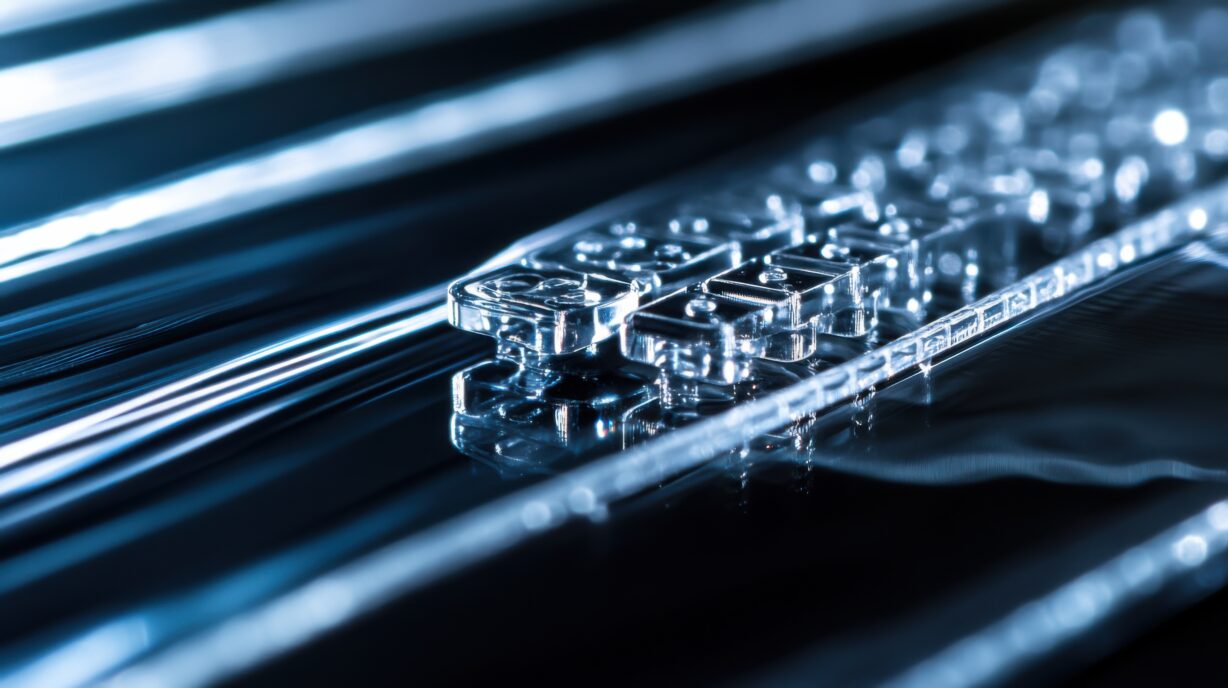

eGuide to Microfluidics Device Development

This paper offers insights and case studies in designing and producing a reliable microfluidic device, then taking it through clinical testing to market. It highlights steps for testing device performance (part of regulatory compliance) and setting suitable acceptance criteria for successful market introduction.

Despite the compelling advantages of microfluidics, most commercial products are still in the developmental stage. Commercialization challenges include integration into existing laboratory processes, developing appropriate assembly processes for micro features, and producing at scale within required tolerances and reliability.

Finished microfluidic devices may appear simple but designing and producing them requires an interdisciplinary team of engineers, scientists, medical practitioners. Product development teams often include members with expertise in assay development, device design and modeling fluidics, materials, optics, and sensors.

Producing microfluidic products reliably at -scale can be challenging. Microfluidic devices must be manufactured in a highly repeatable process at a high yield (particularly in medical applications).

Microfluidic devices are versatile platforms for the variety of applications. Once the requirements of the intended application are identified, the product development process starts. Several factors must be considered to ensure that a reliable manufacturing process is developed 7. Learn more about the 10 considerations to ensure microfluidic device manufacturability.

Using Microfluidic Development Tools in Medical Devices

eGuide to Microfluidics Device Development

Discover the Benefits of Enterprise Partnerships and Working with StarFish Medical.