dropped on its edge, offering valuable insights for redesign.

Next, they drop test a device package. Each face, edge, and corner is tested—including a downsized box for corner drop demos. A worst-case drop from double height shows whether the packaging holds up under extreme conditions.

Why In-House Drop Testing Matters

Medical device drop testing not only prepares teams for formal third-party tests but also helps identify weaknesses early. It saves time, protects users, and strengthens the final product. And yes—sometimes, it’s just fun to break things on purpose.

Related Resources

For manufacturers of novel devices that can make a significant impact to patient health, the goal of the program is to offer a path to streamlined and potentially faster market entry without sacrificing the rigour around ensuring safety and performance.

When I was starting out in medical devices, the discussion focused on the possibility of an internet of things and the promise of “big data” about everything.

With the release of ISO 14644-5:2025, Cleanrooms and associated controlled environments, Part 5: Operations, the standard places increased emphasis on operational discipline, human factors, and contamination control behaviour.

This article outlines the core elements of the PCCP framework, the types of modifications it applies to, and how the FDA expects manufacturers to use it in practice.