Integrating Microfluidics into Biomanufacturing

Enabling Features for Biomanufacturing Applications

Integrating microfluidics into biomanufacturing lines is a very exciting concept. Microfluidics has the ability to miniaturize manufacturing processes such as cell culture, classification, droplet generation, encapsulation, mixing, and more.

Microfluidics offer more precise control of the microenvironmental conditions, feeding and changing culture media, and characterization of the end products.

Manufactured bioproducts utilize raw biological materials to produce commercially important components and molecules for use in medicines and other potential applications (i.e., food, drugs, and vaccines). Common sources of these raw materials include bodily fluids (i.e., blood), cultures of microbes, animal cells, or plant cells. The cells used during the production may have been naturally occurring or derived from genetic materials.

Bio manufactured products for medical use could be intermediate or end-products such as cells, biomolecules, process enzymes, amino acids, biopharmaceuticals, antibiotics, proteins, growth factors, monoclonal antibodies, and vaccines. The global bio-based materials market size is expected to reach about USD 87 Billion by 2026, at a CAGR of 26.5%.

Importance of integrating microfluidics into biomanufacturing

Microfluidics technologies are proven to be potentially useful for cell biology and biomanufacturing.

In general, microfluidics can miniaturize and improve existing macro infrastructure and manufacturing protocols by taking advantage of the possibility of parallel processing. It is very important to note that microfluidic devices are designed to be closed systems that can control the cellular microenvironment; hence, it makes them ideally suited for the interaction between the cell’s environment and cellular behavior. With this feature, microfluidic cartridges and systems can be designed to enable high-throughput cell, biomolecule, or biologic production from a single microfluidic bioreactor to a massive line of miniaturized bioreactors.

The most common concept is an inline microfluidic bioreactor for cell line selection and process characterization. In this concept, culture conditions could be optimized providing parallel processes in small volumes, rather than in a large batch of production. It facilitates quality control in identically sized, multi-parallel bioreactors which allow the user to monitor the system and gather more process information quickly and efficiently.

Another very important aspect is process optimization. Small production runs can be done in a single microfluidic line to evaluate the process parameters, such as temperature, feeding, media composition, gas components and composition, and raw material densities, without using a large volume of reagents. Small wasted raw materials and minimal production overhead are much better than discarding volumes of inputs and significant manpower resources in a failed run.

In microfluidics, a conducive microenvironment could be created in micro-macro channels or even in the reservoirs thus allowing precise control of liquid composition at a sub-cellular level. Optimization can be implemented by automated media changes and temperature control in the chamber.

A microfluidics-enabled biomanufacturing set-up can use samples and reagents in volumes at the nanoliter levels. Microfluidic systems can run and be programmed to generate many different specific conditions and facilitate the implementation of numerous analytical operations as the baseline for future large-scale integration.

Another exciting development is in nano-micro encapsulation. A biomaterial can be enclosed by biocompatible materials for a variety of research, pharmaceutical, and medical applications. There are microfluidic devices that are used for cell and reagent encapsulation, particle generation, tissue bioprinting and other constructs. At the back end, microfluidics can be designed to perform cell or particle sorting and classification to increase the purity and quality of the end products.

Most importantly, microfluidics enables efficient control of production parameters which will serve as a reference before engaging in a large-scale integration and mass production.

Enabling features of microfluidics for biomanufacturing

Microfluidics open numerous new opportunities for biomanufacturing. Here are the top four enabling features for biomanufacturing applications.

1. Small cell culture volumes can be scaled up by in-line parallel systems.

This is crucial if the raw materials are scarce and expensive. Microfluidics can handle nanoliter to microliter volumes and can control microenvironments for optimum cell growth and production. For biologists and bioprocess engineers, this is a powerful capability in managing precious cell lines, or for drug discovery purposes, wherein the drugs or biologics could pass through the single cells in the channels or reservoirs to evaluate cell responses.

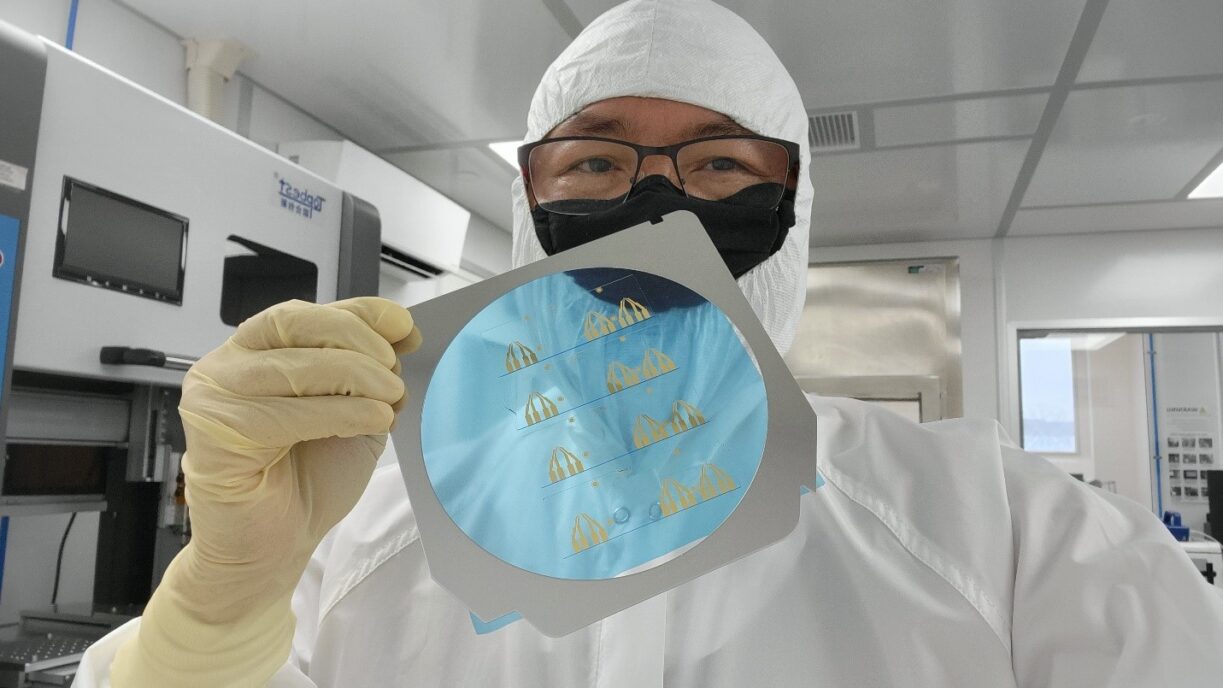

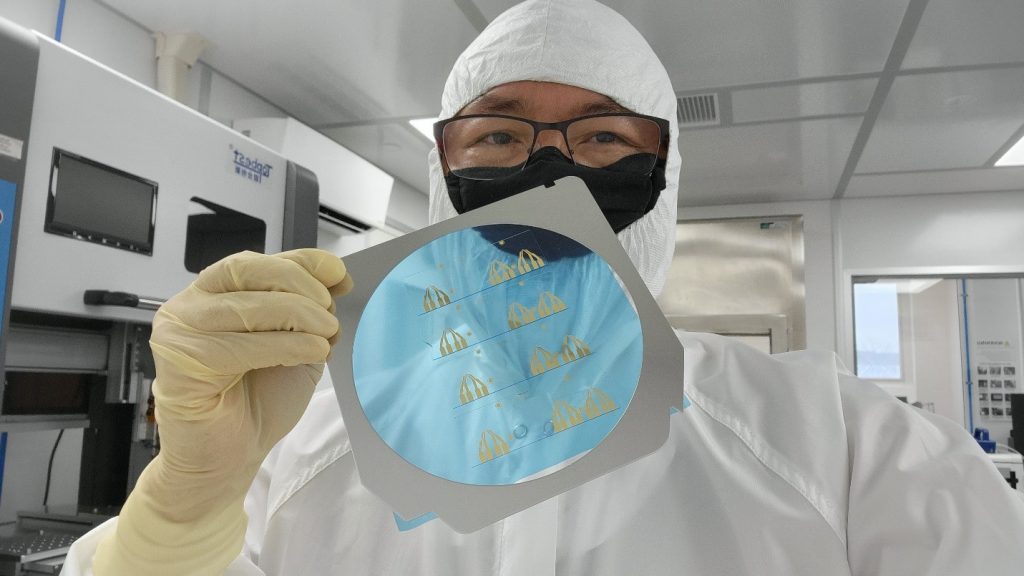

For example, we developed a microfluidic device with built-in nanoliter chambers for cell culture with an integrated temperature sensor and automated media renewal. We expanded this device to an array of 96 chambers with controllable culture conditions to maintain cell health and viability. This feature will allow the production of specific cell lines in a small footprint and can be scaled up into in-line large volume production.

Discover the Benefits of Enterprise Partnerships and Working with StarFish Medical.

2. Control micro-environmental conditions for optimal cell production and end-product quality

Environmental control (including gas composition and temperature), medium renewal, and feeding are other key parameters for long-term cell culture and production. As in large-scale biomanufacturing for cell lines or biomolecules, these parameters can be controlled automatically for quality and better yield of the final product.

Examples include microfluidic devices with an automated pumping system (i.e., pneumatic, or peristaltic pump) that renews media through the feeding channel and the channel containing cells. There are also microfluidic devices in which the cells are trapped using specifically designed channels wherein the media can easily flow around the trapped cells. In other designs, some devices flow medium through the primary channel to allow nutrients to pass through a particular membrane to the secondary channel containing cell cultures without disturbing cells with flow.

In cell culture and cell production, conducive microenvironment control during the process ensures excellent cell quality and steady growth in a particular cell line.

3. Generate different sizes of droplets and particles for encapsulation, particle mixing, and coating for bioprinting and biomaterial production

Microfluidics has demonstrated the ability to produce droplets in the nano to the micron size range. Droplet sizes can be controlled, and generation speed can be managed. Single cells can be allowed to flow in a channel with automatic encapsulation occurring at the same flow. There are microfluidic devices that are designed as droplet generators. These devices can produce thousands of droplets with embedded cells.

In some of our projects, we developed and designed microfluidic devices for single cells, with patterned features that facilitate the single-cell flow. The ability to flow a single cell or biomaterial is important in encapsulation and coating. These encapsulated end products can be used as raw materials for 3D tissue printing or drug development purposes.

4. Enable testing and characterization of bioproducts for quality control

Microfluidic devices are designed to be disposable and can be produced cheaply in large quantities which are perfect for small to pilot-scale biomanufacturing and testing.

Microfluidic devices are used for quality control purposes wherein samples can be introduced to the device for characterization and testing. A typical example is a device that we developed in-house for cell characterization, sorting, and classification. The intent is to sort the cells, or any bio-manufactured product for grading and quality control while keeping a consistent throughput on the production line. Microfluidic devices with integrated sensors can be used to monitor processes and facilitate quality inspection. These devices may significantly increase the batch yield and reduce processing time.

Summary

Utilizing microfluidic technology for biomanufacturing is an advancement in developing or testing new biomolecules or biologics for a variety of medical uses and therapies. One of the promising microfluidics applications for biomanufacturing is the production of cell lines in a parallel system, utilizing the ability of microfluidics to manage small volumes at the level of a single cell.

Furthermore, the ability of microfluidics to produce tiny droplets and nano- or micro-spheres (beads), as well as the ability to encapsulate, will pave the way to producing an efficient drug delivery system that can control its release in the body.

Similarly, the production of tiny, encapsulated bubbles using microfluidics can be used for preserving cells. This ability could be very useful for 3D bioprinting of tissues and organs in the future.

Microfluidics technologies and devices being designed and built today will support and improve biomanufacturing processes. Indeed, it’s a perfect match.

References:

- Aranda Hernandez J, Heuer C, Bahnemann J, Szita N. Microfluidic Devices as Process Development Tools for Cellular Therapy Manufacturing. Adv Biochem Eng Biotechnol. 2021 Aug 20. DOI: 10.1007/10_2021_169. Epub ahead of print. PMID: 34410457.

- John Conner, Don Wuchterl, Maria Lopez, Bill Minshall, Rabi Prusti, Dave Boclair, Jay Peterson, Chris Allen, Chapter 26 – The Biomanufacturing of Biotechnology Products, Biotechnology Entrepreneurship, Academic Press, 2014, Pages 351-385, ISBN 9780124047303.

- Laura Wood. 2022, January 14. Global Next-Generation Biomanufacturing Market Report 2021-2031: Growing Trend among Biomanufacturing Vendors to Integrate Automation Technologies.

- Charles Heise, Mark Brower. 2021 Report. Biomanufacturing Technology Roadmap: continuous Downstream Processing for Biomanufacturing: Industry Review. BioPhorum.com

- Sara M Bjork, Haakan N Joensson, Microfluidics for cell factory and bioprocess development, Current Opinion in Biotechnology, Volume 55, 2019, Pages 95-102, ISSN 0958-1669.

Images: StarFish Medical

Lorenzo Gutierrez is the StarFish Medical Microfluidics Manager. Lorenzo has extensive experience translating point of care assays to microfluidic cartridges. His microfluidics portfolio includes developing a polyvalence instrument for early infant diagnostics at Chipcare.