Medical Device Drop Testing in Action

Medical device drop testing helps ensure that products and packaging survive real-world handling. We demonstrate in-house drop testing on an actual device and its packaging using a custom-built drop tester.

From IEC Standards to Real-World Drops

While passing a standard test like IEC 60601-1 is a good first step, drop testing must also reflect real-world use. Devices get dropped repeatedly, often in uncontrolled settings. Packaging must protect the product all the way from warehouse to end user.

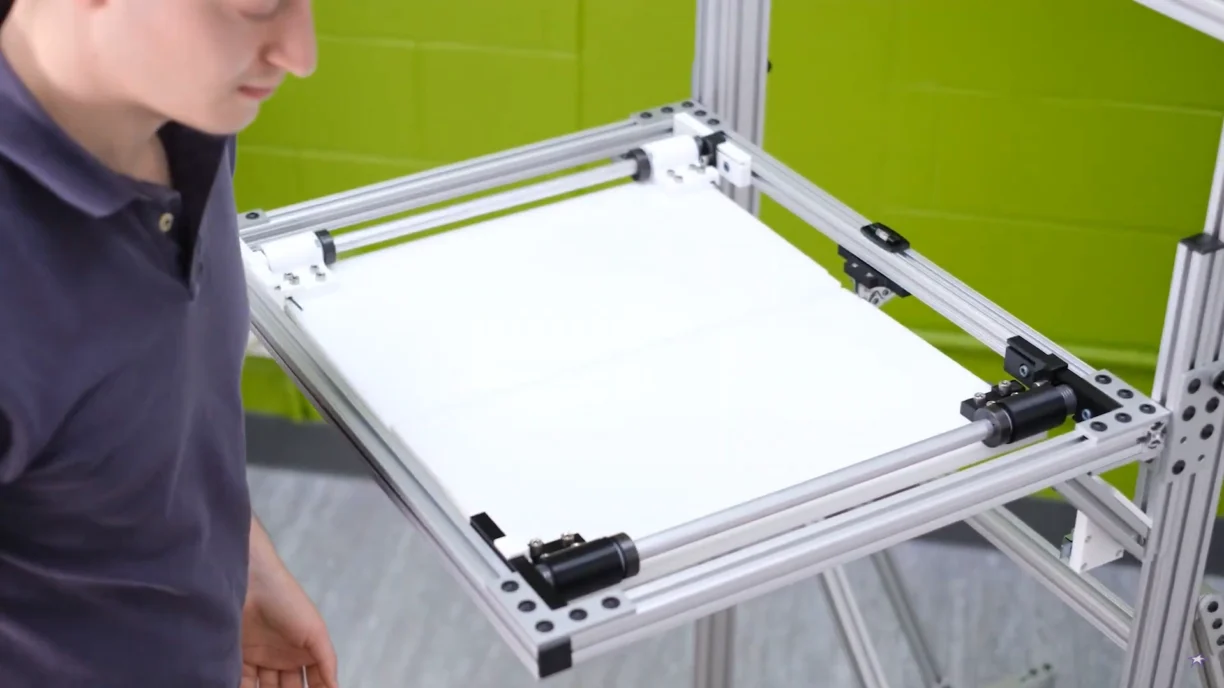

This episode shows how in-house testing setups let engineers explore failure modes before third-party verification. The drop tester featured includes adjustable doors, corner and edge supports, and surfaces for both hardwood and concrete impacts.

Testing Devices and Packaging

During testing, the team drops a medical device on various faces, edges, and corners. The results? Deformation, loose components, and internal rattling—clear signs of structural stress. Eventually, the device fails when dropped on its edge, offering valuable insights for redesign.

Next, they drop test a device package. Each face, edge, and corner is tested—including a downsized box for corner drop demos. A worst-case drop from double height shows whether the packaging holds up under extreme conditions.

Why In-House Drop Testing Matters

Medical device drop testing not only prepares teams for formal third-party tests but also helps identify weaknesses early. It saves time, protects users, and strengthens the final product. And yes—sometimes, it’s just fun to break things on purpose.

Related Resources

Nick and Nigel walk through how sterile disposables are processed and verified before they reach the field.

The FDA agentic AI is making headlines after the agency announced its own internal AI review tool. In this episode of MedDevice by Design, Ariana and Mark discuss what this could mean for medical device submissions and regulatory efficiency.

The sandwich ELISA assay is one of the most common ELISA formats used in diagnostics. Nick and Nigel walk through the method step by step using simple visuals and plain language.