Fluorescent Soil Load Test

Visualizing Cleaning Performance in Device Testing

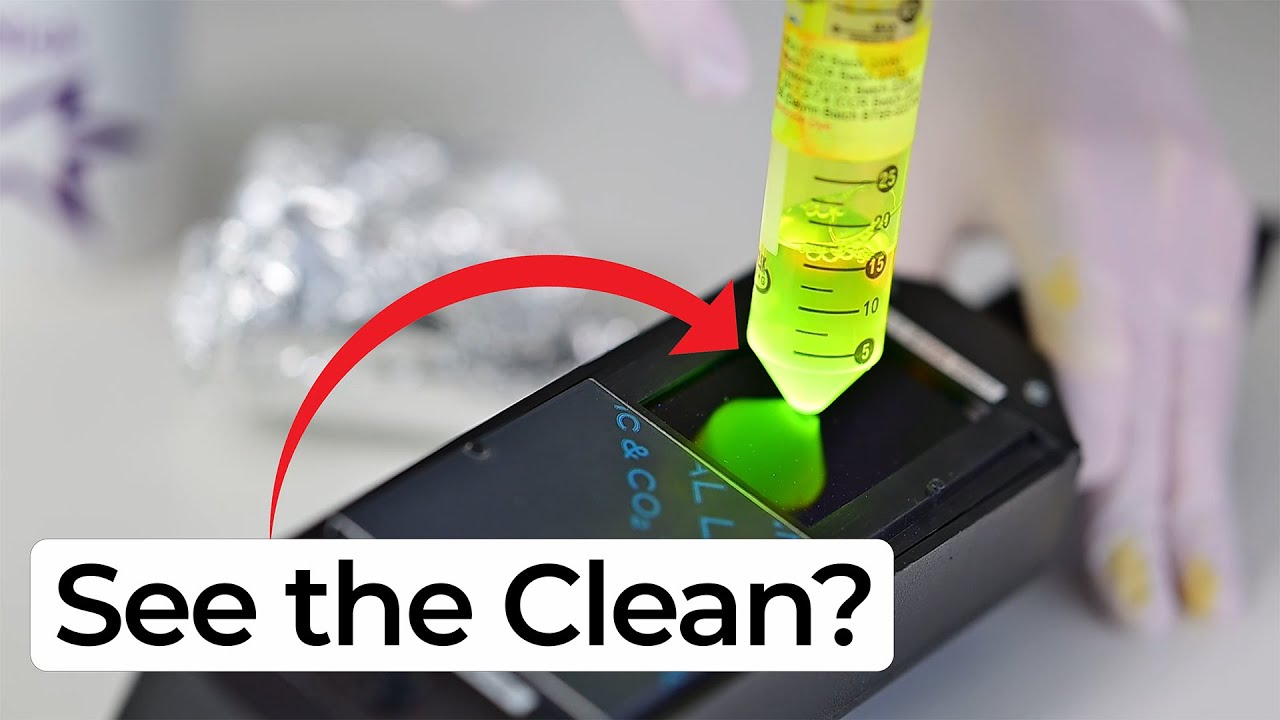

In this Bio Break episode, Nick Allan and Nigel Syrotuck explore a creative approach to visualizing cleaning validation using a fluorescent soil load. This method turns a standard cleaning solution into a glowing visualization tool, helping engineers assess how effectively a medical device can be cleaned.

They start with a standard, sterile artificial soil made from mucin and bovine serum albumin. This mixture mimics real-world contamination and is commonly used in cleaning validation tests. The challenge, however, is that the normal soil load is nearly invisible on surfaces, making it difficult to see where residue remains after cleaning.

A Bright Twist on Standard Testing

To make the soil load visible, the team at StarFish Medical modified the mixture by adding fluorescein, a compound that emits light under UV exposure. When illuminated, the fluorescent soil load glows bright orange, highlighting even small traces left on a surface. This allows engineers to wipe, rinse, and immediately visualize their cleaning results without complex instrumentation.

Using this technique, teams can quickly iterate on device cleaning designs, evaluate surface geometry, and confirm whether their cleaning approach is working effectively. The result is a simple, visual method that accelerates testing and reduces uncertainty during early product development.

Simple Tools, Big Insights

A standard UV light is all that’s needed to activate the glow, turning a simple cleaning test into a clear visual experiment. As Nick demonstrates in the episode, the bright fluorescence makes it easy to see success or missed spots, providing rapid feedback for design improvements.

This fluorescent cleaning test reflects StarFish Medical’s commitment to hands-on innovation, where small laboratory adjustments lead to meaningful process insights.

Enjoying Bio Break? Sign up to get new episodes sent to your inbox.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.