Five Applications Using Microfluidic Machine Learning

Microfluidics is a powerful tool on its own, but over the past years, the combination of microfluidics and Machine Learning (ML) has enabled microfluidic technologies to push into new areas and applications. Microfluidics is a fluid handling technique which takes place inside micro-channels or pathways using nano/microliter volumes. It has been used in many applications particularly in miniaturizing laboratory processes and procedures.

Machine Learning covers a broad spectrum of activities such as algorithm development, predictive modelling, classification and learning, neural networks and others. In order to train the algorithms, they need to be fed large data sets (training data) to build models and make predictions or decisions without being explicitly programmed to do so.

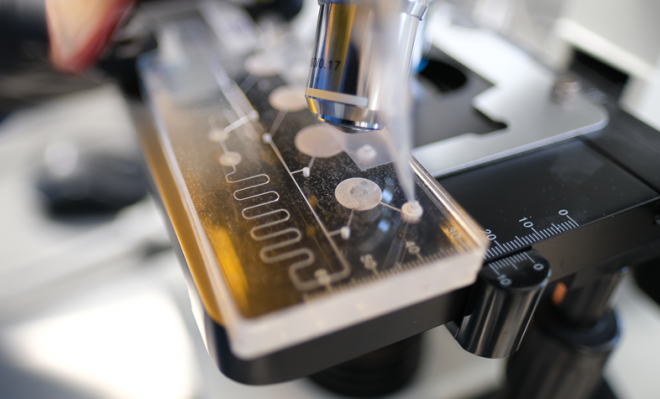

For instance, a microfluidic point-of-care diagnostic instrument for detecting diseases by classifying biomarkers in blood, urine, saliva and sweat, generates huge quantities of images that need to be analyzed in a short period of time. As the samples pass through the detection area in a microfluidic cartridge, the sensor captures data, and this information is processed in an internal processor or computer. Analyzing these large data sets would not be possible without ML thus enabling the use of microfluidics in rapid disease diagnosis.

The microfluidic cartridge by itself does not generate data. Instead, the cartridge facilitates sample processing and implementation of assay protocols inside microfluidic channels and reservoirs. Furthermore, microfluidics is used to prepare the analytes for detection and quantification. Depending on the application, various detectors can be used (i.e., camera or photomultiplier tube (PMT), electronic sensors and biosensors) to obtain the target results after which the data is collected inside internal processors or by using cloud platforms. Cloud platforms can have the advantage of being linked to super computers to allow for faster processing and storage of reference data sets.

In general, Machine Learning in microfluidics is used in protocol processes, optical detection, and image sorting, classification and pattern recognition, large data analysis and comparison, forecasting and prediction. The accuracy and efficacy of the algorithms depends on the training data; the more data used in the process the more accurate the results will be. Importantly, software developers can also use Machine Learning to create an algorithm that can be ‘locked’ so that its function does not change in the field. This is critical for medical devices that have to clear regulatory submissions and cannot be changed without new clinical validation studies.

1. Microfluidic cell sorter and classifier

In biology, cell sorting and classification are traditionally implemented by taking pictures under the microscope with sample labeling (i.e. tagging with fluorescent materials) and different light sources. These images are then analyzed by counting and classifying the characteristics of each specific cell. In cell culture laboratories, cells are often counted and classified in real-time using microscope and manually operated counters. This procedure is very tedious and subject to human errors. For example, blood cells size ranges from 2-10 um in diameter (diameter of human hair is around 70 um). In 1 µL of blood from a healthy man, there are around 4 to 6 million cells, and around 4 to 5 million cells from a healthy woman. Characterizing these cells in 20 minutes, requires interrogating cells at the rate of 5000 cells per seconds. That’s a lot of data and images to be reviewed and analyzed.

Microfluidics has revolutionized this process in small, easy-to-use and disposable cartridges. Cells are loaded in the cartridge and, using a reader, are automatically counted and classified. This platform enables new approaches in the diagnosis of diseases, single-cell characterization and analysis, cell imaging and pathogen detections. However, these advances produce large volumes of data and images to analyze. Machine Learning enables live cell sorting, classification and visualization by automating data analysis. The most common platform in which ML enables microfluidics to automate cell sorting is fluorescence-activated cell sorting. Here, fluorescent labels are used to identify desired cells within a heterogeneous population. Another platform is label-free cell sorting which relies primarily on forward- and side-scattered signals in the absence of fluorescence labels. These image-based cell sorting systems utilize microfluidic or microarray platforms, each having unique characteristics and applications. In both techniques, algorithms that are developed by ML play a critical role in the sorting and classification of live cells.

2. Microfluidic enabled flow cytometer

Flow cytometry is a method used to detect and measure physical and chemical characteristics of a population of cells or particles as it flows through the detection tube. Its use includes cell counting, sorting, classification and detection.

A microfluidics-enabled flow cytometer is a cartridge type cytometer wherein the cells are loaded and are allowed to flow in a channel within the same cartridge. The cartridge is disposable and is used to prepare the sample to be interrogated. The cytometer then uses image acquisition to collect data (i.e., images or electrical features). Data acquisition is obtained using a high-performance graphics processing unit (GPU) and an on-board computer in the instrument. The data is analyzed using Machine Learning algorithms at a high processing rate to present a decision and quantitative prediction.

In one of our projects, we designed and fabricated a microfluidic flow cytometer cartridge to detect fluorescence indicative of the response to a specific disease of interest. In that particular microfluidic device, a CMOS camera was used to capture images at 30 frames per second as labeled cells flowed along the interrogation channel. One of the challenges we encountered was the ability for the software to accurately track the moving cells while controlling the fluid flow rates.

A Machine Learning algorithm was implemented to simultaneously track the moving cells and predict its next location as we classified the cell. The algorithm was trained using different samples, scenarios and cell features (such as morphology, size, characteristics and fluorescence intensity) as the cell moved along the channel. Data analysis was made in real time and initiated a triggering mechanism to determine the number of targets labeled cells and tracked it within the microfluidic channel. A sequence of around 54,000 images produced over 30 minutes resulted in a relatively large set of data to be analyzed. Traditionally, it would take us 2-3 hours to review and analyze the data to come up with a diagnosis. However, with a trained Machine Learning algorithm, we obtained results in less than 20 minutes.

3. Microfluidic enabled particle identifier

Similar to a microfluidic flow cytometer, this microfluidic cartridge includes channels and reservoirs as well as an actuator in a consumable format. The actuator moves the fluids along the channels. The platform can analyze and characterize large numbers of suspended microparticles or microspheres sequentially, while flowing at high speed through a measuring device within the channel. These microparticles (also known as beads) are in the range of a few microns in diameter (0.5 µm – 5 µm). However, bead sizes used in nucleic applications are at the nanometer range.

These beads can be either magnetic or non-magnetic, hydrophobic or hydrophilic, and reactive molecules can be added to the bead surface (functionalization) depending on the chemistry requirement of the target assay protocol. Hydrophilic microparticles, for example, allow gentle absorption and coupling of molecules, keeping the functional activities of proteins intact after immobilization. Hydrophobic microparticles are used for optimal coupling of antibodies for purification processes. Typically, 0.5 µm – 1 µm microparticles are used to capture proteins, nucleic acids and other bio-molecules, while a larger size (say 4.5 µm) is well suited for cells.

As these microparticles move inside the microfluidic channel or fluidic paths, the microparticles are illuminated – usually by a laser or high-power LED that is beamed to the cartridge interrogation zone, and the corresponding forward- and/or side-scattering intensities are measured, together with the fluorescence emission.

By design, the microfluidic cartridge allows the use of fluorescent labels on these microparticles to discriminate between different particle populations at high throughput (up to around 100,000 particles). To enable accurate and relatively fast analysis, additional sensor components are employed, such as by detecting electrical impedance and a fast-imaging camera coupled with a Machine Learning algorithm. The Machine Learning algorithm is very useful in managing huge sets of data using different classifiers and features recognitions.

Moreover, Machine Learning in microfluidics, when used on high throughput and multiplexed assays, facilitates implementation (i.e., fluid handling and protocol sequencing), detection of particles with target analytes, and analysis of large samples making the workflow more efficient and cost effective.

4. Microfluidic in digital format

Another interesting application of Machine Learning is in digital microfluidics (DMF). Digital microfluidics is a technology that handles and manipulates discrete droplets based on the principle of electrowetting on dielectric. In handling droplets, the local contact angle of an aqueous droplet is changed by the application of an electric potential on an electrode underneath a dielectric material. Subsequently, the discrete droplets are manipulated on the hydrophobic substrate due to spatial control of the contact angle through electric potentials. In contrast, with other microfluidic technologies that uses channels, digital microfluidics has no channels in moving and manipulating fluids. Instead, fluids sit on top of electrodes and move dependent on pre-programed direction of movements.

Machine Learning is applied in predicting the droplet movement speed, directions and processes in combination with changes to the electrical potentials of each electrode. Assay protocols can be implemented by programming various steps as the digital microfluidic platform performs the procedure. DMF can also be used as flow cytometry to analyze cells as well as microparticles suspended in fluids. Imaging can be done in the platform to acquire a huge amount of data. Machine Learning algorithms can be employed in predicting fluidic manipulations and to analyze data, thus improving throughput and reliability, especially in the context of complex assay protocols.

5. Microfluidic cancer cells diagnostic tool

Detection of circulating tumor cells (CTC) is yet another application of Machine Learning in microfluidics. The ability to identify CTC holds promise for early detection of primary cancer or metastasis. Using microfluidic as a sample preparation platform, blood cells can be aligned in a single narrow channel allowing the imaging system to scan all cells passing along the channel at a high flow rate. The detector module excites the cell with a specific wavelength and the emitted light is collected after passing through a filter. An image capture device (i.e camera, PMT) collects the data for analysis. A Machine Learning algorithm can be created to detect features and classify the data accordingly. For large volume of images, a Machine Learning algorithm using neural networks that takes less than a few milliseconds is employed to classify the cells – fast enough to provide a decision to a cell sorter for real-time separation of individual target cancer cells. This technique has been demonstrated in many research publications and commercial units.

Summary

Microfluidics permit the automated process of fluids manipulation at a microscale level with high precision, enabling the generation of large, multidimensional datasets. Machine Learning provides powerful predictive tools with the ability to learn from data. The analysis of microfluidic data via Machine Learning has been applied in a variety of contexts, achieving impressive results. As presented, Microfluidic Machine Learning is a valuable tool in facilitating control, image capture, analysis and predictive results for many microfluidic enable applications.

For more information on Machine Learning, please refer to this link.

Image: StarFish Medical – Bioservices

Lorenzo Gutierrez is the StarFish Medical Microfluidics Manager. Lorenzo has extensive experience translating point of care assays to microfluidic cartridges. His microfluidics portfolio includes developing a polyvalence instrument for early infant diagnostics at Chipcare.