How Syringe Engineering Enables Precision at Scale

In this episode of Bio Break, Nick and Nigel dive into the fascinating world of syringe engineering. Despite costing just pennies, syringes pack an extraordinary amount of design and manufacturing complexity. From precision-molded barrels to breathably sealed packaging, these tools are more than meets the eye.

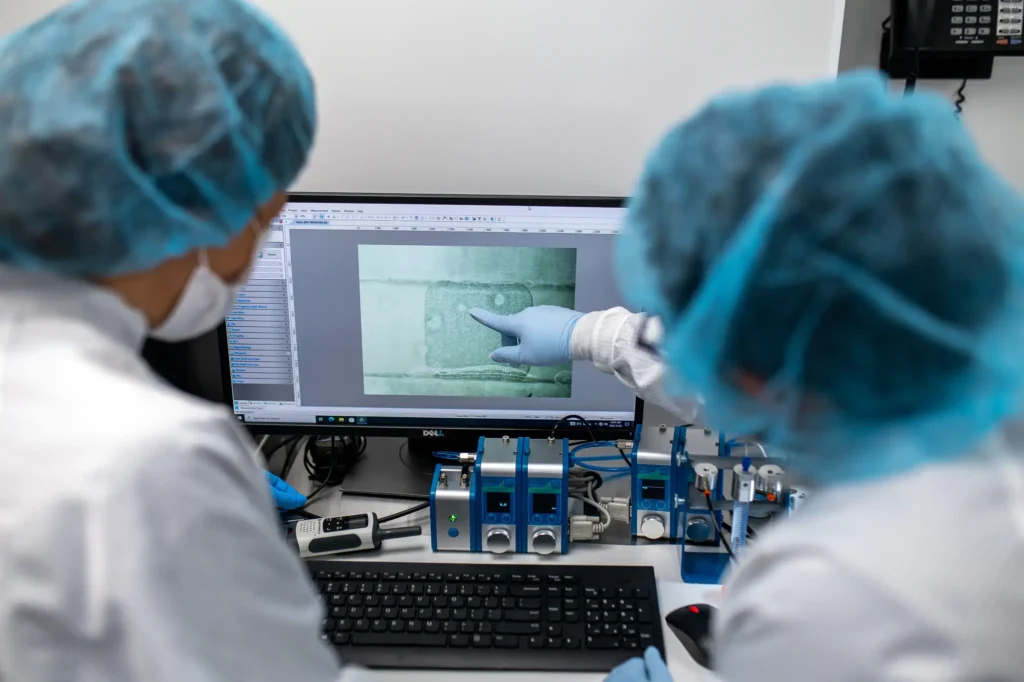

With billions produced each year, the design of syringes must balance cost, performance, and manufacturability. Syringes are typically injection molded, requiring precise draft angles and smooth interior finishes. Otherwise, even basic functionality—like forming a seal—can be compromised.

Nigel explains how even subtle design choices affect usability and accuracy. For instance, minimizing dead space in the barrel ensures accurate dosing, while tightly controlled extractables and pH levels support biocompatibility. The small ruler-like graduations on the side? They’re tested for microliter-level accuracy.

High-Volume Manufacturing and Packaging

To keep up with demand, manufacturers rely on high-throughput systems like form-and-seal machines. These automated lines assemble, seal, and label syringes with extreme efficiency. That means millions of sterile, ready-to-use devices can roll off the line daily—every one of them a testament to smart syringe engineering.

Why Syringe Design Still Matters

Even though syringes may not have a sharp “point,” they still make a sharp point about the value of thoughtful engineering in medtech. Nick and Nigel explore why this unsung device deserves a little more respect.

Curious about how these concepts apply to other drug delivery tools? Check out our episode on microneedles for transdermal delivery for another look at clever delivery methods.

Enjoying Bio Break? Sign up to get new episodes sent to your inbox.

Related Resources

For manufacturers of novel devices that can make a significant impact to patient health, the goal of the program is to offer a path to streamlined and potentially faster market entry without sacrificing the rigour around ensuring safety and performance.

When I was starting out in medical devices, the discussion focused on the possibility of an internet of things and the promise of “big data” about everything.

With the release of ISO 14644-5:2025, Cleanrooms and associated controlled environments, Part 5: Operations, the standard places increased emphasis on operational discipline, human factors, and contamination control behaviour.

This article outlines the core elements of the PCCP framework, the types of modifications it applies to, and how the FDA expects manufacturers to use it in practice.