Fluorescent Protein Assay Testing in Medical Devices

Understanding the Fluorescent Protein Assay

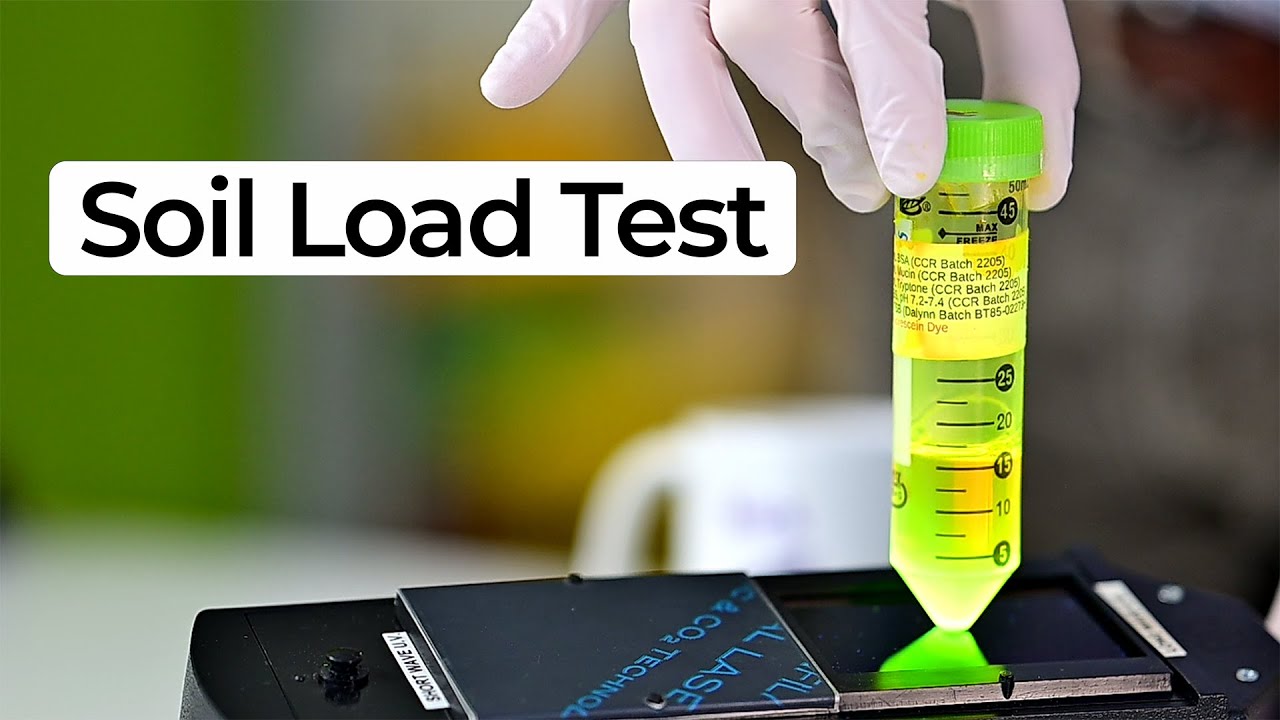

In this Bio Break episode, Nick Allan and Nigel Syrotuck explain how a fluorescent protein assay helps engineers measure contamination and cleaning performance in medical devices. At StarFish Medical, the team develops controlled soil mixtures that safely simulate bodily fluids. These “artificial soil loads” allow precise testing of how effectively a device can resist or release contaminants.

The Science Behind Soil Load Visualization

To make invisible residues measurable, fluorescent dyes are introduced into the protein-based soil. Nick describes how common assays such as the Bradford Comassi and BCA assay use chemical reactions to bind with protein molecules. When exposed to certain light wavelengths, these compounds absorb and emit light differently, creating measurable fluorescence. This allows researchers to see exactly how much protein remains after cleaning.

Quantifying Cleaning Performance in MedTech

By using fluorescence to detect trace contamination, engineers can go beyond visual inspection. As Nigel and Nick discuss, results compared against a standard curve reveal how well a device resists soil accumulation or supports effective cleaning. These insights guide medical device developers toward safer, more reliable designs that meet regulatory expectations.

Enjoying Bio Break? Sign up to get new episodes sent to your inbox.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.

Nick and Nigel walk through how indirect ELISA works, why it uses two antibodies instead of one, and when this approach makes the most sense in real diagnostic workflows.