ISO 14644-5:2025 Cleanroom Operations Explained

TL;DR

- ISO 14644-5:2025 shifts cleanroom focus from design to disciplined operations.

- Human behaviour is the dominant contamination risk.

- The standard reinforces risk-based operational controls aligned with quality systems.

- Gowning, cleaning, and maintenance are treated as controlled processes.

- Cleanroom operational models require tailored controls.

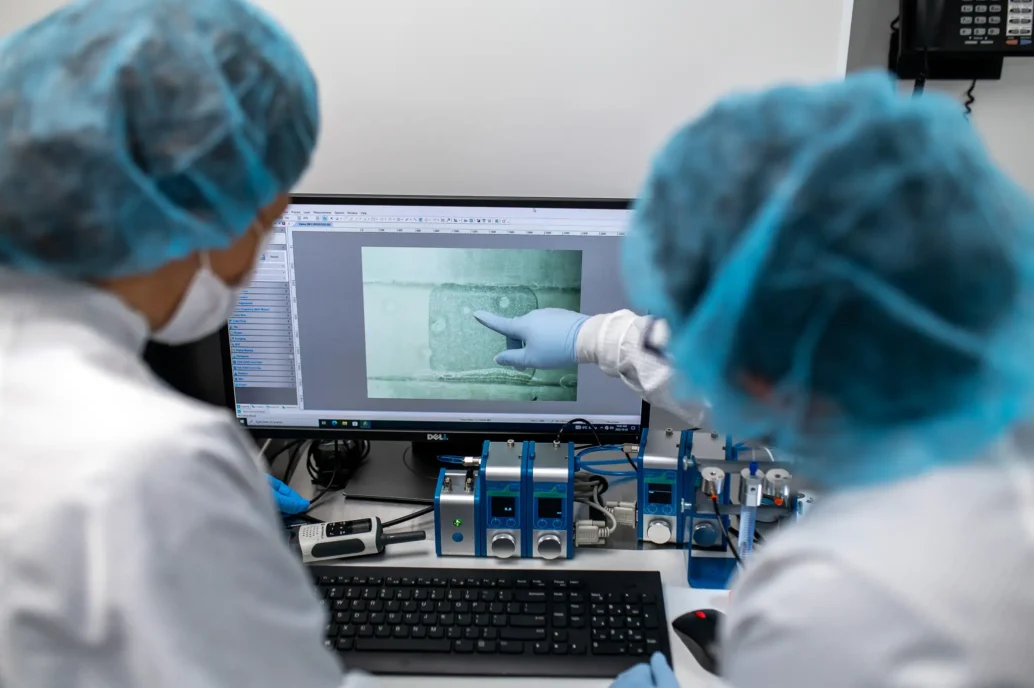

Cleanroom performance is no longer defined solely by air cleanliness classification. With the release of ISO 14644-5:2025, Cleanrooms and associated controlled environments, Part 5: Operations, the standard places increased emphasis on operational discipline, human factors, and contamination control behaviour. This update reinforces a long-standing reality: even the best-designed cleanroom can fail if operational controls are weak.

Medical devices often require very low particulate environments, such as ISO Class 7 or 8, for activities like final assembly or primary packaging. Failures in operational discipline can have serious consequences, including latent contamination that evades inspection, product recalls, and regulatory action. A cleanroom’s technical classification is only as reliable as the practices that maintain it.

For organizations operating cleanrooms in medical device manufacturing, understanding and implementing ISO 14644-5:2025 is essential to maintaining control, consistency, and audit readiness.

What ISO 14644-5:2025 Covers

ISO 14644-5, Cleanrooms and associated controlled environments, Part 5: Operations, provides guidance on how cleanrooms should be operated and maintained to preserve their classified state.

Unlike other parts of the ISO 14644 series that focus on design, testing, or classification, Part 5 addresses day-to-day operational practices, including:

- Personnel behaviour and training

- Gowning systems

- Material and equipment flow

- Cleaning and disinfection

- Maintenance activities

- Operational documentation

The 2025 revision aligns more closely with modern risk-based quality systems and global regulatory expectations, with an increased focus on the Operations Control Programme (OCP). The OCP is a documented suite of procedures, training, monitoring, and governance that keeps a cleanroom performing as designed.

Key Operational Changes in ISO 14644-5:2025

Stronger Focus on Human Factors

Personnel remain the largest source of contamination in cleanrooms. The updated standard emphasizes:

- Defined cleanroom behaviours, including movement and interactions

- Competency-based training and requalification

- Minimizing unnecessary interventions

- Behavioural controls tied directly to contamination risk

This reflects a shift from training completed to training effectiveness demonstrated.

Risk-Based Operational Controls

ISO 14644-5:2025 promotes a risk-based approach to cleanroom operations, consistent with ISO 13485 and GMP principles.

Organizations are encouraged to:

- Assess contamination risks by activity, not just by room classification

- Adjust controls based on product sensitivity and process criticality

- Document the rationale for operational decisions

This approach supports flexibility while maintaining control.

Enhanced Guidance on Gowning Systems

The standard reinforces the importance of appropriate gowning selection and control, including:

- Matching gowning materials to cleanroom class and activity

- Defined gowning procedures and sequencing

- Controlled storage, handling, laundering, and disposal

- Periodic review of gowning effectiveness

Gowning is positioned as a critical contamination control barrier, not a formality.

Material and Equipment Transfer Controls

ISO 14644-5:2025 provides clearer expectations for:

- Segregation of clean and non-clean items

- Transfer procedures that prevent contamination ingress

- Cleaning and disinfection of tools and equipment

- Flow paths that reduce cross-contamination

Material movement is treated as an operational risk point that requires documented controls.

Cleaning and Disinfection as a Controlled Process

Cleaning is no longer viewed as a routine task, but as an evaluated and monitored operation.

The standard emphasizes:

- Defined cleaning frequencies and methods

- Selection of appropriate cleaning agents, including compatibility with equipment, tools, and surfaces

- Rotation of disinfectants where applicable

- Training and qualification of cleaning personnel

- Records that demonstrate execution and effectiveness

Maintenance and Intervention Controls

Maintenance activities pose elevated contamination risk. ISO 14644-5:2025 highlights:

- Planning and authorization of interventions

- Post-maintenance cleaning and verification

- Temporary controls during maintenance

- Documentation of deviations and recovery actions

These expectations support sustained cleanroom performance over time.

Aligning ISO 14644-5:2025 with Your Quality System

ISO 14644-5:2025 integrates seamlessly with established quality systems by reinforcing:

- Clear, controlled SOPs for cleanroom operations

- Defined roles and responsibilities

- Training records and competency assessments

- Deviation handling and corrective actions

- Change management for operational updates

Even if not directly cited in regulatory submissions, operational compliance may be scrutinized during audits and inspections..

Continuous Production vs. Project -Based Cleanroom Use

Cleanroom usage is not one-size-fits-all. Two common operational models in medical device facilities are continuous production operations and project-based cleanroom use.

Continuous Production Operations

Facilities that run continuously, such as high-volume assembly lines for catheters or implants, face distinct operational challenges, including:

- Steady-state discipline, where Processes, gowning practices, and material flows must be repeatable with minimal variation

- Routine cleaning intervals scheduled to maintain quality without interrupting production

- Continuous monitoring using real-time environmental systems for trend analysis and alerts

- Personnel scheduling that accounts for fatigue, coverage, and variability

For continuous operations, the Operations Control Programme becomes a living program, with frequent review of control points, trend data, and change control activities.

Project-Based Cleanroom Use

Cleanrooms dedicated to project-specific activities, such as prototyping, regulatory submission batches, or pilot runs, have different operational priorities, including:

- Flexible procedures that accommodate varied tasks while maintaining contamination control logic

- Entry and exit protocols for Materials and prototypes, supported by quarantine, decontamination, and documentation processes

- Training surge requirements due to ad hoc operator assignments

- Start and stop impact planning to assess and mitigate project-specific risks

Both operational models benefit from the risk-based approach embedded in ISO 14644-5:2025. The goal is to identify contamination risks tied to human activity, equipment, or material flow, then mitigate and monitor those risks systematically.

Why ISO 14644-5:2025 Matters for Medical Device Manufacturers

For medical device organizations, cleanroom operations directly impact:

- Product quality and patient safety

- Environmental monitoring trends

- Inspection outcomes

- Operational efficiency and deviation rates

Adopting ISO 14644-5:2025 demonstrates a mature, proactive approach to contamination control and operational excellence.

Conclusion

ISO 14644-5:2025 is a strategic framework that bridges technical cleanroom design and disciplined operations. For medical device manufacturers, this means embedding quality and contamination control into everyday cleanroom practices, whether the space supports continuous production or project-based work. The result is more consistent performance, stronger regulatory confidence, and fewer surprises during audits.

ISO 14644-5:2025 Cleanrooms and associated controlled environments – Part 5: Operations

As a member of the QA/RA team, Bhavyashree is dedicated to ensuring product quality and compliance. With a keen eye for detail, she strives for excellence within the field of quality assurance and regulatory affairs.

Images: Adobe Stock

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.